The firing temperature for alumina is not one single value but rather a critical process variable chosen within a specific range. For high-purity alumina powders, an effective temperature to achieve excellent density and fine grain size can be as low as 1350°C. However, the full industrial and scientific range is considerably broader.

The specific firing temperature for alumina is a deliberate choice, typically between 1200°C and 1700°C, made to control a process called sintering. The goal is to achieve the desired final density and microstructure (grain size) in the ceramic part, balancing material properties against processing costs.

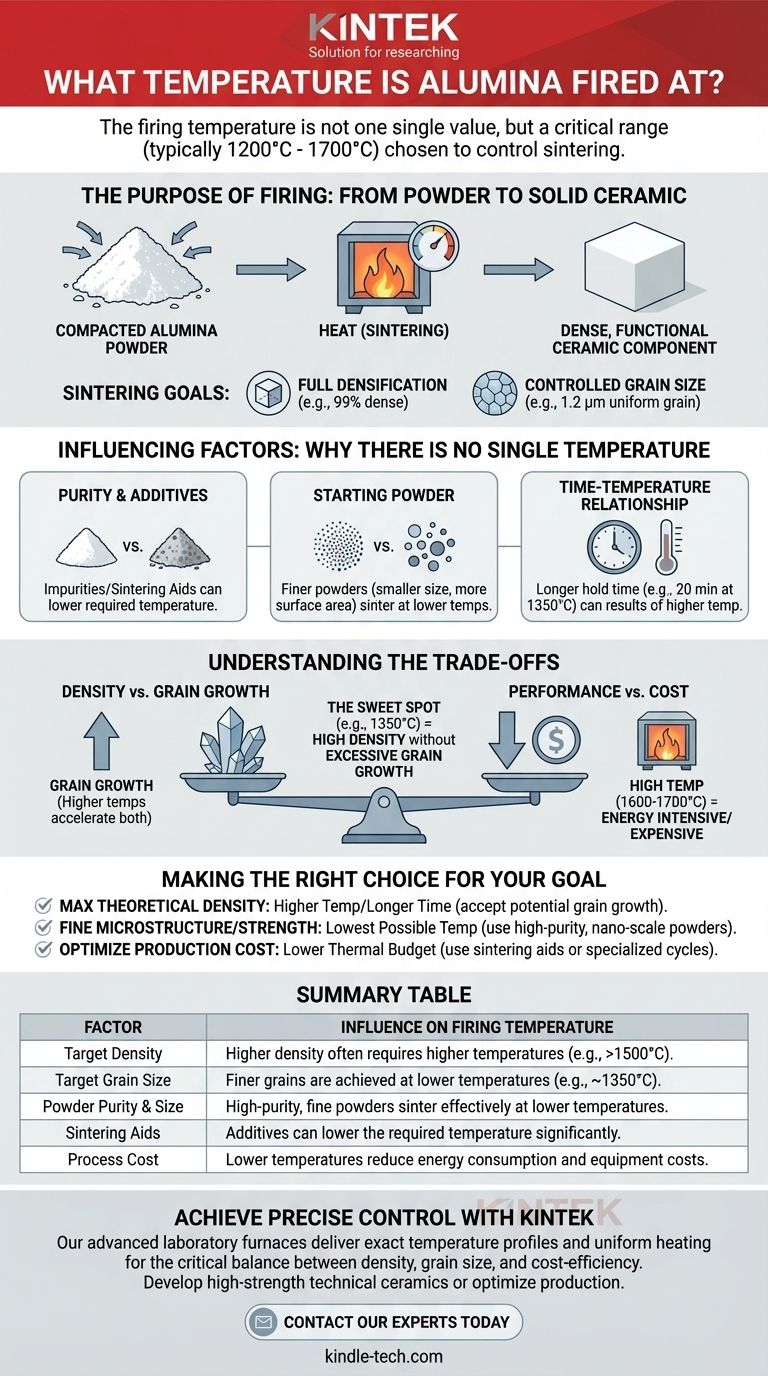

The Purpose of Firing: From Powder to Solid Ceramic

Firing is the crucial step that transforms a compacted powder into a dense, functional ceramic component. This is not simple heating; it is a carefully controlled thermal process with specific goals.

Introducing Sintering

Sintering is the technical term for the firing process. Heat is applied to the compacted alumina powder, causing the individual particles to bond and fuse together, dramatically increasing the material's strength and density without melting it.

The Goal of Full Densification

The primary objective of sintering is to eliminate the empty spaces, or pores, between the initial powder particles. Achieving a high density, such as the 99% of theoretical density noted in research, is critical for maximizing mechanical properties like strength and hardness.

The Role of Grain Size

During sintering, the individual particles coalesce and grow into larger crystalline structures called grains. The final grain size is a key aspect of the material's microstructure. Often, a smaller, more uniform grain size (e.g., 1.2 μm) is desired because it can lead to improved toughness and mechanical strength.

Why There Is No Single Firing Temperature

The ideal temperature depends entirely on the starting material and the desired final properties. Several factors allow engineers and scientists to tune the process.

The Impact of Purity

The reference example uses pure alumina powder. The presence of impurities or deliberate additives (known as sintering aids) can significantly lower the temperature required to achieve full density, sometimes by hundreds of degrees.

The Influence of Starting Powder

Finer starting powders with smaller particle sizes will generally sinter at lower temperatures. This is because smaller particles have more surface area, which provides a greater driving force for the densification process to occur.

The Time-Temperature Relationship

Temperature is not the only variable; time is also critical. Holding a component at a specific temperature for a longer duration (a "soak time") can achieve similar results to firing at a higher temperature for a shorter time. The reference cites a specific time of 20 minutes at 1350°C to achieve its target properties.

Understanding the Trade-offs

Choosing a firing profile is a classic engineering balancing act. Optimizing for one property often comes at the expense of another.

Density vs. Grain Growth

This is the most fundamental trade-off in sintering. While higher temperatures accelerate densification, they also dramatically accelerate grain growth. Pushing for that last percentage point of density can result in overly large grains, potentially compromising the material's final strength. The 1350°C temperature is an excellent example of finding a sweet spot to get high density without excessive grain growth.

Performance vs. Cost

Firing at very high temperatures (e.g., 1600°C - 1700°C) is energy-intensive and requires more complex, expensive furnace equipment. Therefore, there is always a strong economic incentive to achieve the desired properties at the lowest possible temperature.

Making the Right Choice for Your Goal

The optimal firing temperature is defined by your primary objective for the final ceramic component.

- If your primary focus is achieving maximum theoretical density: You will likely need to use higher temperatures or longer hold times, but you must monitor for and accept potential grain growth.

- If your primary focus is maintaining a fine-grained microstructure for maximum strength: You should aim for the lowest possible temperature that achieves your target density, often by using high-purity, nano-scale starting powders.

- If your primary focus is optimizing production cost: You should investigate using sintering aids or specialized firing cycles (like two-step sintering) to lower the overall thermal budget.

Ultimately, determining the ideal firing temperature is a precise balance between the material's starting characteristics and the desired performance of the final ceramic part.

Summary Table:

| Factor | Influence on Firing Temperature |

|---|---|

| Target Density | Higher density often requires higher temperatures (e.g., >1500°C). |

| Target Grain Size | Finer grains are achieved at lower temperatures (e.g., ~1350°C). |

| Powder Purity & Size | High-purity, fine powders sinter effectively at lower temperatures. |

| Sintering Aids | Additives can lower the required temperature significantly. |

| Process Cost | Lower temperatures reduce energy consumption and equipment costs. |

Achieve precise control over your alumina sintering process with KINTEK's advanced laboratory furnaces.

Our equipment is engineered to deliver the exact temperature profiles and uniform heating required to master the critical balance between density, grain size, and cost-efficiency. Whether you are developing high-strength technical ceramics or optimizing production, KINTEK provides the reliable thermal solutions you need.

Ready to perfect your ceramic properties? Contact our experts today to discuss your specific application and discover the ideal furnace for your lab.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the strongest ceramics? Silicon Carbide Leads in Hardness & Thermal Strength

- Why is silicon carbide so important? Unlock Superior Performance in Extreme Conditions

- Is silicon carbide a good electrical insulator? Discover Its Role as a High-Performance Semiconductor

- Are ceramics good electrical insulators? Discover Their Role in High-Performance Applications

- Why is Silicon Carbide high-conductivity ceramic used in reactors? Create a Protective Slag Layer for Biomass Systems

- What material is used for pusher plates? Discover Mullite's Superior Chemical and Thermal Shock Resistance

- Does ceramic break with heat? The Real Culprit is Thermal Shock

- How is sintering done to ceramics? Master the Process for High-Performance Materials