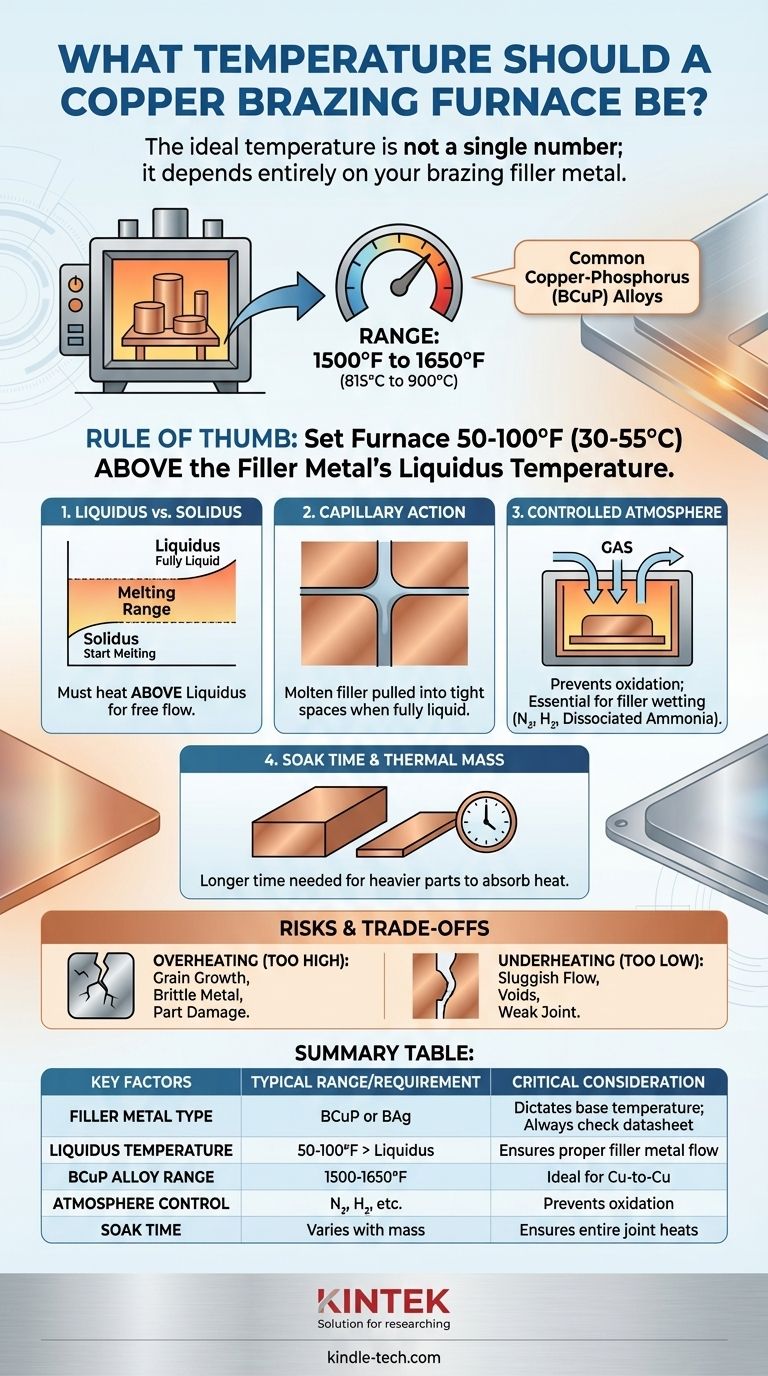

The ideal temperature for a copper brazing furnace is not a single number; it is determined entirely by the specific brazing filler metal (alloy) you are using. The furnace must be set to a temperature that is safely above the filler metal's liquidus (fully liquid) temperature, but well below the melting point of the copper base metal. For common copper-phosphorus alloys, this typically falls within a range of 1500°F to 1650°F (815°C to 900°C).

The fundamental principle of brazing is to melt the filler metal, not the parts being joined. Therefore, you must always consult the technical datasheet for your specific brazing alloy and set your furnace temperature 50-100°F (30-55°C) above its stated liquidus temperature to ensure proper flow.

Why Filler Metal Dictates Temperature

Successful brazing relies on the filler metal becoming fully liquid so it can be drawn into the joint through capillary action. The properties of this filler metal, not the copper itself, are the controlling factor for your furnace settings.

Understanding Liquidus vs. Solidus

Every brazing alloy has a melting range defined by two temperatures. The solidus is the temperature at which the alloy begins to melt, and the liquidus is the temperature at which it becomes completely liquid.

For the filler metal to flow freely and create a strong bond, the entire joint area must be heated above the liquidus temperature.

The Role of Capillary Action

Capillary action is the force that pulls molten filler metal into the tight space between the two copper parts. This phenomenon only works effectively when the filler is fully liquid and fluid.

If the furnace temperature is too low (below the liquidus), the filler will be sluggish and thick, preventing it from completely filling the joint and resulting in a weak connection with voids.

Common Copper Brazing Alloys

Different alloys have different liquidus temperatures. For copper-to-copper joints, BCuP (copper-phosphorus) alloys are extremely common because the phosphorus acts as a fluxing agent, eliminating the need for a separate flux.

For joining copper to other metals like steel or brass, BAg (silver-based) alloys are used, and their temperature requirements will differ significantly. Always check the alloy's specifications.

Setting the Furnace: More Than Just a Number

Achieving the correct temperature is only part of the process. For successful furnace brazing, several other factors are critical to control.

The Importance of a Controlled Atmosphere

Heating copper to brazing temperatures in open air will cause heavy surface oxidation. This oxide layer prevents the filler metal from "wetting" the copper surfaces, making a bond impossible.

Furnace brazing must be done in a protective atmosphere (such as nitrogen, hydrogen, or dissociated ammonia) to displace oxygen and keep the parts clean throughout the heating and cooling cycle.

Soak Time and Thermal Mass

The furnace's temperature display shows the temperature of the air, not the parts. The parts themselves, especially if they are thick or heavy, need time to absorb the heat.

This period is called the soak time—the duration for which the parts are held at the brazing temperature. A longer soak time is required for parts with greater thermal mass to ensure the joint area reaches the necessary temperature for the filler metal to flow.

Understanding the Risks and Trade-offs

Setting the furnace temperature incorrectly in either direction will lead to failed joints.

The Danger of Overheating

Setting the temperature too high wastes energy and creates risks. Excessive heat can cause grain growth in the copper, which can make the metal brittle and weak near the joint.

In extreme cases, you could begin to approach the melting point of copper itself (1984°F / 1085°C), which would destroy the parts.

The Problem with Underheating

Underheating is the most common cause of a poor braze joint. If the furnace temperature is too close to or below the filler's liquidus point, the alloy will not flow properly.

This results in an incomplete fill, leaving gaps and voids that severely compromise the strength and integrity of the final connection.

Making the Right Choice for Your Application

Use the properties of your chosen filler metal as the definitive guide for setting your furnace.

- If your primary focus is joining copper to copper: You are likely using a BCuP alloy. Set your furnace 50-100°F (30-55°C) above the alloy's specified liquidus temperature, putting your process window in the 1500-1650°F (815-900°C) range.

- If your primary focus is brazing copper to a different metal: You will need a different alloy, likely a BAg (silver) alloy. You must consult its datasheet, as its required temperature range will be different from that of BCuP alloys.

- If you are experiencing inconsistent results: First, confirm your furnace is calibrated and providing uniform heat. Second, ensure your protective atmosphere is pure and effectively preventing oxidation on the part surfaces before and during the brazing cycle.

Mastering your furnace temperature and atmosphere is the critical first step toward creating consistently strong and reliable brazed joints.

Summary Table:

| Key Factor | Typical Range/Requirement | Critical Consideration |

|---|---|---|

| Filler Metal Type | BCuP (Copper-Phosphorus) or BAg (Silver) | Dictates the base temperature; always check alloy datasheet |

| Liquidus Temperature | 50-100°F (30-55°C) above alloy's liquidus point | Ensures proper filler metal flow via capillary action |

| Common BCuP Alloy Range | 1500°F to 1650°F (815°C to 900°C) | Ideal for copper-to-copper joints; phosphorus acts as flux |

| Atmosphere Control | Nitrogen, hydrogen, or dissociated ammonia | Prevents oxidation for proper wetting and bonding |

| Soak Time | Varies with part thermal mass | Ensures entire joint reaches target temperature |

Need a furnace that delivers precise temperature control and a reliable atmosphere for flawless copper brazing? KINTEK specializes in high-performance lab furnaces and equipment designed for consistent brazing results. Our experts can help you select the right system for your specific alloys and application requirements. Contact us today to discuss your brazing needs and ensure strong, reliable joints every time!

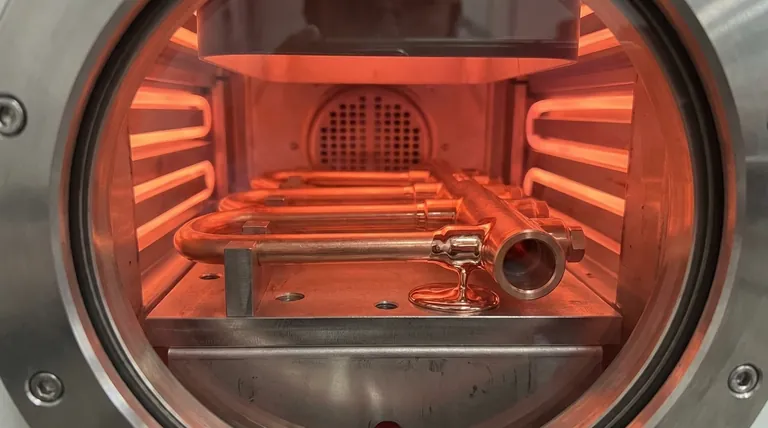

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project