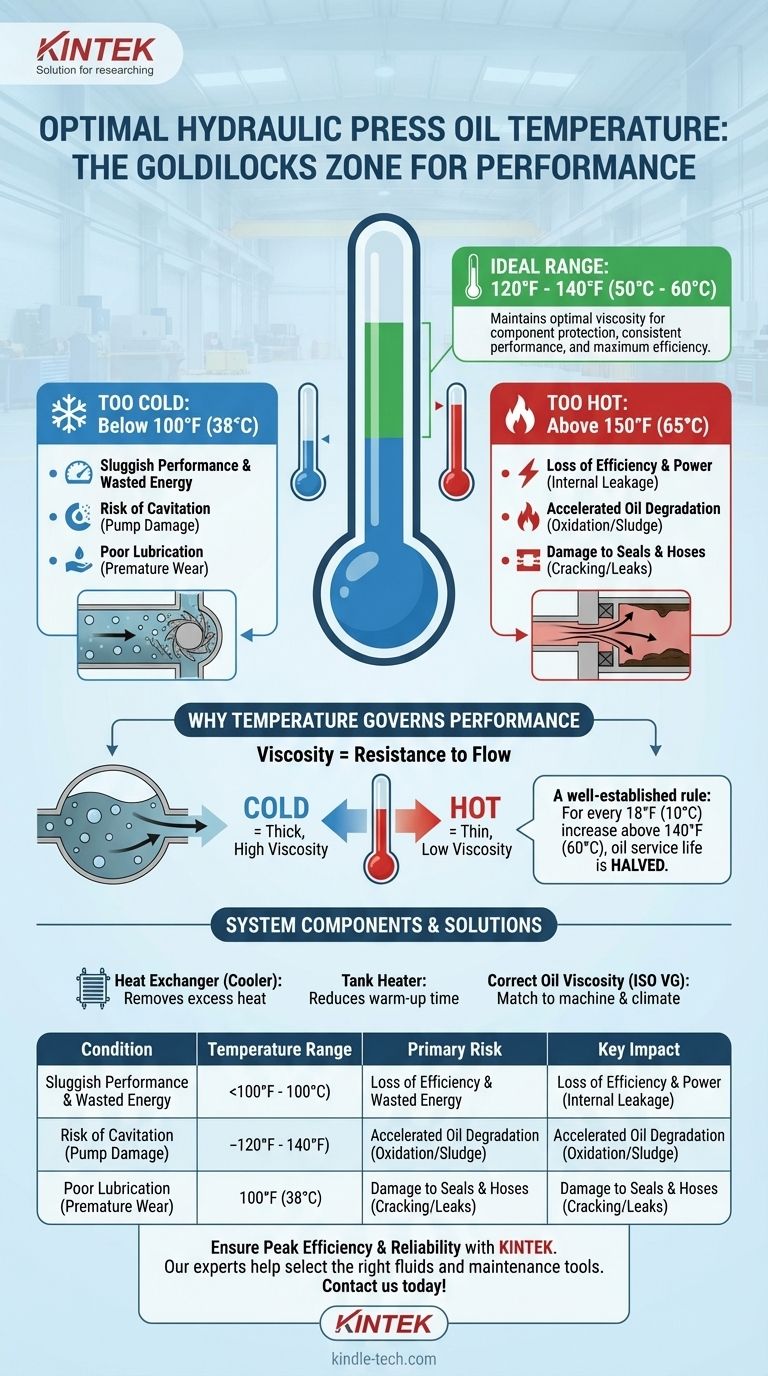

For most industrial hydraulic presses, the ideal operating oil temperature is between 120°F and 140°F (50°C to 60°C). This range ensures the oil maintains its optimal viscosity, which is the single most important factor for protecting components, ensuring consistent performance, and maximizing the efficiency of your machine.

Maintaining the correct hydraulic oil temperature is not about hitting a single number; it's about keeping the oil's viscosity within the narrow range your system was designed for. Operating outside this window, either too hot or too cold, directly compromises performance, efficiency, and the lifespan of your press.

Why Temperature Governs Hydraulic Performance

A hydraulic press operates by transmitting force through an incompressible fluid. The fluid's ability to do this efficiently and without damaging the machinery is almost entirely dependent on its temperature.

The Critical Role of Viscosity

Viscosity is a fluid's resistance to flow. Think of it as the oil's "thickness."

Temperature directly controls viscosity. When oil is cold, it is thick and has a high viscosity. When it's hot, it becomes thin and has a low viscosity.

The "Goldilocks Zone" of Operation

The target temperature range of 120°F - 140°F is the "just right" zone for most common hydraulic oils (e.g., ISO VG 32, 46, 68). In this range, the oil is thin enough to flow easily but thick enough to lubricate and seal properly.

The Dangers of Running Too Cold

Operating a press with oil that is below its ideal range, especially below 100°F (38°C), introduces significant risk and inefficiency.

Sluggish Performance and Wasted Energy

Thick, cold oil is difficult for the pump to move. This resistance causes the press to respond slowly and requires the pump's motor to draw significantly more power, wasting electricity.

The Risk of Cavitation

When the pump struggles to draw in thick oil, a partial vacuum can form at its inlet. This causes dissolved air to be pulled out of the oil, forming vapor bubbles. As these bubbles collapse under pressure inside the pump, they create a powerful micro-jet that erodes and destroys critical internal components—a phenomenon called cavitation.

Poor Lubrication

Cold oil does not flow readily into the tight clearances between moving parts. This starvation of lubricant leads to premature wear on pumps, valves, and cylinders.

The Dangers of Running Too Hot

Overheating, or running the oil above 150°F (65°C), is the most common and destructive temperature-related problem in hydraulic systems.

Loss of Efficiency and Power

As oil gets too hot, its viscosity drops dramatically. This thin oil can easily bypass internal seals in pumps, valves, and cylinders. This internal leakage means a portion of the pump's flow is wasted, resulting in slower cycle times and a reduced ability to build and hold pressure.

Accelerated Oil Degradation

Heat is a catalyst for oxidation, the primary way hydraulic oil breaks down. Oxidation creates sludge and varnish that clog filters, stick valves, and coat internal surfaces, restricting flow and heat dissipation.

A well-established rule is that for every 18°F (10°C) increase in temperature above 140°F (60°C), the service life of the oil is cut in half.

Damage to Seals and Hoses

High temperatures cause elastomeric seals (O-rings, gaskets) to become hard and brittle. This leads to cracking and permanent leaks, which can result in costly downtime and repairs.

Understanding the Trade-offs and System Components

Achieving the correct temperature is a function of machine design and maintenance. No system runs at 100% efficiency; the wasted energy is converted directly into heat.

The Job of the Heat Exchanger

Nearly all continuous-duty hydraulic presses have a heat exchanger (cooler). Its sole purpose is to remove the excess heat generated by system inefficiencies. If your system is overheating, the first place to check is the cooler. It may be undersized for the job, or its fins may be clogged with dirt, preventing proper airflow.

Choosing the Right Oil Viscosity

The oil's viscosity grade (ISO VG) must be matched to your machine's requirements and your ambient climate. Using an oil that is too thick or too thin for your operating conditions will make it impossible to maintain the correct viscosity at the target temperature. Always consult the press manufacturer's recommendation.

Making the Right Choice for Your Operation

Use your system's temperature gauge as a primary diagnostic tool. It provides a real-time window into the health and efficiency of your press.

- If you experience slow, sluggish operation on startup: Your oil is likely too cold. Investigate if a reservoir (tank) heater is needed for your climate to reduce warm-up time and prevent cold-start damage.

- If you notice a loss of speed or force as the machine runs for a while: Your oil is overheating. Immediately inspect your heat exchanger for blockages and ensure it is functioning correctly.

- For maximum reliability and component life: Make it a standard practice to monitor the temperature and ensure it stabilizes within the 120°F to 140°F (50°C to 60°C) range during normal operation.

Treating your hydraulic system's temperature not as a target, but as a vital sign, is the key to ensuring its long-term health and reliability.

Summary Table:

| Condition | Temperature Range | Primary Risk | Key Impact |

|---|---|---|---|

| Too Cold | Below 100°F (38°C) | Cavitation, Poor Lubrication | Slow operation, Pump damage, Wear |

| Ideal Range | 120°F - 140°F (50°C - 60°C) | Optimal Viscosity | Efficient operation, Maximum component life |

| Too Hot | Above 150°F (65°C) | Oil Oxidation, Internal Leakage | Loss of power, Seal failure, Sludge formation |

Ensure your hydraulic press operates at peak efficiency and reliability.

Maintaining the correct oil temperature is critical for protecting your investment. KINTEK specializes in lab equipment and consumables, including solutions for industrial hydraulic systems. Our experts can help you select the right fluids and maintenance tools to keep your press running smoothly within the ideal temperature range, preventing costly downtime and repairs.

Contact us today to discuss your specific needs and how we can support your laboratory's hydraulic press performance.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy