Pyrolysis is a versatile thermal decomposition process that is suitable for a wide range of organic-based waste materials. It is most effective for treating carbon-rich feedstocks like various forms of plastic and biomass, converting them into valuable energy products and chemical feedstocks in an oxygen-free environment.

The suitability of a waste material for pyrolysis hinges on its chemical composition. It is an ideal solution for materials with high organic content and low moisture, primarily targeting complex plastics that are difficult to recycle and various forms of biomass.

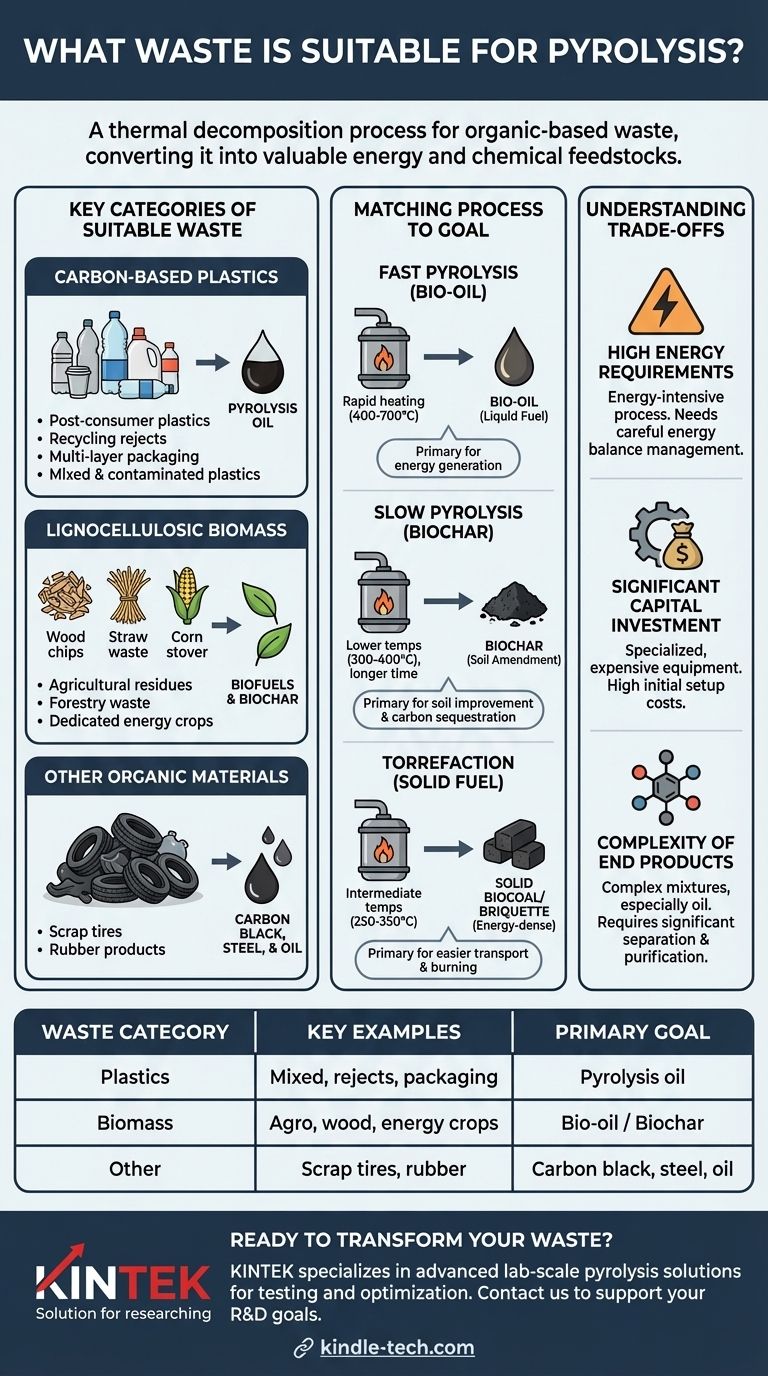

Key Categories of Suitable Waste

Pyrolysis is not a one-size-fits-all solution. The ideal feedstock is a material whose core value can be unlocked through thermal decomposition, turning a low-value or negative-value waste into a higher-value product like fuel or a chemical precursor.

Carbon-Based Plastics

Plastics are long-chain hydrocarbons, making them an excellent feedstock for producing pyrolysis oil, which is similar to crude oil. This process is particularly valuable for waste streams that are difficult to handle through traditional means.

Suitable plastic wastes include:

- Post-consumer plastics and segregated plastics from municipal solid waste (MSW).

- Rejects from mechanical recycling facilities that are otherwise destined for landfill.

- Multi-layer and composite packaging which cannot be easily separated.

- Mixed and contaminated plastics, including those with PET/PVC content that can disrupt other recycling processes.

Lignocellulosic Biomass

Biomass refers to any organic matter from plants and animals. Pyrolysis converts this material into useful biofuels and biochar, providing a sustainable waste management technique.

This broad category includes materials like:

- Agricultural residues (straw, corn stover)

- Forestry waste (wood chips, sawdust)

- Dedicated energy crops

Other Organic Materials

Beyond the two main categories, pyrolysis can effectively process other specific organic waste streams.

Most notably, this includes scrap tires and other rubber products. Pyrolysis breaks down the rubber into carbon black, steel, and a hydrocarbon oil, recovering valuable raw materials from a notoriously difficult waste stream.

Matching the Process to the Goal

The specific type of pyrolysis technology used is determined by the desired end product. The heating rate and temperature directly influence whether the output is primarily liquid, solid, or gas.

Fast Pyrolysis for Bio-Oil

This process involves rapid heating to high temperatures (400-700°C) in a matter of seconds.

This method maximizes the production of bio-oil, a liquid fuel. It is the preferred technology when the primary goal is energy generation from biomass.

Slow Pyrolysis for Biochar

In contrast, slow pyrolysis involves heating biomass at lower temperatures (300-400°C) over a much longer period.

This process is optimized to produce biochar, a stable, carbon-rich solid. Biochar is primarily used as a soil amendment to improve fertility and sequester carbon.

Torrefaction for Solid Fuel

Torrefaction occurs at intermediate temperatures (250-350°C) and is sometimes considered a mild form of pyrolysis.

The goal is to produce a solid, energy-dense biocoal or briquette. This product has improved fuel characteristics compared to raw biomass, making it easier to transport and burn.

Understanding the Practical Trade-offs

While powerful, pyrolysis is a complex industrial process with significant challenges that must be considered for any project to be viable.

High Energy Requirements

Pyrolysis is an energy-intensive process. The system's overall energy balance must be carefully managed to ensure it produces more energy than it consumes, especially when processing high-moisture feedstocks.

Significant Capital Investment

The equipment required to operate at high temperatures in an oxygen-free environment is specialized and expensive. This results in high initial capital costs for setting up a pyrolysis plant.

Complexity of End Products

The outputs of pyrolysis, especially the liquid oil, are often complex mixtures of hundreds of different chemical compounds. They typically require significant separation and purification before they can be used as fuel or chemical feedstock, which adds cost and complexity to the overall operation.

Making the Right Choice for Your Goal

Selecting the correct waste material and process is critical for a successful pyrolysis operation. Your end goal should dictate your choice of feedstock.

- If your primary focus is liquid fuel production: Fast pyrolysis of low-moisture biomass or clean plastic streams is the most direct route to producing bio-oil.

- If your primary focus is soil improvement and carbon sequestration: Slow pyrolysis of woody biomass is the ideal pathway to create stable, high-quality biochar.

- If your primary focus is managing difficult plastic waste: Pyrolysis provides a robust solution for mixed or contaminated plastics that mechanical recycling cannot handle.

Ultimately, a successful pyrolysis strategy depends on matching a specific waste stream's composition with a process designed to achieve a clear economic or environmental objective.

Summary Table:

| Waste Category | Key Examples | Primary Pyrolysis Goal |

|---|---|---|

| Carbon-Based Plastics | Mixed plastics, recycling rejects, multi-layer packaging | Produce pyrolysis oil (similar to crude oil) |

| Lignocellulosic Biomass | Agricultural residues, wood chips, energy crops | Produce bio-oil (fast pyrolysis) or biochar (slow pyrolysis) |

| Other Organic Materials | Scrap tires, rubber products | Recover carbon black, steel, and oil |

Ready to transform your waste stream into valuable products?

KINTEK specializes in advanced pyrolysis solutions for laboratories and research facilities. Whether you are developing new processes for plastic waste, biomass conversion, or tire recycling, our high-quality lab-scale pyrolysis reactors and consumables provide the precision and reliability you need.

We help you:

- Test and optimize pyrolysis parameters for your specific feedstock.

- Accelerate R&D with equipment designed for accurate, reproducible results.

- Scale your process from the lab to pilot plant with confidence.

Contact us today to discuss how KINTEK's lab equipment can support your pyrolysis research and development goals. Get in touch via our contact form.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products