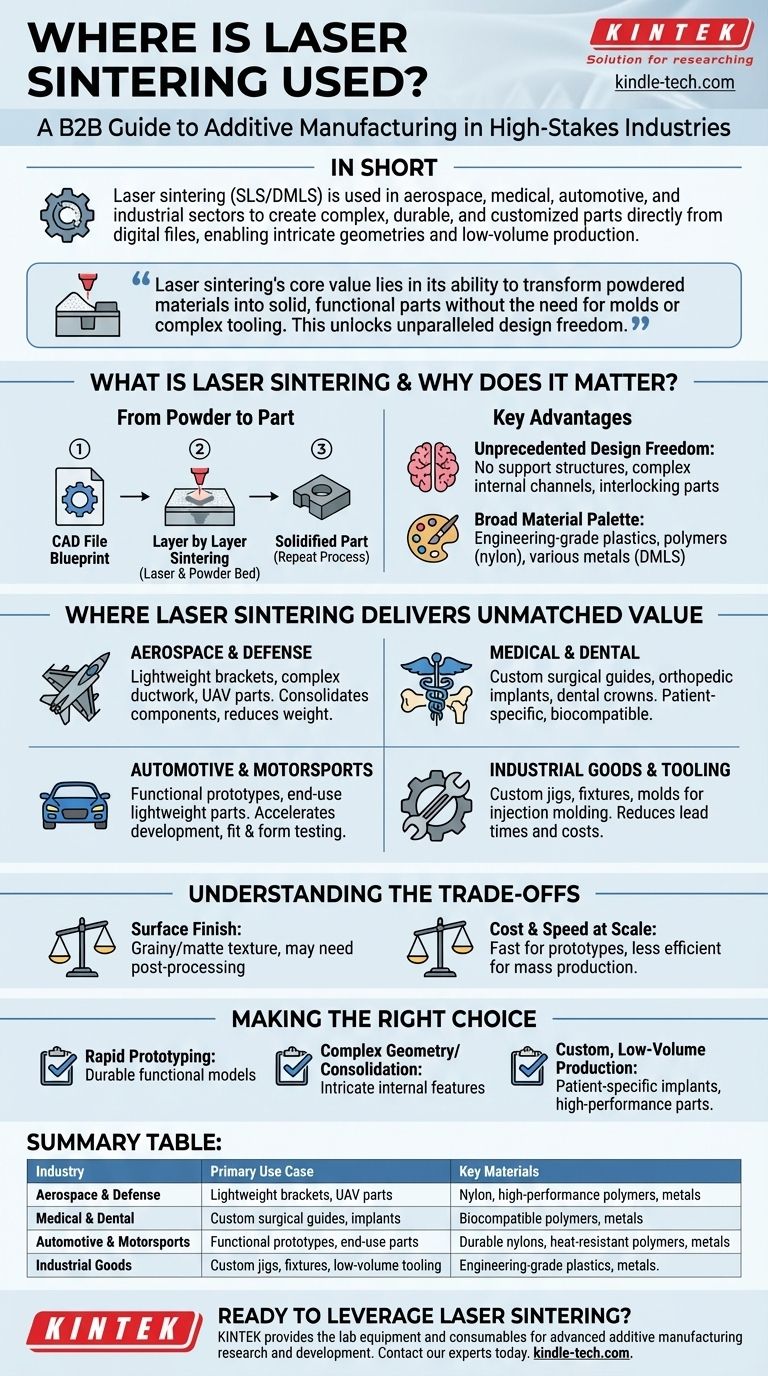

In short, laser sintering is used in high-stakes industries like aerospace, medical, automotive, and industrial manufacturing to create complex, durable, and often customized parts directly from a digital design file. This additive manufacturing process excels where traditional methods fall short, enabling the production of intricate geometries and low-volume functional components.

Laser sintering’s core value lies in its ability to transform powdered materials into solid, functional parts without the need for molds or complex tooling. This unlocks unparalleled design freedom, making it the ideal choice for rapid prototyping, custom manufacturing, and producing high-performance components.

What is Laser Sintering and Why Does it Matter?

Laser sintering, often called Selective Laser Sintering (SLS), is a mature and reliable form of 3D printing. Understanding its fundamental process reveals why it has become so critical in modern engineering and manufacturing.

From Powder to Part: The Basic Process

The technology operates by using a powerful, high-precision laser to fuse, or sinter, powdered material together layer by layer. A computer-aided design (CAD) file acts as the blueprint, guiding the laser to precisely trace the cross-section of a part onto a bed of powder, solidifying it.

After one layer is complete, a new layer of powder is spread over the top, and the process repeats until the entire object is built.

Key Advantage: Unprecedented Design Freedom

Because the part is always supported by the surrounding unused powder, laser sintering does not require the dedicated support structures common in other 3D printing methods. This enables the creation of extremely complex internal channels, moving interlocking parts printed in a single piece, and organic shapes that would be impossible to machine or mold.

Key Advantage: A Broad Material Palette

Laser sintering is not limited to one type of material. It works with a wide range of engineering-grade plastics and polymers (like nylon), as well as various metals (a process often called Direct Metal Laser Sintering or DMLS). This versatility allows for the creation of parts with specific properties, from flexibility to high strength and heat resistance.

Where Laser Sintering Delivers Unmatched Value

The unique capabilities of laser sintering make it an essential tool in industries where performance, customization, and speed are paramount.

Aerospace & Defense

In aerospace, every gram of weight matters. Laser sintering is used to produce lightweight yet strong components, such as brackets, complex ductwork, and unmanned aerial vehicle (UAV) parts. It allows engineers to consolidate multiple components into a single, optimized part, reducing assembly time and potential points of failure.

Medical & Dental

This technology has revolutionized patient-specific care. It is used to create custom surgical guides, orthopedic implants (like knee or hip replacements), and dental crowns, all tailored perfectly to an individual's anatomy from a CT or MRI scan. The ability to use biocompatible materials is critical here.

Automotive & Motorsports

From initial concept to the racetrack, laser sintering accelerates automotive development. It is used extensively for creating functional prototypes for fit, form, and performance testing. In high-performance motorsports, it's used to manufacture low-volume, end-use parts that are lightweight and can withstand extreme conditions.

Industrial Goods & Tooling

Laser sintering is also used to improve traditional manufacturing. Companies use it to quickly produce custom jigs, fixtures, and even molds for injection molding, drastically reducing lead times and costs associated with conventional tool and die making.

Understanding the Trade-offs

While powerful, laser sintering is not a universal solution. Being aware of its limitations is key to using it effectively.

Surface Finish and Porosity

Parts produced via laser sintering typically have a slightly grainy or matte surface finish. While fully functional, they often require secondary post-processing steps like sanding, polishing, or coating if a smooth, cosmetic surface is needed.

Cost and Speed at Scale

For producing a single, complex prototype, laser sintering is incredibly fast and cost-effective. However, for mass-producing thousands of simple parts, traditional methods like injection molding are significantly faster and cheaper on a per-unit basis.

Making the Right Choice for Your Project

Choosing the right manufacturing process depends entirely on your project's specific goals.

- If your primary focus is rapid prototyping: Laser sintering is ideal for creating durable, functional models for real-world testing in a matter of days.

- If your primary focus is complex geometry or part consolidation: Use this technology to build parts with intricate internal features that are impossible to create with any other method.

- If your primary focus is custom, low-volume production: It is the go-to solution for manufacturing patient-specific medical implants or high-performance components where customization is key.

Ultimately, laser sintering is a transformative manufacturing tool that removes traditional constraints, enabling engineers to design and build for optimal function rather than for manufacturing feasibility.

Summary Table:

| Industry | Primary Use Case | Key Materials |

|---|---|---|

| Aerospace & Defense | Lightweight brackets, complex ductwork, UAV parts | Nylon, high-performance polymers, metals |

| Medical & Dental | Custom surgical guides, orthopedic implants, dental crowns | Biocompatible polymers, metals (e.g., titanium) |

| Automotive & Motorsports | Functional prototypes, end-use lightweight parts | Durable nylons, heat-resistant polymers, metals |

| Industrial Goods | Custom jigs, fixtures, low-volume tooling | Engineering-grade plastics, metals |

Ready to leverage laser sintering for your lab's projects? KINTEK specializes in providing the lab equipment and consumables needed to support advanced additive manufacturing research and development. Whether you're prototyping new medical devices or testing materials for aerospace, our solutions help you achieve precision and reliability. Contact our experts today to discuss how we can equip your lab for success.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology