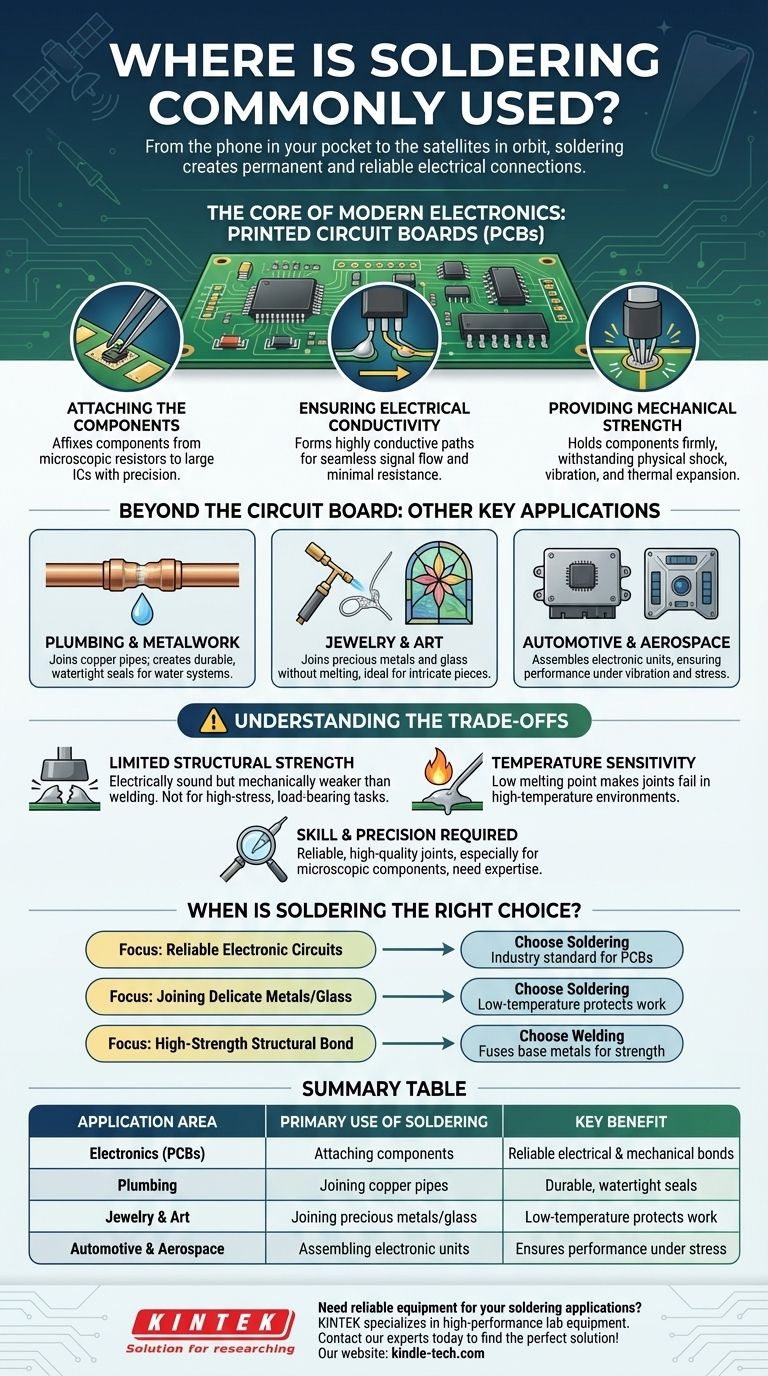

From the phone in your pocket to the satellites in orbit, soldering is the fundamental process used to create permanent and reliable electrical connections. Its most common and critical application is in the assembly of Printed Circuit Boards (PCBs), the green boards that form the foundation of virtually all modern electronic devices.

Soldering is more than just a joining technique; it is the essential bridge that transforms individual electronic components into a functional, interconnected system by providing both mechanical strength and electrical conductivity.

The Core of Modern Electronics: Printed Circuit Boards (PCBs)

The primary role of soldering is to bring electronic circuits to life. It is the standard method for attaching components to a PCB, enabling complex devices to function reliably.

Attaching the Components

Soldering is used to affix a vast array of components, from microscopic resistors and capacitors to large Integrated Circuits (ICs), onto the copper pads of a circuit board. This precision is essential for the dense and intricate layouts of modern electronics.

Ensuring Electrical Conductivity

The solder itself is a metal alloy with a low melting point that, once solidified, forms a highly conductive path. This ensures that electrical signals can flow seamlessly between the component and the circuit board traces with minimal resistance.

Providing Mechanical Strength

A well-formed solder joint provides a strong mechanical bond. It holds the component firmly in place, allowing the device to withstand physical shock, vibration, and thermal expansion without the connection failing.

Beyond the Circuit Board: Other Key Applications

While electronics are its primary domain, the principles of soldering are applied in various other fields, from industrial applications to fine arts.

Plumbing and Metalwork

In plumbing, soldering is used to join copper pipes and fittings. This process creates a durable, watertight seal capable of withstanding the pressure within a water system for decades.

Jewelry Making and Repair

Jewelers use soldering to join precious metals like gold and silver. The technique's low-temperature nature allows them to create or repair intricate pieces without melting or damaging the delicate metalwork itself.

Stained Glass and Art

Artists use soldering to join the edges of cut glass pieces in stained glass work. The molten solder flows into the gaps between the copper foil-wrapped glass, creating the distinct lines that hold the artwork together.

Understanding the Trade-offs

Soldering is a versatile and essential process, but it is not the solution for every joining task. Understanding its limitations is key to using it correctly.

Limited Structural Strength

Soldering creates a bond that is electrically sound but mechanically weaker than other methods. For high-stress, load-bearing applications, welding is the appropriate choice, as it fuses the base metals themselves to create a much stronger joint.

Temperature Sensitivity

The low melting point of solder is its key advantage, but also a limitation. Soldered joints are not suitable for high-temperature environments where they could soften or melt, causing the connection to fail.

Skill and Precision Required

While simple soldering is easy to learn, creating reliable, high-quality joints—especially with microscopic surface-mount components—requires significant skill, precision, and the right equipment to avoid damaging components or creating faulty connections.

When is Soldering the Right Choice?

Choosing the correct joining method depends entirely on your application's requirements for strength, conductivity, and temperature resistance.

- If your primary focus is creating reliable electronic circuits: Soldering is the non-negotiable industry standard for attaching components to PCBs.

- If your primary focus is joining delicate metals without heat damage: The low-temperature nature of soldering makes it ideal for jewelry, art, and other fine metalwork.

- If your primary focus is creating a high-strength structural bond: You should look to welding, as soldering lacks the necessary mechanical strength for load-bearing joints.

Understanding where and why soldering is used is the first step toward leveraging this foundational connecting technology for any project.

Summary Table:

| Application Area | Primary Use of Soldering | Key Benefit |

|---|---|---|

| Electronics (PCBs) | Attaching components to circuit boards | Creates reliable electrical & mechanical bonds |

| Plumbing | Joining copper pipes and fittings | Forms durable, watertight seals |

| Jewelry & Art | Joining precious metals or stained glass | Low-temperature process protects delicate work |

| Automotive & Aerospace | Assembling and repairing electronic control units | Ensures performance under vibration and stress |

Need reliable equipment for your soldering applications? KINTEK specializes in high-performance lab equipment and consumables for electronics manufacturing, research, and repair. Whether you're assembling complex PCBs or working on delicate prototypes, our precision tools ensure strong, consistent joints. Contact our experts today to find the perfect soldering solution for your laboratory's needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Gold Electrochemical Sheet Electrode Gold Electrode

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- High Purity Gold Platinum Copper Iron Metal Sheets

- Electrode Fixture for Electrochemical Experiments

People Also Ask

- What is the pressure range for sputtering? Optimize Your Thin Film Deposition Process

- What are the uses of pyrolysis bio-oil? A Guide to Fuel, Chemical, and Power Applications

- What are the sources of materials for biochar production? From Wood to Waste, Choose the Right Feedstock

- What are the advantages of microwave pyrolysis? Faster, More Efficient Waste Conversion

- What is the sputtering process of thin films? A Guide to High-Quality PVD Deposition

- What materials are sintered steel? Unlock the Secrets of Powder-Based Steel Manufacturing

- What is the thermal conductivity of graphite? A Guide to Its Vast Range and Applications

- How do precision dripping systems or syringes contribute to sodium alginate bead formation? Achieve Scientific Uniformity