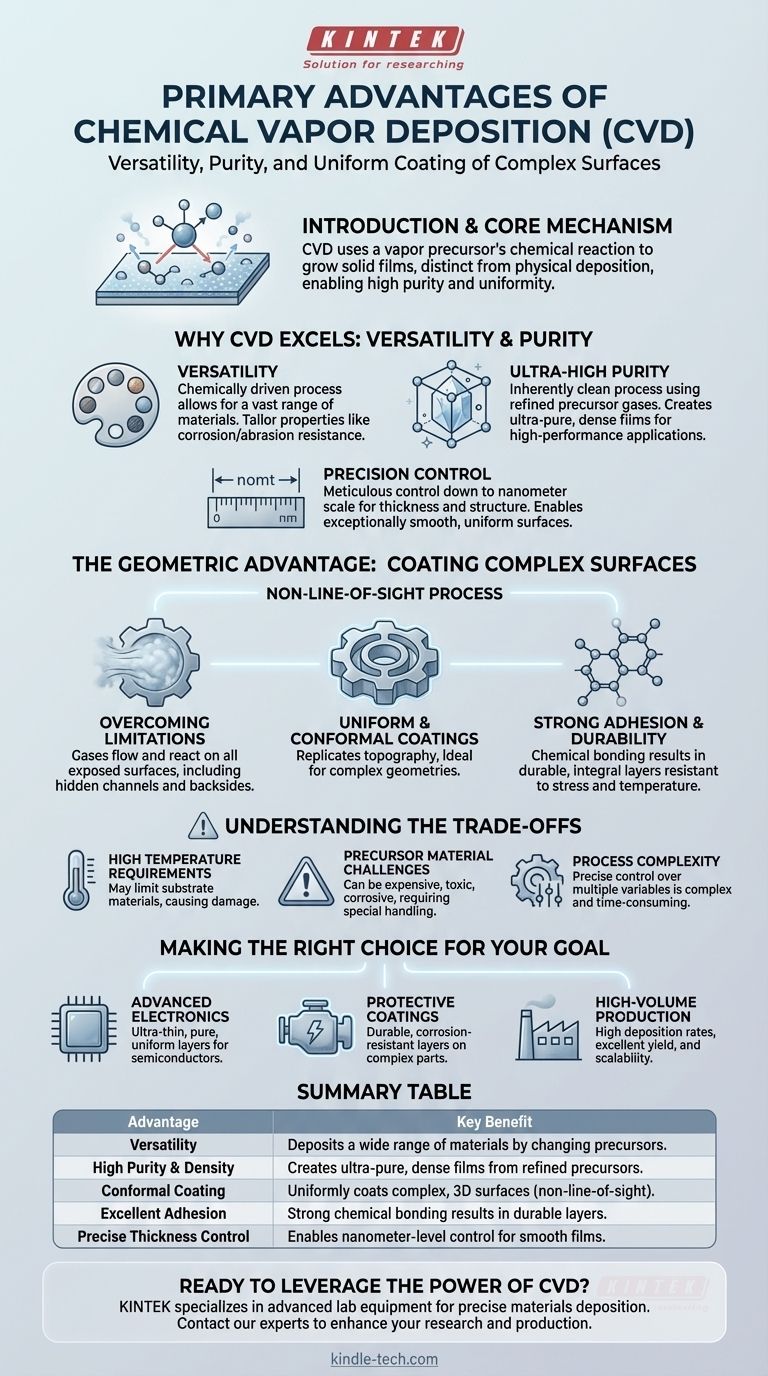

The primary advantages of Chemical Vapor Deposition (CVD) are its versatility, the exceptional purity and quality of the films it produces, and its unique ability to uniformly coat complex, three-dimensional surfaces. This combination of attributes makes CVD a cornerstone technology in industries ranging from semiconductors to aerospace, where precise, durable, and conformal material layers are critical.

Chemical Vapor Deposition's core strength lies in its process: using a chemical reaction from a vapor precursor to grow a solid film. This foundational difference from physical deposition methods is the source of its most significant advantages, enabling the creation of highly pure, uniform coatings on virtually any shape.

Why CVD Excels: Versatility and Purity

The power of CVD begins with its fundamental mechanism. Unlike processes that physically sputter or evaporate material onto a surface, CVD builds new material layer by layer through controlled chemical reactions.

A Foundation Built on Chemical Reactions

Because the process is chemically driven, CVD is incredibly versatile. By changing the precursor gases, temperature, and pressure, you can deposit a vast range of materials, including metals, ceramics, and various composites.

This allows engineers to precisely tailor the properties of the final coating, optimizing for characteristics like corrosion resistance, abrasion resistance, or specific electrical conductivity.

Achieving Ultra-High Purity

The CVD process is inherently clean. Precursor gases can be refined to exceptionally high purity levels, which directly translates into the creation of ultra-pure and dense solid films.

This purity is essential for high-performance applications, such as ensuring the required electrical and thermal conductivity in electronic components or the biocompatibility of medical implants.

Precision Control Down to the Nanometer

CVD allows for meticulous control over film thickness and structure. The process can be managed to create layers from microns thick down to a single atomic layer, a level of precision required for modern electrical circuits and nanotechnology.

This fine control results in exceptionally smooth and uniform surfaces compared to many alternative coating methods.

The Geometric Advantage: Coating Complex Surfaces

One of the most distinct advantages of CVD is its ability to deposit films on non-planar objects with exceptional uniformity.

Overcoming Line-of-Sight Limitations

CVD is a non-line-of-sight process. The precursor gases flow and diffuse around the target object, reacting with all exposed surfaces, even those in hidden channels or on the backside.

Think of it like a pervasive fog that settles evenly on every part of a complex structure, as opposed to a spray paint can that can only coat what it can directly "see."

Uniform and Conformal Coatings

This non-line-of-sight nature enables the creation of highly conformal coatings that perfectly replicate the topography of the substrate. CVD can uniformly coat intricate parts, inside and out, making it ideal for components with complex geometries.

Strong Adhesion and Durability

The chemical bonding that occurs at the surface during deposition results in coatings with excellent adhesion. These layers become an integral part of the component, creating a durable surface that can withstand high-stress environments and extreme temperature variations.

Understanding the Trade-offs

While powerful, CVD is not without its challenges. True expertise requires understanding its limitations.

High Temperature Requirements

Many CVD processes require high substrate temperatures to initiate the necessary chemical reactions. This can limit the types of materials that can be coated, as some substrates may melt, warp, or be otherwise damaged by the heat.

Precursor Material Challenges

The precursor chemicals used in CVD can be expensive, toxic, corrosive, or pyrophoric (igniting in air). This necessitates complex and costly safety, storage, and handling protocols.

Process Complexity

Achieving the perfect film requires precise control over multiple variables, including temperature, pressure, gas flow rates, and reactor geometry. Optimizing a CVD process can be complex and time-consuming.

Making the Right Choice for Your Goal

Selecting a deposition technology depends entirely on your project's primary objective.

- If your primary focus is advanced electronics: CVD is the superior choice for creating the ultra-thin, highly pure, and perfectly uniform layers required for semiconductor manufacturing.

- If your primary focus is protective coatings on complex parts: CVD's non-line-of-sight capability makes it ideal for delivering durable, corrosion-resistant layers on intricate components that physical methods cannot cover evenly.

- If your primary focus is high-volume, scalable production: CVD offers high deposition rates, excellent yield, and proven scalability, making it an efficient choice for industrial manufacturing.

Ultimately, CVD's ability to transform a gas into a high-performance solid film makes it one of the most powerful and adaptable tools in modern materials science.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Versatility | Deposits a wide range of materials (metals, ceramics) by changing precursor gases. |

| High Purity & Density | Creates ultra-pure, dense films from refined precursor gases. |

| Conformal Coating | Uniformly coats complex, 3D surfaces (non-line-of-sight process). |

| Excellent Adhesion | Strong chemical bonding results in durable, integrated layers. |

| Precise Thickness Control | Enables nanometer-level control for smooth, uniform films. |

Ready to leverage the power of CVD for your lab's coating needs?

KINTEK specializes in providing advanced lab equipment and consumables for precise materials deposition. Whether you are developing semiconductors, creating protective coatings for aerospace components, or conducting cutting-edge materials research, our expertise can help you achieve superior results.

Contact our experts today to discuss how our solutions can enhance your research and production capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the function of grinding WC-Co substrate with diamond powder before HFCVD? Achieve Superior Film Nucleation

- What is the importance of chemical Vapour deposition? Unlock High-Purity, High-Performance Materials

- What is the mechanism of MOCVD? Precise Thin Film Deposition for High-Performance Semiconductors

- What is the low temperature growth of carbon nanotubes? Synthesize CNTs on Sensitive Electronics

- How is CVD coating done? A Step-by-Step Guide to Superior Surface Engineering

- What is the newly discovered mechanism for diamond formation during CVD? Explore the Graphite-to-Diamond Transition

- Which type of sputtering system is used to deposit ZnO thin film? Discover RF Magnetron Sputtering for Superior Films

- What is the role of a high-frequency induction power supply in a CVD system? Powering ZrC Growth at 1600°C+