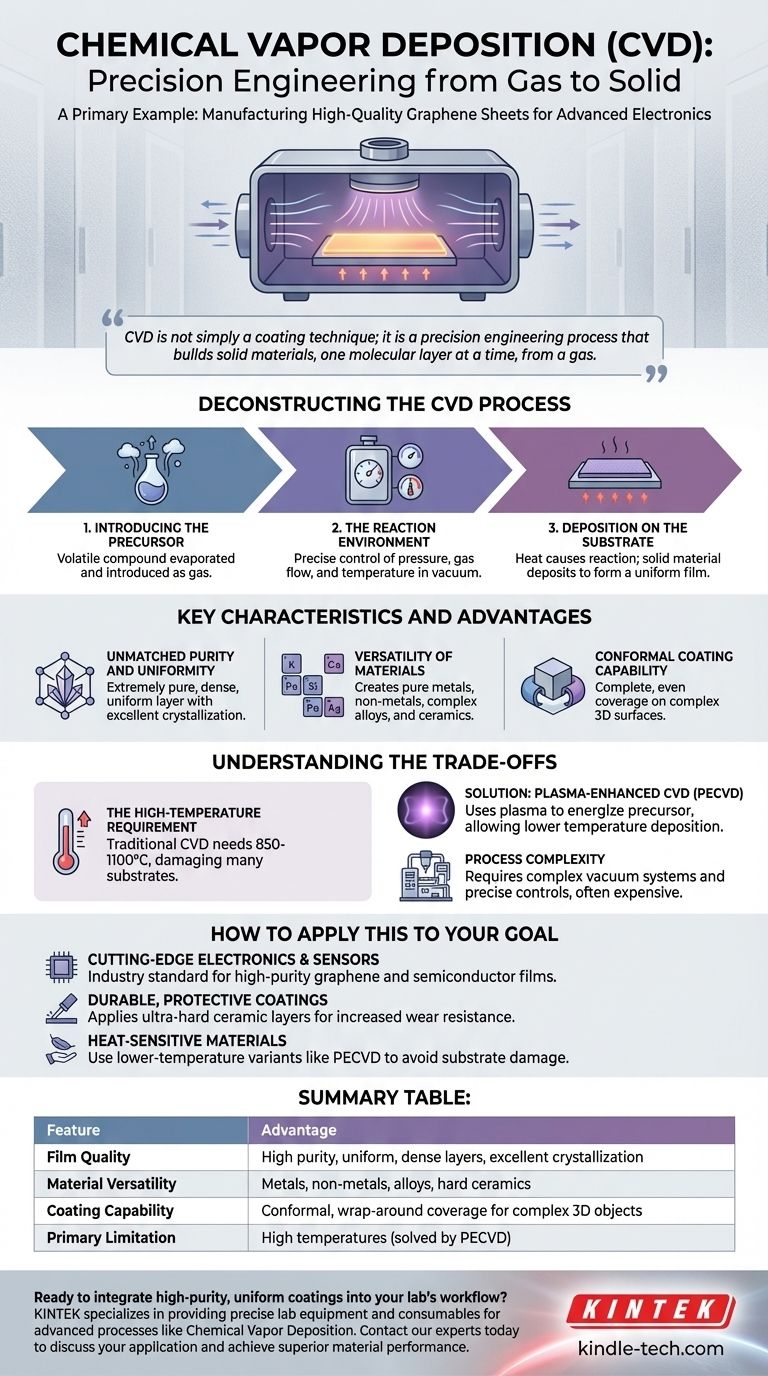

A primary example of chemical vapor deposition (CVD) is its use in manufacturing the high-quality, large-area graphene sheets required for advanced electronics and sensors. This method is considered a leading approach because it can produce uniform, single-atom-thick layers with a very low number of defects.

Chemical Vapor Deposition is not simply a coating technique; it is a precision engineering process that builds solid materials, one molecular layer at a time, from a gas. This control is what allows it to create the foundational materials for much of our modern technology.

Deconstructing the CVD Process

At its core, Chemical Vapor Deposition is a method for creating a thin, solid film on a surface, known as a substrate. The entire process takes place under vacuum and relies on a precise sequence of events.

Step 1: Introducing the Precursor

A volatile compound, called a precursor, is the source material for the final film. This material is evaporated and introduced into a reaction chamber as a gas.

Step 2: The Reaction Environment

The precursor gas flows into a sealed chamber containing the substrate. The chamber's conditions—such as pressure, gas flow, and temperature—are meticulously controlled.

Step 3: Deposition on the Substrate

The substrate is heated to a specific reaction temperature. This energy causes the precursor gas to react or decompose, and the resulting solid material deposits onto the substrate's surface, forming a thin, uniform film.

Key Characteristics and Advantages

CVD is valued for its ability to produce films with specific, high-performance properties that are difficult to achieve with other methods.

Unmatched Purity and Uniformity

The controlled vacuum environment ensures the deposited film is extremely pure. Over time, the coating builds up evenly, resulting in a dense, uniform layer with excellent crystallization and low internal stress.

Versatility of Materials

CVD is incredibly versatile. The process can be adapted to create a wide variety of deposits, including pure metal films, non-metal films, complex alloys, and hard ceramic or compound layers.

Conformal Coating Capability

A key strength of CVD is its ability to create a "wrap-around" coating. The gaseous precursor can reach and deposit on all exposed surfaces of a complex, three-dimensional object, ensuring complete and even coverage.

Understanding the Trade-offs

While powerful, CVD is not without its limitations. Understanding these trade-offs is crucial for choosing the right manufacturing process.

The High-Temperature Requirement

Traditional thermal CVD often requires very high reaction temperatures, typically between 850-1100°C. Many substrate materials cannot withstand this level of heat without being damaged or melting.

The Solution: Lower-Temperature Variants

To overcome the heat limitation, specialized variants have been developed. Plasma-Enhanced CVD (PECVD), for example, uses plasma to energize the precursor gas, allowing the deposition to occur at much lower temperatures.

Process Complexity

The need for vacuum systems, precise temperature and gas flow control, and the handling of volatile precursor materials makes CVD a complex and often expensive process compared to simpler coating methods.

How to Apply This to Your Goal

Choosing the right deposition technique depends entirely on the desired outcome and the constraints of your material.

- If your primary focus is cutting-edge electronics or sensors: CVD is the industry standard for producing the high-purity graphene and other semiconductor films essential for high-performance devices.

- If your primary focus is creating durable, protective coatings: CVD is used to apply ultra-hard ceramic layers onto industrial tools and components, dramatically increasing their wear resistance and lifespan.

- If your primary focus is working with heat-sensitive materials: You should investigate lower-temperature variants like PECVD to deposit high-quality films without damaging the underlying substrate.

Ultimately, chemical vapor deposition is a cornerstone technology that enables the fabrication of advanced materials from the atoms up.

Summary Table:

| Feature | Advantage |

|---|---|

| Film Quality | High purity, uniform, dense layers with excellent crystallization |

| Material Versatility | Deposits metals, non-metals, alloys, and hard ceramics |

| Coating Capability | Conformal, wrap-around coverage for complex 3D objects |

| Primary Limitation | Often requires high temperatures (solved by variants like PECVD) |

Ready to integrate high-purity, uniform coatings into your lab's workflow?

KINTEK specializes in providing the precise lab equipment and consumables needed for advanced processes like Chemical Vapor Deposition. Whether you are developing cutting-edge electronics, creating durable protective coatings, or working with heat-sensitive materials, our solutions are designed to meet the demanding requirements of modern laboratories.

Contact our experts today to discuss how we can support your specific application and help you achieve superior material performance.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is LPCVD advantages and disadvantages? Balancing Film Quality and Thermal Budget

- What are the advantages of physical vapour deposition? Superior, Durable Coatings for Your Components

- What are the factors affecting chemical vapor deposition? Master the Core Parameters for Superior Thin Films

- How is metal deposited on a surface using sputter deposition? A Guide to High-Quality Thin Film Coating

- What does the CVD stand for? A Guide to Chemical Vapor Deposition Technology

- What is an example of a chemical vapor deposition? Discover How CVD Builds Microchips and Solar Panels

- What are the applications of thin film interference? Control Light & Measure with Nanometer Precision

- Is vacuum a requirement for CVD? Understanding Pressure's Role in Film Quality