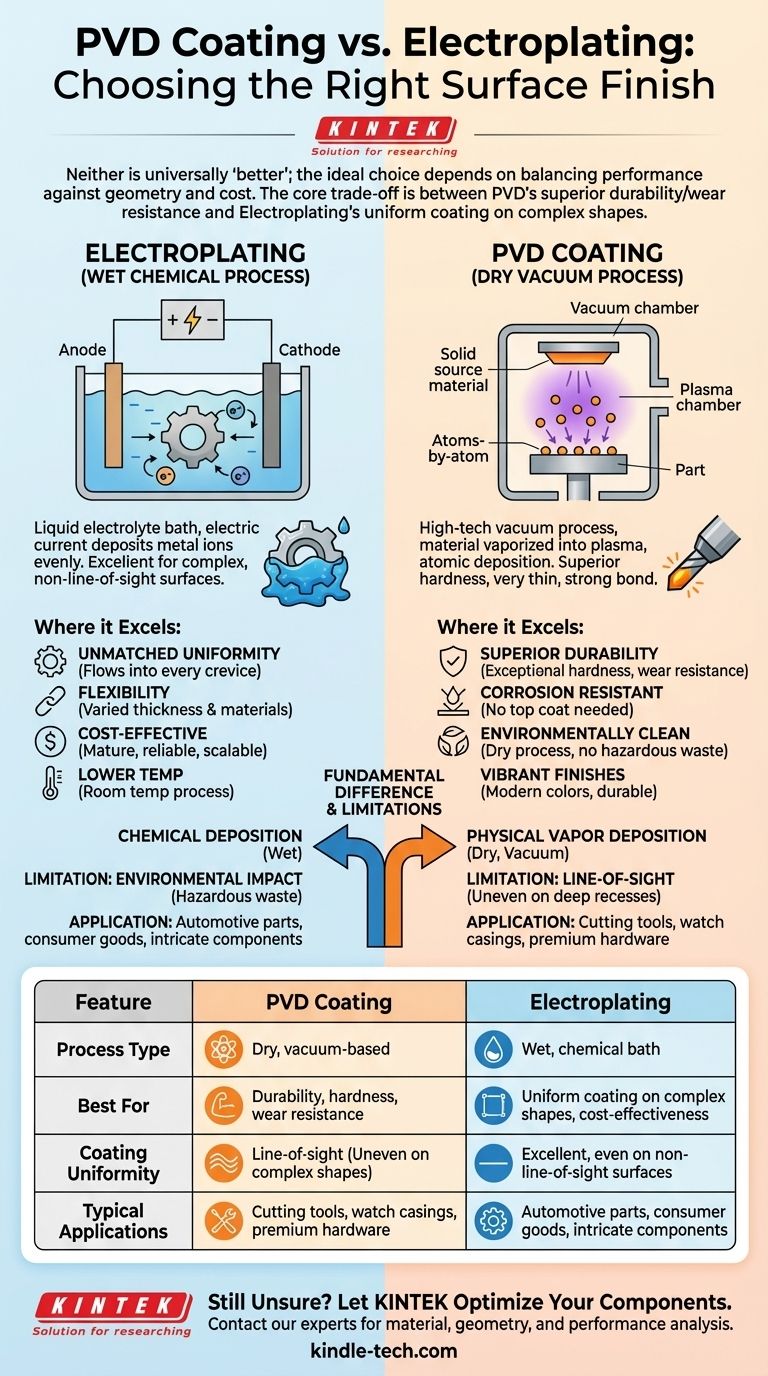

In short, PVD is superior for durability, wear resistance, and hardness, while electroplating is better for achieving a uniform coating on complex shapes and is often more cost-effective. Neither is universally "better"; the ideal choice depends entirely on the specific requirements of your application, balancing performance against geometry and cost.

The core decision between PVD and electroplating is a trade-off between performance and versatility. PVD provides a physically harder and more resilient surface finish, whereas electroplating offers unparalleled ability to coat intricate, non-line-of-sight surfaces uniformly.

What is the Fundamental Difference?

To make an informed choice, you must first understand that these two processes operate on completely different principles.

Electroplating: A "Wet" Chemical Process

Electroplating uses a liquid chemical bath (an electrolyte) and an electric current. The part to be coated is submerged in the bath, and the current causes metal ions from the solution to deposit evenly onto the part's surface.

Think of it as a highly controlled process where electricity persuades metal to chemically bond onto an object's surface.

PVD: A "Dry" Vacuum Process

Physical Vapor Deposition (PVD) is a high-tech vacuum process. Inside a vacuum chamber, a solid source material (like titanium or zirconium) is vaporized into a plasma. This vapor is then deposited, atom by atom, onto the object, forming a very thin, hard, and strongly bonded coating.

This is more like spray painting on an atomic level, occurring in a vacuum to ensure purity and adhesion.

Where PVD Coating Excels: Durability and Performance

For applications where toughness is the primary concern, PVD technology offers significant advantages.

Superior Hardness and Wear Resistance

PVD coatings are exceptionally hard, often forming ceramic or composite layers on the substrate. This results in a finish that is highly resistant to scratches, abrasion, and daily wear and tear.

This is why PVD is the standard for high-performance cutting tools, watch casings, and premium hardware.

Excellent Corrosion and Tarnish Resistance

Unlike many electroplated finishes that require a clear top coat for protection, PVD coatings are inherently resistant to corrosion and tarnishing from UV light, saltwater, and common chemicals. The finish you get is the finish that lasts.

Environmental Advantages

The PVD process is environmentally clean. It's a dry process that doesn't produce the hazardous chemical waste often associated with traditional electroplating, making it a more sustainable choice.

Where Electroplating Holds Its Ground: Versatility and Cost

Despite PVD's performance benefits, the long-established process of electroplating remains the superior choice for many critical applications.

Unmatched Coating Uniformity

Because electroplating is a "wet" process, the liquid electrolyte flows into every crevice and internal channel of a part. This ensures a completely uniform and consistent coating, even on highly complex, non-line-of-sight geometries.

Flexibility in Thickness and Materials

Electroplating offers greater control over the final coating thickness, allowing for very thin to very thick layers as needed. The process has been perfected for a vast range of metals and alloys, offering a wider material palette.

A Mature and Cost-Effective Process

As a technology that has been refined over a century, electroplating is reliable, well-understood, and highly scalable. The equipment and energy requirements are often lower than PVD, making it a more economical solution for many components.

Understanding the Trade-offs and Limitations

True expertise comes from understanding not just the benefits, but also the inherent limitations of each technology.

The Line-of-Sight Problem with PVD

PVD is a line-of-sight process. The vaporized material travels in a straight line, making it very difficult to evenly coat deep recesses, internal bores, or complex three-dimensional shapes without sophisticated and costly part-rotation systems.

The Environmental Impact of Electroplating

Traditional electroplating often uses hazardous materials that require careful and expensive handling and disposal. While modern advancements have improved the process, its environmental footprint remains a significant consideration.

Substrate and Temperature Considerations

PVD processes operate at elevated temperatures (around 500°C). While this is lower than other vapor deposition methods, it can still be high enough to distort or damage heat-sensitive materials. Electroplating is typically performed at or near room temperature.

Making the Right Choice for Your Application

To choose correctly, you must align the process with your primary goal.

- If your primary focus is maximum durability and wear resistance: PVD is the definitive choice for products like tools, firearms, watches, and high-traffic architectural fixtures.

- If your primary focus is coating complex shapes uniformly: Electroplating is superior for parts with internal channels, deep grooves, or intricate geometries where complete coverage is critical.

- If your primary focus is cost-effectiveness for a proven finish: For many standard applications where extreme hardness isn't the key requirement, electroplating remains the more economical and reliable solution.

- If your primary focus is a specific decorative finish: For classic, deep chrome or polished gold, electroplating is the standard. For modern colors like gunmetal, black, rose gold, or bronze, PVD offers a more durable and vibrant finish.

By understanding the core mechanics of each process, you can select the coating that delivers the precise performance, appearance, and value your project demands.

Summary Table:

| Feature | PVD Coating | Electroplating |

|---|---|---|

| Process Type | Dry, vacuum-based | Wet, chemical bath |

| Best For | Durability, hardness, wear resistance | Uniform coating on complex shapes, cost-effectiveness |

| Coating Uniformity | Line-of-sight (can be uneven on complex shapes) | Excellent, even on non-line-of-sight surfaces |

| Typical Applications | Cutting tools, watch casings, premium hardware | Automotive parts, consumer goods, intricate components |

Still Unsure Which Coating is Right for Your Project?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including coating technologies. Our experts can help you analyze your specific requirements for material, geometry, and performance to determine the optimal solution—whether it's a durable PVD coating or a versatile electroplating process.

We help you achieve:

- Enhanced Product Performance: Select the coating that maximizes durability and lifespan.

- Cost-Effective Solutions: Balance performance needs with budget constraints.

- Technical Expertise: Leverage our deep knowledge of material science and coating applications.

Let's optimize your components together. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance