At the heart of any sintering furnace, the most important temperature control is the single-loop intelligent temperature controller. This device acts as the brain of the operation, executing precise heating and cooling cycles that are essential for transforming powdered materials into a solid, durable final product.

The goal of temperature control in a sintering furnace isn't just to reach a high temperature; it's to execute a pre-programmed, multi-stage temperature profile with extreme precision and safety to achieve specific material properties.

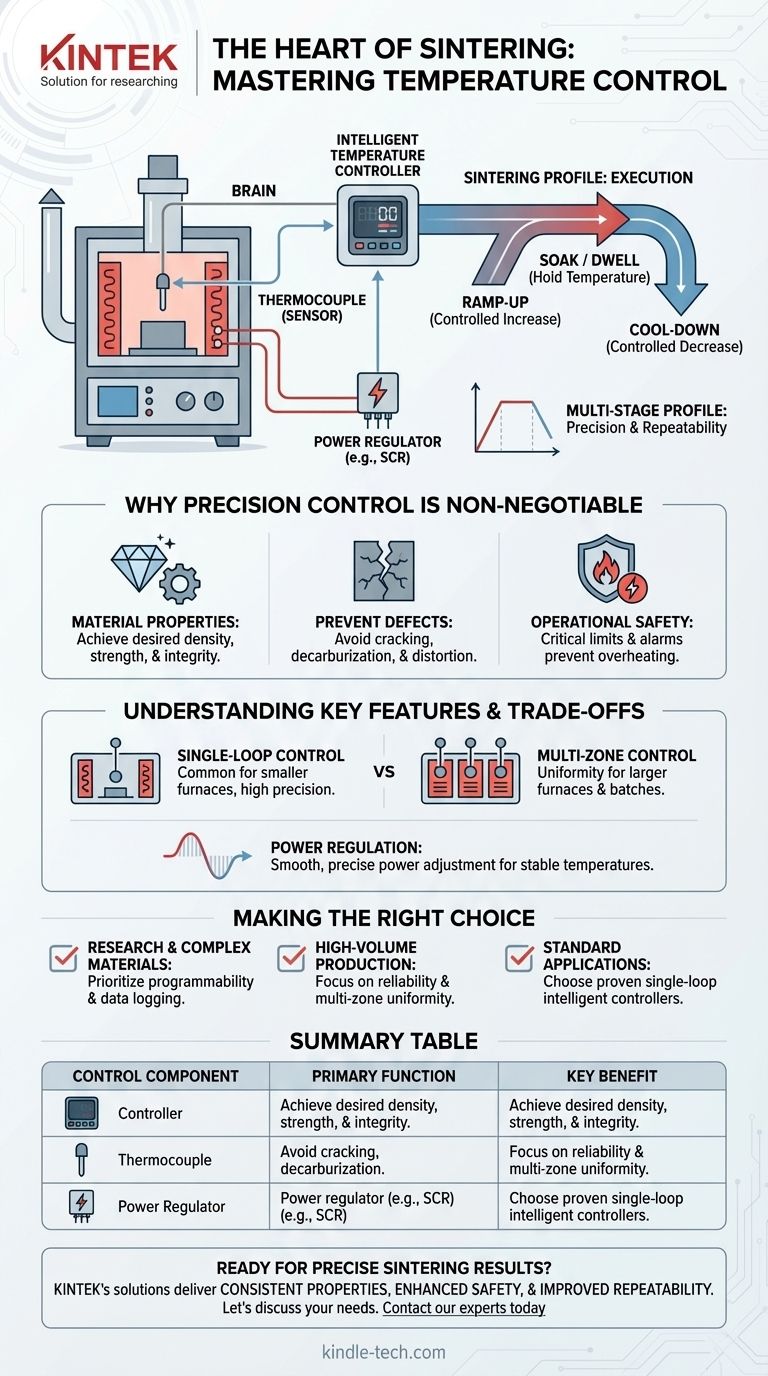

The Core of Sintering: Executing the Temperature Profile

A sintering furnace does not simply turn on and get hot. Its primary function is to follow a meticulously planned thermal recipe, known as a sintering profile, which is critical for the final material's integrity.

What is a Sintering Profile?

A sintering profile consists of several distinct stages:

- Ramp-up: The furnace temperature increases at a controlled rate.

- Soak (or Dwell): The furnace holds a specific high temperature for an extended period.

- Cool-down: The furnace cools at a controlled rate to prevent thermal shock and material defects.

The Role of the Intelligent Temperature Controller

The intelligent temperature controller is the device responsible for managing this entire profile. It continuously compares the actual furnace temperature, measured by a sensor, to the desired temperature setpoint in the program.

Based on this comparison, it adjusts the power sent to the furnace's heating elements to ensure the profile is followed exactly. The "intelligent" aspect refers to its ability to store and execute these complex, multi-stage programs automatically.

The Critical Sensor: The Thermocouple

The controller is only as good as the information it receives. In high-temperature applications like sintering, this information comes from a thermocouple. This robust sensor provides the real-time temperature feedback that the controller needs to make its decisions.

Why Precision Control is Non-Negotiable

In high-temperature material processing, minor deviations in the temperature profile can have major consequences. This makes the quality and reliability of the control system paramount.

Achieving Desired Material Properties

The precise temperatures and durations of the sintering profile directly determine the final properties of the material, such as its density, strength, and structural integrity. This is especially true for advanced materials like zirconia ceramics or diamond tools.

Preventing Material Defects

Improper temperature control can ruin the product. For example, poor control can lead to decarburization (the loss of carbon from the material's surface) or cracking caused by cooling too quickly.

Ensuring Operational Safety

Sintering furnaces operate at extraordinarily high temperatures for long periods, drawing significant electrical current. A reliable temperature control system with safety limits and alarms is the most important feature for preventing overheating, equipment failure, and hazardous conditions.

Understanding Key Features and Trade-offs

When evaluating a furnace's control system, it's important to look beyond the basics and understand the features that impact performance and scalability.

Single-Loop vs. Multi-Zone Control

The term "single-loop" means the controller is managing one sensor and one set of heating elements, treating the furnace as a single thermal zone. This is common and effective for smaller furnaces.

Larger furnaces often use multi-zone controllers to manage several thermocouples and heating element groups independently, ensuring a more uniform temperature throughout the entire chamber.

The Importance of Power Regulation

The temperature controller itself does not handle the high amperage required to power the furnace. It sends a low-voltage signal to a separate power regulator (like an SCR), which modulates the high-power electricity flowing to the heating elements. The quality of this component is also critical for precise control.

Making the Right Choice for Your Application

The ideal control system depends entirely on your specific material and production goals.

- If your primary focus is research or complex materials: Prioritize a highly programmable controller with data logging capabilities to analyze and refine your sintering profiles.

- If your primary focus is high-volume production: Emphasize reliability, robust safety interlocks, and consider multi-zone control for ensuring uniformity in larger batches.

- If your primary focus is a standard application: A proven, reliable single-loop intelligent controller is the industry standard and provides the necessary precision for materials like zirconia and ceramic powders.

Ultimately, the right temperature control system is what transforms a simple high-temperature oven into a precise and repeatable materials processing tool.

Summary Table:

| Control Component | Primary Function | Key Benefit |

|---|---|---|

| Intelligent Temperature Controller | Executes multi-stage sintering profiles (ramp-up, soak, cool-down) | Ensures precise, repeatable thermal cycles for consistent material properties |

| Thermocouple | Provides real-time furnace temperature feedback to the controller | Enables accurate control and prevents defects from temperature deviations |

| Power Regulator (e.g., SCR) | Modulates high-power electricity to heating elements based on controller signals | Allows for smooth and precise power adjustment for stable temperatures |

Ready to achieve precise and reliable sintering results?

The right temperature control system is the key to transforming powdered materials into high-performance components. Whether your focus is advanced research, high-volume production, or standard applications, KINTEK's expertise in lab equipment ensures you have the precise thermal control needed for success.

We specialize in providing sintering solutions that deliver:

- Consistent Material Properties: Achieve the exact density, strength, and integrity your materials require.

- Enhanced Operational Safety: Rely on robust systems with safety limits to protect your lab and products.

- Improved Process Repeatability: Automate complex sintering profiles for reliable results batch after batch.

Let's discuss your specific sintering needs. Contact our experts today to find the ideal furnace and control system for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the main advantages of vacuum sintering? Achieve Superior Purity and Performance

- What is the function of a VHPS system in CoCrFeNiMn alloys? Achieve Near-Theoretical Density and High Purity