The primary advantages of a two-plate mold are its simplicity, lower cost, and operational reliability. Because it is constructed from only two main plates that separate on a single plane, it has fewer components, is less expensive to manufacture, and is easier to operate and maintain than more complex mold designs.

A two-plate mold's simple design is its greatest strength, directly translating to lower initial costs and more straightforward, reliable production runs. However, this simplicity also imposes fundamental design limitations, particularly regarding where the plastic can be injected into the part.

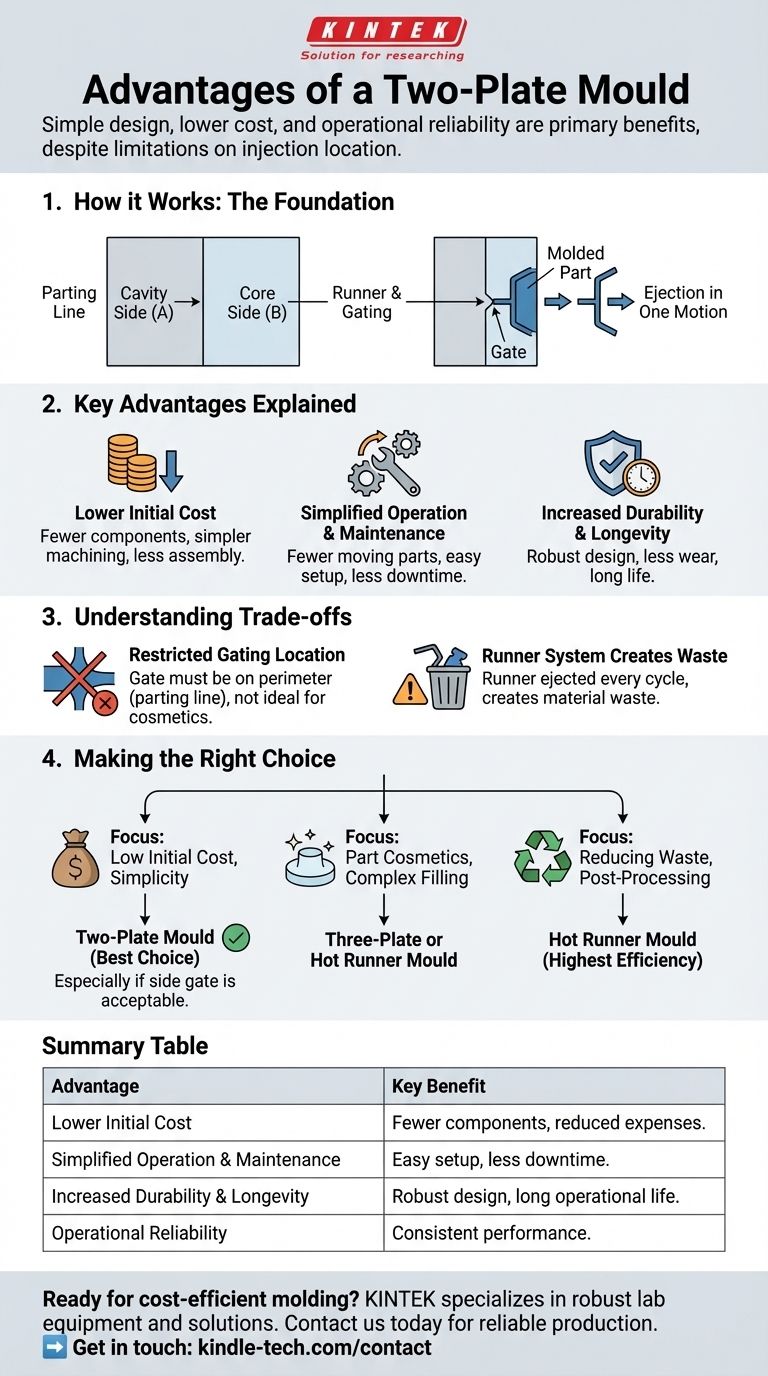

The Foundation: How a Two-Plate Mold Works

To understand the advantages, it's crucial to grasp the mold's basic structure. It consists of two primary halves: the cavity side (A-side) and the core side (B-side).

A Single Parting Line

The defining feature is its single parting line. This is the one surface where the two mold halves separate to eject the finished plastic part.

The Runner and Gating System

The runner—the channel that transports molten plastic from the molding machine's nozzle to the part—is machined into the surface of this same parting line. The part is filled via a gate located directly on its edge or perimeter.

Ejection in One Motion

When the mold opens, both the molded part and the solidified runner system are held on the core side. An ejector system then pushes both out simultaneously as a single unit.

Key Advantages Explained

The simple "part-and-runner" ejection design is the source of all its primary benefits.

Lower Initial Cost

A two-plate mold is the most cost-effective mold design. Its construction requires fewer components, simpler machining processes, and less assembly time compared to three-plate or hot runner molds.

Simplified Operation and Maintenance

With fewer moving parts, there are fewer potential points of failure. This makes the mold easier to set up in a press, simpler to run in production, and faster to troubleshoot and maintain, resulting in less downtime.

Increased Durability and Longevity

Simplicity equals robustness. The straightforward mechanical action of a two-plate mold leads to less wear and tear over its operational life, contributing to its reputation for longevity.

Understanding the Trade-offs and Limitations

The simplicity that provides these benefits also creates significant constraints. Acknowledging these trade-offs is critical for making an informed decision.

Gating Location is Restricted

This is the most significant disadvantage. The gate must be located on the part's perimeter, right at the parting line. This is often not the ideal location for cosmetic appearance or for ensuring the part fills evenly.

Runner System Creates Waste

The plastic in the runner system is ejected with the part in every cycle. This runner must then be trimmed off in a secondary operation, creating material waste and adding labor or automation costs.

Not Ideal for Certain Geometries

If a part requires a gate in its center for structural or cosmetic reasons (a "pin-point" gate), a two-plate mold cannot achieve this. It is also poorly suited for multi-cavity layouts where parts are arrayed far from the central sprue.

Making the Right Choice for Your Project

Choosing between a two-plate and a more complex mold depends entirely on your project's specific priorities.

- If your primary focus is minimizing initial cost and maximizing simplicity: A two-plate mold is almost always the superior choice, especially for parts where a side gate is functionally and cosmetically acceptable.

- If your primary focus is part cosmetics or complex mold filling: You will likely need a three-plate or hot runner mold to control the gate location and avoid blemishes on visible surfaces.

- If your primary focus is reducing material waste and post-processing: A hot runner mold, which eliminates the runner entirely, is the most efficient option, though it carries a much higher initial cost.

Understanding these fundamental trade-offs empowers you to select the most effective and economical molding strategy for your specific part.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Lower Initial Cost | Fewer components and simpler machining reduce manufacturing expenses. |

| Simplified Operation & Maintenance | Easy setup, fewer failure points, and less downtime. |

| Increased Durability & Longevity | Robust design with straightforward mechanics ensures long operational life. |

| Operational Reliability | Consistent performance with fewer moving parts and simpler mechanical action. |

Ready to leverage the simplicity and cost-efficiency of a two-plate mold for your next project?

At KINTEK, we specialize in providing robust lab equipment and consumables, including solutions for your plastic molding and material testing needs. Our expertise ensures you get the right equipment for reliable, cost-effective production.

Contact us today to discuss how our solutions can enhance your lab's efficiency and deliver superior results. ➡️ Get in touch via our contact form

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Cylindrical Press Mold for Lab Applications

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

People Also Ask

- What is the function of a graphite mold during the vacuum hot pressing sintering process? Optimize Composite Performance

- What is mold maintenance? A Proactive Strategy to Maximize Tool Lifespan and Quality

- What is the function of a stainless steel pressure mold in solid-state battery testing? Optimize Ionic Conductivity

- What are the 5 steps of injection molding? A Guide to Efficient, High-Quality Production

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- What function does a graphite mold serve during the hot-press sintering of fluoride ceramics? Enhance Densification

- Why are high-strength graphite molds required during the vacuum hot pressing process for TiAl/Ti6Al4V composites?

- What roles do high-purity graphite molds play during VHP of SiC/Al? Enhance Your Composite Material Quality