For large-scale industrial production, the definitive choice is a rotary tablet press. These machines are specifically engineered for high-volume output, consistency, and automation, making them the standard for pharmaceutical and industrial manufacturing. While they are electrically powered, it is their multi-station, continuous-motion design that truly sets them apart.

The core decision is not simply about choosing an "electric" press, but understanding the fundamental mechanical difference. Large-scale production demands a rotary press for its continuous, multi-station operation, while small-scale and R&D work is best suited for a single-punch press.

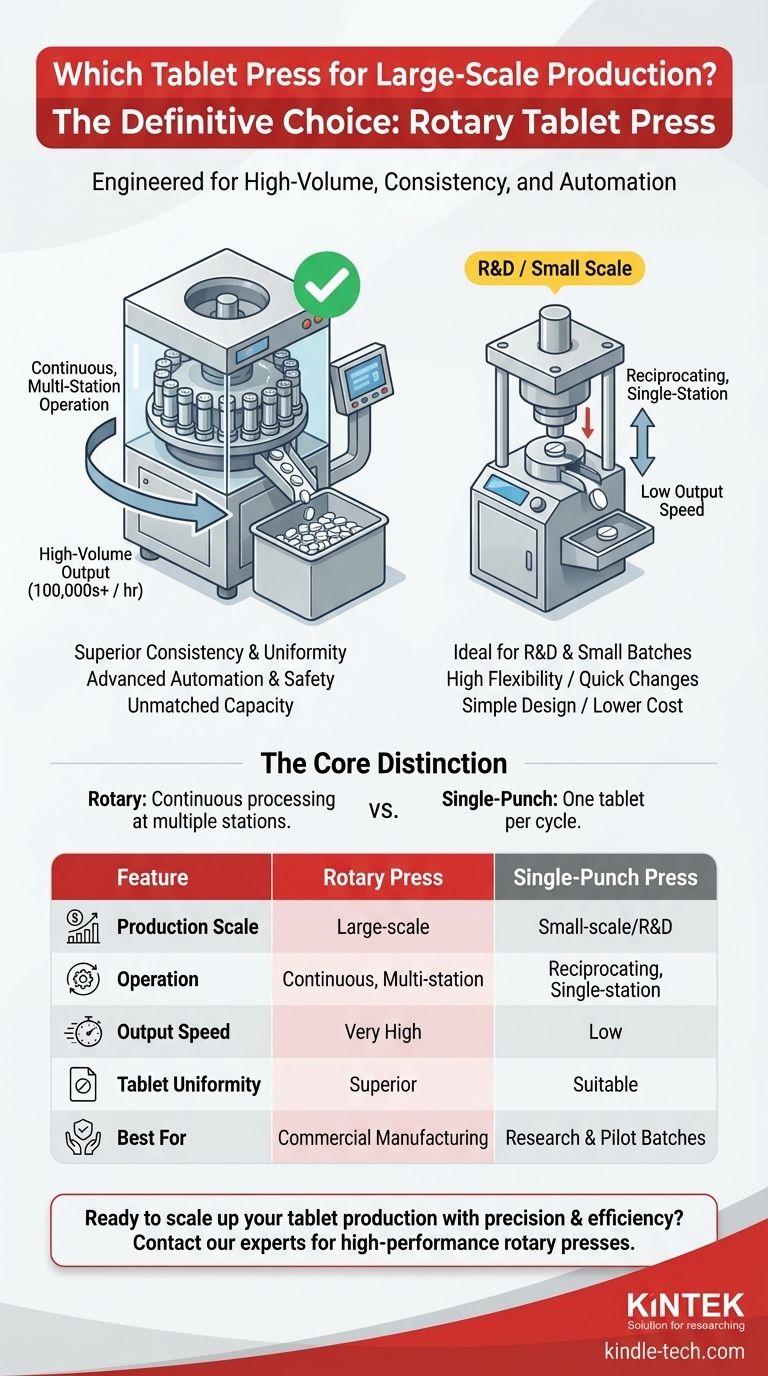

The Core Distinction: Rotary vs. Single-Punch

The term "tablet press" covers two fundamentally different types of machines, each designed for a specific scale of operation. Understanding this distinction is critical.

How a Rotary Press Works (Continuous Motion)

A rotary press features a large, rotating turret that holds numerous sets of dies and punches, often referred to as "stations."

As the turret spins, the dies are filled with powder, and the powder is then compressed into tablets simultaneously at multiple stations.

This continuous, parallel processing is the key to its immense output, allowing it to produce hundreds of thousands, or even millions, of tablets per hour.

How a Single-Punch Press Works (Reciprocating Motion)

A single-punch press (or eccentric press) has only one station, consisting of a single die and a pair of upper and lower punches.

The machine works through a reciprocating up-and-down motion, compressing one tablet at a time per cycle.

This design is simpler and slower, making it unsuitable for mass production but ideal for careful formulation development and small test batches.

Why Rotary Presses Excel at Scale

The design of a rotary press directly addresses the primary demands of large-scale manufacturing: speed, consistency, and efficiency.

Unmatched Production Capacity

The most significant advantage is sheer volume. With dozens of stations operating simultaneously, a rotary press can achieve production rates that are orders of magnitude higher than a single-punch press.

This makes it the only viable option for commercial-level manufacturing where output is measured in tablets per minute or hour.

Superior Consistency and Uniformity

The continuous and highly controlled mechanics of a modern rotary press result in exceptional uniformity in tablet weight, thickness, and hardness.

This consistency is crucial for quality control, ensuring that every tablet meets precise specifications, a non-negotiable requirement in regulated industries like pharmaceuticals.

Automation and Safety

Modern electric rotary presses are highly automated systems. They incorporate advanced safety features, automatic weight control, and rejection systems for out-of-spec tablets.

This level of automation reduces the need for manual intervention, minimizes human error, and improves overall process efficiency and safety.

Understanding the Trade-offs

While rotary presses are the solution for scale, single-punch presses still play a crucial, distinct role in the industry.

The Purpose of Single-Punch Presses

These presses are the workhorses of research and development (R&D) and pilot-scale batches.

Their simple design allows for quick tooling changes and precise adjustments, making them perfect for testing new formulas, studying material properties, and producing small quantities for clinical trials.

Higher Initial Investment

A high-capacity rotary press represents a significant capital investment. The cost is substantially higher than that of a single-punch press, reflecting its complexity, size, and advanced features.

Complexity in Operation and Maintenance

The multi-station design and automation features that enable high output also mean that rotary presses are more complex to set up, operate, and maintain. They require skilled technicians for tool setup (tooling), calibration, and routine maintenance.

Making the Right Choice for Your Goal

Selecting the right press is entirely dependent on your production objective.

- If your primary focus is large-scale commercial manufacturing: The rotary tablet press is the only suitable choice for its high capacity, consistency, and automation.

- If your primary focus is research, formulation development, or small pilot batches: The single-punch press provides the necessary control, flexibility, and cost-effectiveness for this purpose.

Ultimately, choosing the correct tablet press is about matching the machine's core design capabilities to the specific scale of your operation.

Summary Table:

| Feature | Rotary Press | Single-Punch Press |

|---|---|---|

| Production Scale | Large-scale (100,000s+/hr) | Small-scale/R&D |

| Operation | Continuous, multi-station | Reciprocating, single-station |

| Output Speed | Very High | Low |

| Tablet Uniformity | Superior | Suitable for development |

| Best For | Commercial manufacturing | Research & pilot batches |

Ready to scale up your tablet production with precision and efficiency? KINTEK specializes in high-performance lab equipment, including robust rotary tablet presses designed for large-scale industrial needs. Our solutions ensure consistent quality, automation, and reliability for your manufacturing process. Contact our experts today to find the perfect press for your production goals!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- How does a flat die pellet mill work? A Complete Guide to Small-Scale Pellet Production

- What is a tablet punch? The Precision Tool Shaping Your Tablet Manufacturing

- What are the different types of pelletizers? A Guide to Choosing the Right Machine for Your Material

- What size are pellet mill die sizes? Master the L/D Ratio for Perfect Pellets

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- What are the steps of tablet production by direct compression? Streamline Your Manufacturing Process

- What is a press tab pill? The Complete Guide to Pressed Tablets