It's true, the cost of a ceramic crown can be surprising. The price isn't for a simple tooth covering, but for a custom-engineered medical device that blends advanced materials, digital technology, and human artistry. The high cost reflects the significant investment in expertise and equipment required to create a restoration that is both durable and indistinguishable from a natural tooth.

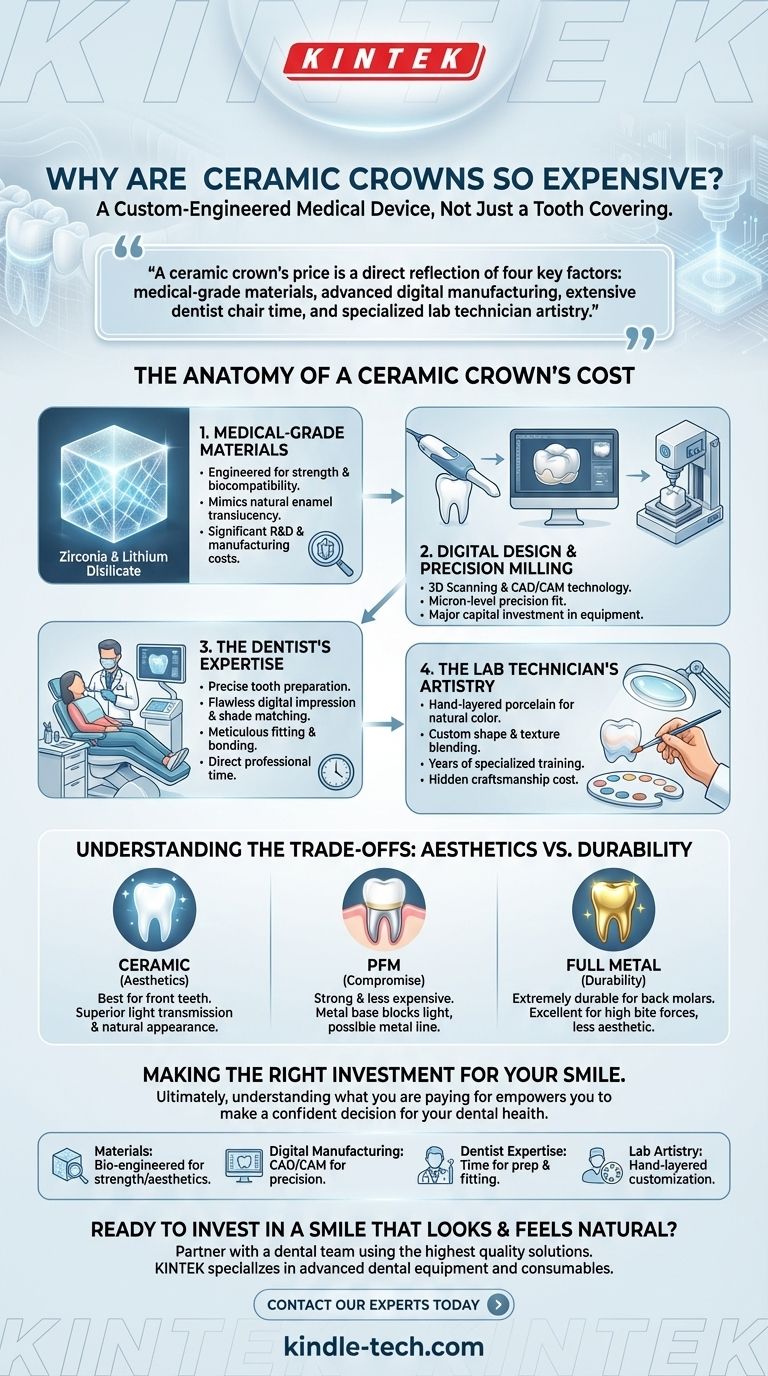

A ceramic crown's price is a direct reflection of four key factors: the cost of medical-grade materials, the advanced digital manufacturing technology, the extensive chair time with your dentist, and the specialized skill of the dental lab technician who crafts it.

The Anatomy of a Ceramic Crown's Cost

To understand the price, you must understand the process. A dental crown is not a mass-produced item; it is a bespoke solution for a unique clinical need.

The Material Itself: Medical-Grade Ceramics

The term "ceramic" can be misleading. This isn't pottery-grade clay; it's a highly advanced biomaterial, often zirconia or lithium disilicate.

These materials are engineered for incredible strength, biocompatibility with your body's tissues, and optical properties that mimic the translucency of natural tooth enamel. The research, development, and manufacturing of these materials carry a significant cost.

The Technology: Digital Design and Precision Milling

Modern dentistry has moved far beyond physical impressions. The process often involves CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology.

This starts with a high-resolution 3D scan of your tooth. A technician then uses sophisticated software to digitally design a crown with a perfect fit, down to the micron. This digital file is sent to a robotic milling machine that carves the crown from a solid block of ceramic. This equipment represents a major capital investment for the dental practice or lab.

The Human Factor: The Dentist's Expertise

A significant portion of the cost is for the dentist's direct time and clinical judgment.

This includes precisely preparing the tooth to support a crown, taking flawless digital scans, ensuring perfect shade matching, and meticulously fitting and bonding the final crown. Each of these steps requires immense skill and can be time-consuming to perform correctly.

The Artistry: The Dental Laboratory Technician

This is the hidden cost many people don't see. A highly skilled dental technician is an artist.

After the crown is milled, the technician often applies layers of porcelain by hand to create subtle color variations and a natural-looking finish. They customize the shape and texture to ensure it blends seamlessly with your smile. This level of craftsmanship requires years of specialized training.

Understanding the Trade-offs

The high cost of a ceramic crown is best understood when compared to the alternatives. You are paying for a specific set of benefits.

The Gold Standard: Aesthetics

For front teeth, nothing matches the natural appearance of a full ceramic crown. Its ability to let light pass through it is what makes it look like a real tooth, avoiding the opaque look of other materials.

The Compromise: Porcelain-Fused-to-Metal (PFM)

PFM crowns have a metal base with porcelain layered on top. They are strong and less expensive but have drawbacks. The metal base blocks light, making them look less natural. Over time, a dark metal line can become visible at the gumline.

The Workhorse: Full Metal Crowns

Gold or metal alloy crowns are extremely durable and gentle on opposing teeth. They are an excellent choice for back molars where biting forces are high and aesthetics are not a concern. Their cost is often comparable to or less than ceramic, depending on the price of gold.

Making the Right Investment for Your Smile

Choosing a crown is a long-term investment in your health, function, and confidence. The "best" choice depends entirely on your specific goal for the tooth in question.

- If your primary focus is aesthetics for a visible tooth: An all-ceramic crown is the superior choice, and its higher cost is justified by the lifelike result.

- If your primary focus is maximum durability on a back molar: A gold crown remains an exceptional, long-lasting option that should not be overlooked.

- If your primary focus is a balance of budget and appearance: A PFM crown offers a reliable, tooth-colored solution that is more economical than all-ceramic options.

Ultimately, understanding what you are paying for empowers you to make a confident decision for your dental health.

Summary Table:

| Cost Factor | Key Details |

|---|---|

| Medical-Grade Materials | High-strength zirconia or lithium disilicate, engineered for biocompatibility and natural aesthetics. |

| Digital Manufacturing | Investment in CAD/CAM technology for 3D scanning, digital design, and precision milling. |

| Dentist's Expertise | Chair time for tooth preparation, shade matching, and meticulous fitting and bonding. |

| Lab Technician Artistry | Hand-layered porcelain and customization for a seamless, natural-looking finish. |

Ready to invest in a smile that looks and feels natural?

Understanding the value behind a ceramic crown is the first step. The next is partnering with a dental team that has access to the highest quality materials and technology. KINTEK specializes in providing dental laboratories with the advanced equipment and consumables needed to create precise, durable, and aesthetically perfect restorations.

If you're a dental professional seeking to elevate your practice's capabilities, contact our experts today to learn how our solutions can support your commitment to excellence in patient care.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the mode of failure most often associated with ceramic dental implants? Understanding Fracture Risk

- What is the temperature of zirconia? Mastering the Sintering Cycle for Maximum Strength

- What is the strongest type of zirconia? A Guide to Choosing the Right Dental Zirconia

- Can ceramic crowns be repaired? A Dentist's Guide to Assessing the Damage

- What is a porcelain furnace used for in dentistry? Precision Crafting for Lifelike Dental Restorations

- What is the average lifespan of a dental restoration? Maximize Your Investment with the Right Material

- What is the difference between zirconia and ceramic? A Guide to Choosing the Right Dental Crown

- Do ceramic crowns look natural? Achieve a Seamless, Natural-Looking Smile