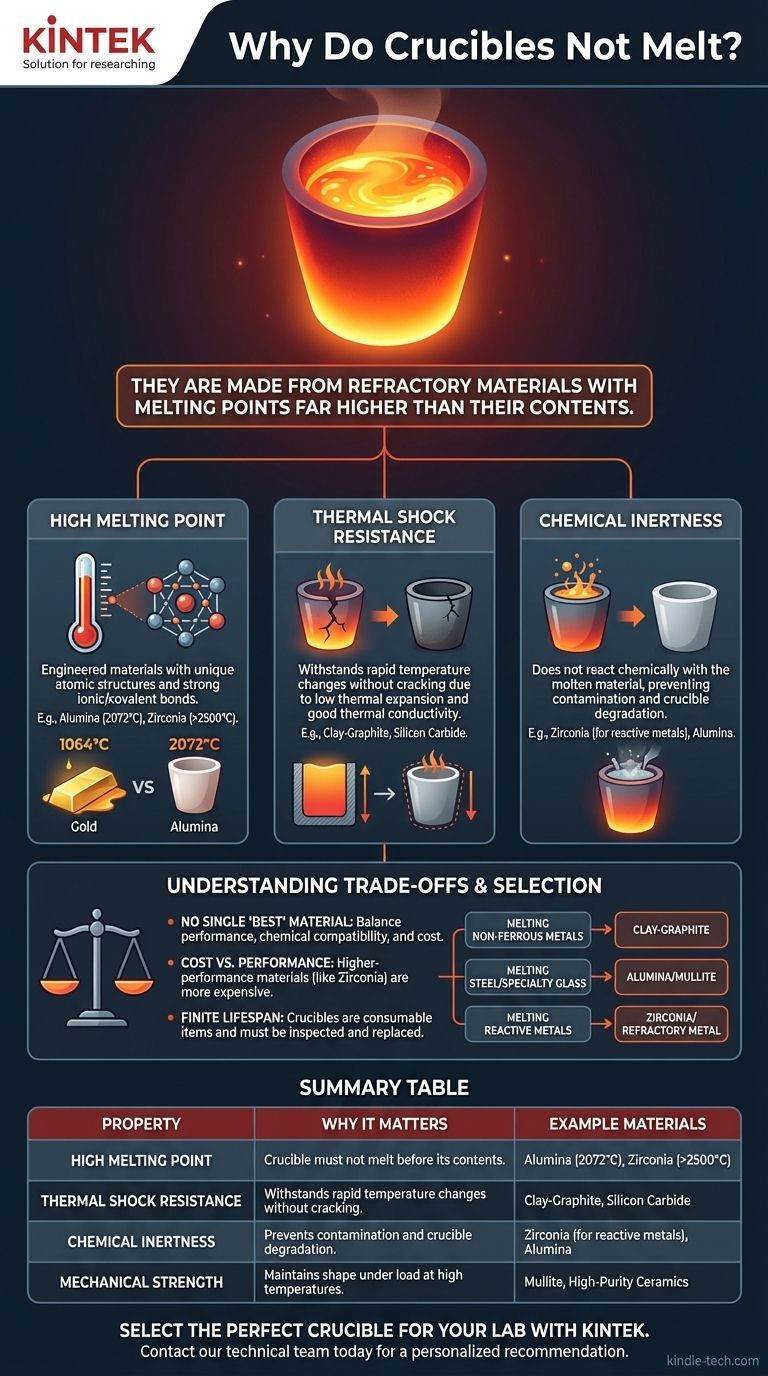

In short, crucibles do not melt because they are constructed from specialized materials, known as refractory materials, whose melting points are significantly higher than the substances they are intended to hold. The material for a crucible is always selected to have a melting temperature far above the working temperature required for the specific metal, glass, or other compound being melted.

The simple answer is an exceptionally high melting point. The complete answer is that crucibles are engineered from specific refractory materials chosen for a combination of thermal resilience, chemical inertness, and structural strength at extreme temperatures.

The Science of Refractory Materials

To understand a crucible, you must first understand the class of materials it belongs to. Crucibles are not made from ordinary ceramics or metals; they are made from refractory materials.

What is a Refractory Material?

A refractory material is any substance, typically non-metallic, that can maintain its physical and chemical integrity at very high temperatures. Their primary purpose is to contain heat and provide structural support in high-temperature environments like furnaces, kilns, and foundries.

The Critical Role of High Melting Point

The most obvious requirement is that a crucible must not melt before its contents. Refractory materials have exceptionally high melting points due to their unique atomic structure.

For example, alumina (aluminum oxide), a common crucible material, melts at approximately 2072°C (3762°F). This makes it suitable for melting metals like gold (1064°C) or even iron (1538°C) with a significant margin of safety.

Atomic Bonds and Crystal Structure

The immense heat resistance of these materials comes from their internal structure. The atoms in refractory ceramics like alumina or zirconia are held together by extremely strong ionic or covalent bonds.

Breaking these powerful bonds requires a tremendous amount of thermal energy, which translates directly into a very high melting point.

Beyond Melting Point: Essential Crucible Properties

A high melting point is necessary, but it is not sufficient. Several other properties are critical for a crucible to function safely and effectively.

Thermal Shock Resistance

A crucible must withstand rapid and extreme temperature changes without cracking. This property is known as thermal shock resistance.

Materials expand when heated and contract when cooled. If this happens too quickly or unevenly, internal stresses can build up and shatter the material. Crucibles are designed with low thermal expansion and good thermal conductivity to manage these stresses.

Chemical Inertness

The crucible must not react chemically with the molten material it contains. This is called chemical inertness or non-reactivity.

If a reaction occurs, it can contaminate the substance being melted and will also degrade and destroy the crucible itself. The choice of crucible material often depends on the chemical properties of the metal being melted.

Mechanical Strength at Temperature

A material can become soft and deform long before it reaches its melting point. A useful crucible must retain its shape and rigidity even when glowing hot and filled with heavy, molten metal.

This property, known as hot strength or creep resistance, ensures the crucible doesn't sag, bend, or fail under load at operating temperature.

Understanding the Trade-offs

There is no single "perfect" crucible. The selection of a crucible is always a balance of performance requirements, chemical compatibility, and cost.

No Single "Best" Material

An alumina crucible is excellent for many applications but will react with certain elements. A graphite crucible has outstanding thermal shock resistance but can be consumed in an oxygen-rich atmosphere at high temperatures.

Each material represents a specific set of compromises.

Cost vs. Performance

Higher-performance materials command a higher price. A simple clay-graphite crucible is relatively inexpensive, while a high-purity zirconia crucible, needed for extremely high temperatures or reactive metals, can be significantly more costly.

The Finite Lifespan of a Crucible

Crucibles are consumable items. Even when used correctly, the repeated stress of thermal cycling and minor chemical interactions will eventually cause them to degrade. They must be inspected for cracks and erosion before each use and replaced periodically.

Selecting the Right Crucible for Your Task

Your choice depends entirely on the material you are melting and the temperature you need to achieve.

- If your primary focus is melting common non-ferrous metals like aluminum or brass: A clay-graphite crucible offers the best balance of performance, durability, and cost.

- If you are working with high-temperature steel alloys or specialty glass: An alumina or mullite crucible is necessary for its higher temperature rating and chemical stability.

- If you are melting highly reactive metals like titanium or exotic alloys: A specialized zirconia, yttria, or even a refractory metal crucible (like tungsten) is required, despite its high cost.

Understanding these core material properties empowers you to select the precise tool needed to control heat safely and effectively.

Summary Table:

| Property | Why It Matters | Example Materials |

|---|---|---|

| High Melting Point | Crucible must not melt before its contents. | Alumina (2072°C), Zirconia (>2500°C) |

| Thermal Shock Resistance | Withstands rapid temperature changes without cracking. | Clay-Graphite, Silicon Carbide |

| Chemical Inertness | Prevents contamination and crucible degradation. | Zirconia (for reactive metals), Alumina |

| Mechanical Strength | Maintains shape under load at high temperatures. | Mullite, High-Purity Ceramics |

Select the Perfect Crucible for Your Lab

Choosing the right crucible is critical for the safety and success of your high-temperature applications. The wrong material can lead to contamination, failed experiments, or even dangerous equipment failure.

KINTEK is your trusted partner in laboratory equipment. We specialize in providing the precise crucibles and lab consumables you need, from durable clay-graphite for general use to high-purity alumina and zirconia for the most demanding environments.

Let our experts help you:

- Identify the ideal material for your specific metal, alloy, or compound.

- Ensure operational safety and prevent costly contamination.

- Optimize your process with consumables designed for performance and longevity.

Don't leave your results to chance. Contact our technical team today for a personalized recommendation and get the right tool for the job.

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- How many types of crucibles are there? Choose the Right Material for Your High-Temperature Work

- Why are zirconia crucibles preferred for high-temperature Ni3Al melting? Ensure Purity with Specialized Refractories

- Can you melt copper in a ceramic crucible? Yes, with the right crucible choice.

- What is the best crucible for melting? Choose the Right Crucible for Your Material and Process

- What role does an Alumina Crucible play in the high-temperature solid-state synthesis of Na3OBr? Ensure Sample Purity

- Why are alumina crucibles selected as containers for liquid lead corrosion experiments? Ensure Pure Experimental Data

- How long does a crucible last? Maximize Lifespan with Proper Material & Handling

- What crucible is best for melting gold? Choose the Right Tool for a Clean, Efficient Melt