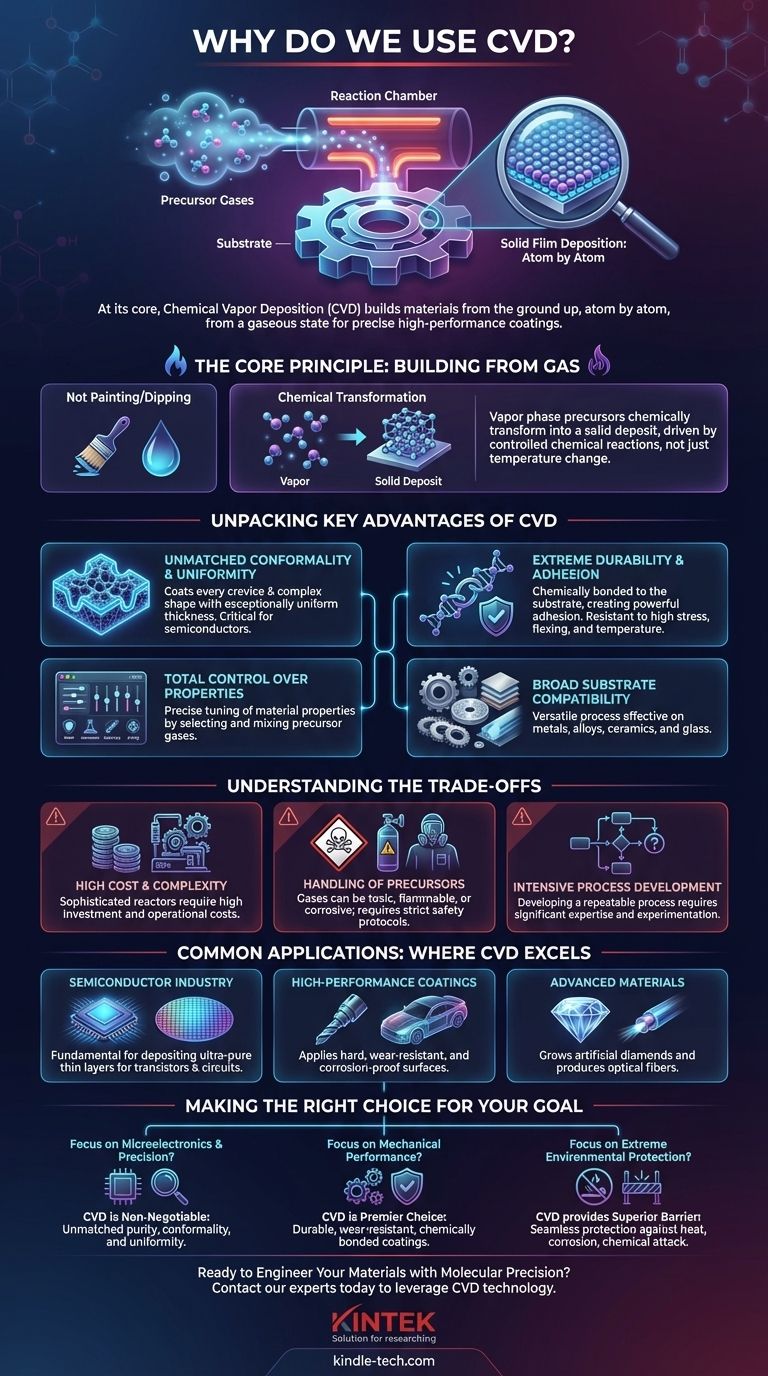

At its core, Chemical Vapor Deposition (CVD) is used because it provides an exceptionally precise way to create high-performance thin films and coatings on a substrate. The process allows for the construction of materials, atom by atom, from a gaseous state. This results in coatings that are incredibly pure, uniform, durable, and can be applied to even the most complex and intricate surfaces.

The true power of CVD is its ability to build materials from the ground up using chemical reactions. This fundamental difference from physical coating methods gives engineers unparalleled control over a material's final properties, from its wear resistance to its electrical conductivity.

The Core Principle: Building Materials from Gas

Chemical Vapor Deposition is not like painting or dipping an object. Instead of applying a pre-made liquid or powder, CVD introduces precursor gases into a reaction chamber containing the object (substrate) you wish to coat.

A Chemical Transformation

These gases react or decompose on the hot surface of the substrate, leaving behind a solid material. The "vapor" phase precursors chemically transform into a solid "deposit."

This process is more like frost forming on a cold window—a gas (water vapor) turns directly into a solid (ice)—but it is driven by controlled chemical reactions rather than just temperature change. This atomic-level deposition is the source of all of CVD's major advantages.

Unpacking the Key Advantages of CVD

The reason CVD is so prevalent in high-tech industries stems from a few key capabilities that are difficult or impossible to achieve with other methods.

Unmatched Conformality and Uniformity

Because the precursor gas can flow into every crevice of a substrate, the resulting solid film is perfectly conformal. It coats internal channels, sharp corners, and complex 3D shapes with a layer of exceptionally uniform thickness.

This is absolutely critical in the semiconductor industry, where microscopic electronic components require perfectly even layers to function correctly.

Extreme Durability and Adhesion

A CVD coating isn't just "stuck on" the surface; it is chemically bonded to it. This creates a powerful bond between the coating and the substrate.

As a result, CVD coatings are highly durable and remain intact even in high-stress environments involving flexing, bending, or extreme temperature variations.

Total Control Over Material Properties

By carefully selecting and mixing the precursor gases, engineers can tune the exact properties of the final deposited material.

This allows for the creation of films optimized for specific functions, such as:

- Wear Resistance: For cutting tools and engine parts.

- Corrosion Resistance: For components in harsh chemical environments.

- High Lubricity: Creating low-friction surfaces.

- High Purity: Essential for semiconductors and optical fibers.

- Chemical Inertness: For medical implants and protective barriers.

Broad Substrate Compatibility

CVD is a highly versatile process that is not limited to one type of base material. It is routinely used to coat a wide variety of substrates, including metals, specialized alloys, ceramics, and even glass.

Understanding the Trade-offs

No process is perfect, and choosing CVD means accepting certain complexities. Understanding these trade-offs is key to making an informed decision.

High Initial Cost and Complexity

CVD reactors are sophisticated pieces of equipment that require high temperatures, vacuum systems, and precise gas control. This makes the initial investment and operational costs higher than simpler coating methods like electroplating or painting.

Handling of Precursor Materials

The precursor gases used in CVD can be toxic, flammable, or corrosive. The process requires stringent safety protocols and specialized handling infrastructure, which adds to the overall complexity and cost.

Process Development Can Be Intensive

CVD is not a "one-size-fits-all" solution. Developing a stable and repeatable process for a new application requires significant expertise and experimentation to optimize the temperature, pressure, gas flow rates, and chemistry.

Common Applications: Where CVD Excels

CVD's unique benefits make it the go-to process in several demanding fields.

In the Semiconductor Industry

CVD is fundamental to modern electronics. It is used to deposit the ultra-pure, uniform, and thin layers of silicon, silicon dioxide, and other materials that form the transistors and circuits inside microchips.

For High-Performance Coatings

The process is used to apply hard coatings to machine tools, increasing their lifespan and performance. It also creates wear-resistant surfaces on automotive parts and corrosion-proof barriers on chemical processing equipment.

In Advanced Materials

CVD's versatility extends beyond simple coatings. It is one of the primary methods used to grow high-purity artificial diamonds for industrial and electronic applications, as well as the core material for optical fibers used in global telecommunications.

Making the Right Choice for Your Goal

When deciding if CVD is the right process, consider the primary engineering problem you are trying to solve.

- If your primary focus is microelectronics and precision: CVD is often non-negotiable due to its unmatched ability to create pure, conformal, and uniform thin films at a microscopic scale.

- If your primary focus is enhancing mechanical performance: CVD is the premier choice for creating durable, wear-resistant, or low-friction coatings that are chemically bonded to tools and components.

- If your primary focus is extreme environmental protection: CVD provides a superior, seamless barrier against high temperatures, corrosion, and chemical attack.

Ultimately, CVD is the process of choice when you need to engineer a material's surface with molecular-level precision.

Summary Table:

| Key Advantage | Why It Matters |

|---|---|

| Conformal & Uniform Coating | Ensures even coverage on complex 3D shapes and microscopic features. |

| Exceptional Durability & Adhesion | Creates a strong chemical bond for coatings that last in high-stress environments. |

| Tailored Material Properties | Allows precise control over characteristics like wear resistance and conductivity. |

| Broad Substrate Compatibility | Effective on a wide range of materials including metals, ceramics, and glass. |

Ready to Engineer Your Materials with Molecular Precision?

If your project demands ultra-pure, uniform, and durable thin films, the advanced capabilities of Chemical Vapor Deposition (CVD) are essential. KINTEK specializes in providing the high-performance lab equipment and expert support needed to leverage CVD technology for your most challenging applications, from semiconductor manufacturing to creating wear-resistant coatings.

Contact our experts today to discuss how our solutions can help you achieve superior results.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How are thin films manufactured? A Guide to Physical and Chemical Deposition Methods

- Why is sputter coating used? Achieve Superior Film Quality and Uniformity

- On which factor properties of thin film varies? Master the Deposition Process for Optimal Performance

- What are the characteristics of a hot-wall CVD system? Key Benefits & Architectural Insights

- What is the CVD method of synthesis? A Guide to High-Purity Thin Film Deposition

- What is deposition on a substrate? The Ultimate Guide to Precision Thin-Film Coating

- What is the CVD method for lab grown diamonds? Growing a Gemstone from Gas

- What is the pressure in LPCVD? Master the Key to Superior Film Uniformity