In short, induction furnaces are used because they provide a clean, precise, and highly efficient method for melting metals. Unlike traditional furnaces that rely on burning fuel or electric arcs, an induction furnace heats the metal from within, preventing contamination from combustion byproducts and allowing for exceptionally tight temperature control. This makes it the superior choice for producing high-quality alloys and operating in modern, environmentally conscious foundries.

The decision to use an induction furnace is driven by the need for quality and control. Its core advantage lies in generating heat directly within the metal itself, which simultaneously prevents contamination, minimizes the loss of valuable elements, and increases energy efficiency.

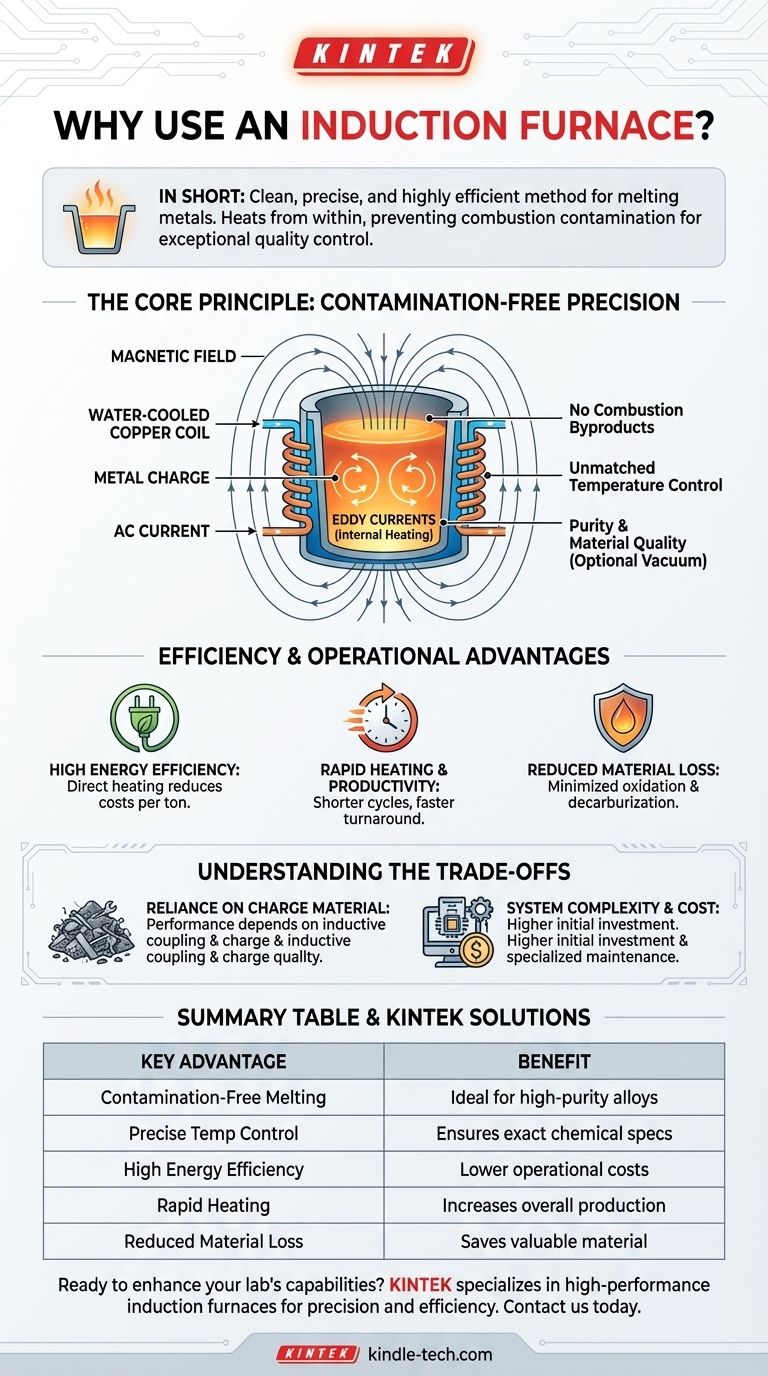

The Core Principle: Contamination-Free Precision

The primary technical advantage of an induction furnace stems directly from its method of heating. It does not burn fuel or create an electrical arc over the metal.

How Induction Heating Works

An induction furnace uses a water-cooled copper coil that surrounds a crucible containing the metal charge. When a powerful alternating current is passed through this coil, it creates a strong magnetic field.

This magnetic field induces powerful electrical currents (eddy currents) directly within the metal. The metal's natural electrical resistance causes it to heat up rapidly and melt, essentially turning the metal into its own heating element.

Unmatched Temperature Control

Because the heat is generated internally and is directly proportional to the power applied to the coil, the temperature can be regulated with extreme accuracy.

This precision is critical when melting complex alloys. It prevents overheating, which can burn off valuable and expensive alloying elements like chromium, nickel, or manganese, ensuring the final product meets exact chemical specifications.

Purity and Material Quality

Since there is no combustion, no byproducts like soot or sulfur are introduced into the melt. This complete separation from an external heat source results in exceptionally clean metal.

For the highest purity applications, this process can be performed inside a vacuum induction furnace, eliminating any chance of contamination from the air and producing alloys with superior performance characteristics.

Efficiency and Operational Advantages

Beyond quality, induction furnaces offer significant benefits in production speed and resource management, which are critical for any industrial operation.

High Energy Efficiency

Traditional furnaces waste enormous amounts of energy heating the furnace walls and the surrounding environment. In an induction furnace, nearly all the energy is directed into melting the metal charge.

This high level of efficiency translates directly into lower energy consumption and reduced operational costs per ton of metal produced.

Rapid Heating and Productivity

The direct heating method is incredibly fast, leading to much shorter melting cycles compared to fuel-fired furnaces.

This rapid turnaround increases production efficiency, allowing foundries to produce more material in less time and respond more quickly to demand.

Reduced Material Loss

Processes like oxidation (rusting) and decarburization (loss of carbon content) occur on the surface of hot metal. Because induction heating is so fast, the metal spends less time at high temperatures where these losses can occur.

This saves valuable material that would otherwise be lost as slag or scale, further improving the economic efficiency of the process.

Understanding the Trade-offs

While highly advantageous, induction furnaces are not the universal solution for all melting applications. Understanding their limitations is key to making an informed decision.

Reliance on Charge Material

The efficiency of an induction furnace depends on the "inductive coupling" between the coil and the metal charge. The size, shape, and type of scrap material can impact heating performance.

Poorly prepared or very loose charge material can lead to less efficient melting cycles compared to a dense, well-packed charge.

System Complexity and Cost

An induction furnace is a sophisticated system that includes a high-power electrical unit, a water-cooling system (chiller), and the furnace itself. This can represent a higher initial capital investment compared to simpler furnace types.

Maintenance also requires specialized knowledge of high-power electrical systems, which can be a consideration for some facilities.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your primary goals, balancing cost, quality, and operational needs.

- If your primary focus is high-value alloys and material purity: An induction furnace is the ideal choice due to its non-contaminating process and precise temperature control.

- If your primary focus is production efficiency and low energy costs: The rapid heating cycles and high energy efficiency of induction technology make it a powerful tool for productive foundries.

- If your primary focus is environmental compliance and worker safety: The clean, quiet, and emission-free operation of an induction furnace provides a clear advantage over combustion-based alternatives.

Ultimately, an induction furnace is the modern choice for melting processes where quality, control, and cleanliness are paramount.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Contamination-Free Melting | No combustion byproducts; ideal for high-purity alloys. |

| Precise Temperature Control | Prevents loss of valuable alloying elements; ensures exact chemical specs. |

| High Energy Efficiency | Direct internal heating reduces energy consumption and operational costs. |

| Rapid Heating | Shorter melting cycles increase overall production efficiency. |

| Reduced Material Loss | Faster process minimizes oxidation and decarburization. |

Ready to enhance your lab's metal melting capabilities?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precision and efficiency. Whether you are developing new alloys or require contamination-free melting for research, our solutions deliver the quality and control you need.

Contact us today via our [#ContactForm] to discuss how an induction furnace can benefit your specific application and explore our range of products tailored to laboratory needs.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How is temperature controlled in a furnace? Mastering Precise Thermal Management

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis