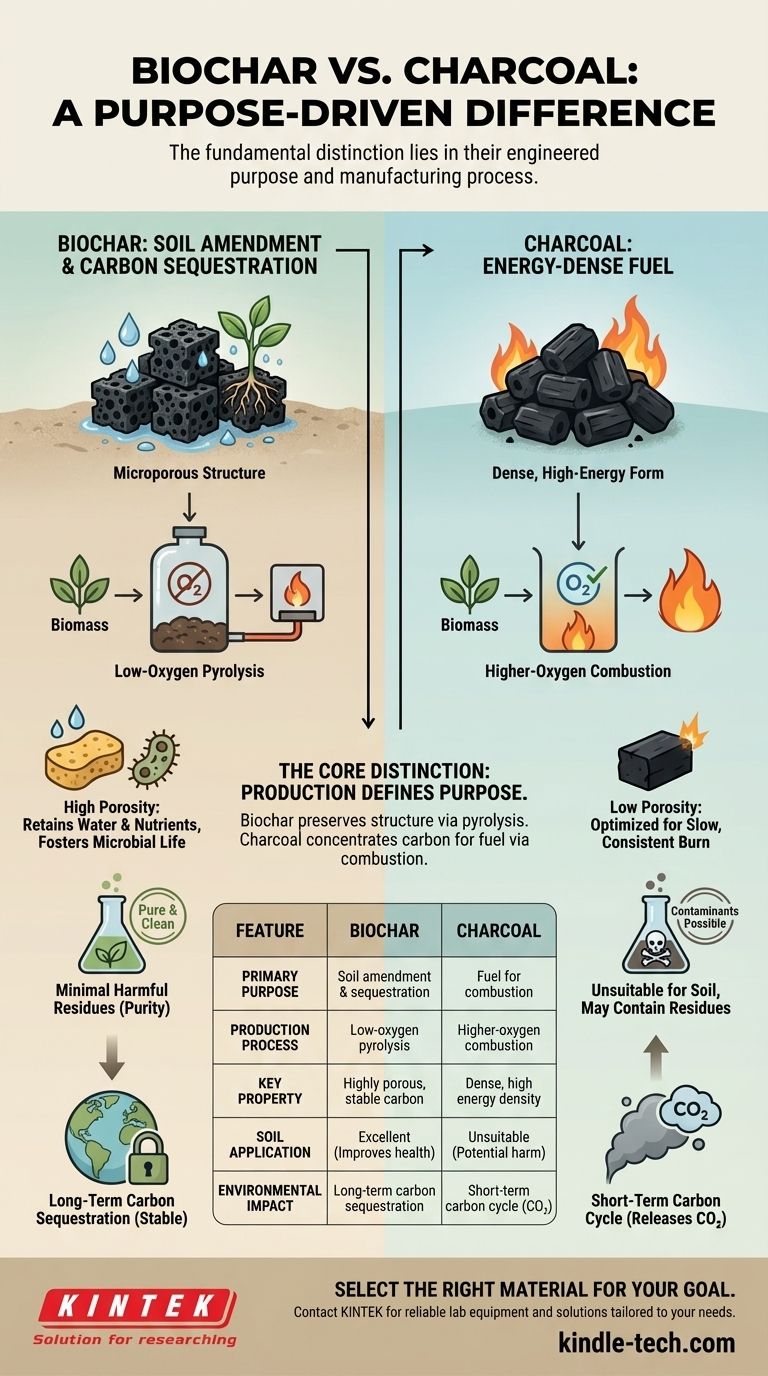

The fundamental difference is that biochar is not merely a type of charcoal; it is engineered for a completely different purpose. While both are made from biomass, biochar is produced specifically to be a stable, porous soil amendment, whereas charcoal is produced to be an energy-dense fuel. The term "better" depends entirely on your goal.

The core distinction lies in the manufacturing process. Biochar is created using low-oxygen pyrolysis to preserve a porous carbon structure for soil, while charcoal is made via combustion with more oxygen to create a product designed to be burned for energy.

Production Defines Purpose: Oxygen is the Key

The method used to heat the biomass determines the final product's properties and its ultimate use. The critical variable is the amount of oxygen present during heating.

Biochar: Low-Oxygen Pyrolysis

Biochar is created through a process called pyrolysis. This involves heating biomass (like wood or agricultural waste) to high temperatures in a container with very little or no oxygen.

This oxygen-starved environment prevents the material from fully combusting. Instead, it bakes off volatile compounds and leaves behind a stable, carbon-rich structure that is incredibly porous.

Charcoal: Higher-Oxygen Combustion

Traditional charcoal is also made by heating biomass, but with more oxygen present than in pyrolysis. The goal is not to preserve structure but to create a fuel.

This process burns off more of the original material, concentrating the carbon into a denser form that has high energy value when ignited.

The Resulting Properties: A Tale of Two Carbons

The difference in production leads to vastly different physical and chemical properties, making each material uniquely suited for its specific application.

Structure and Porosity

Biochar’s primary value comes from its microporous structure, which acts like a sponge. This high surface area allows it to absorb and retain water and nutrients, providing a stable habitat for beneficial soil microbes.

Charcoal is typically much denser and less porous. Its structure is optimized for a consistent, slow burn, not for holding water or housing microorganisms.

Purity and Contaminants

The controlled pyrolysis process for creating biochar is designed to minimize the formation of potentially harmful compounds like tars and polycyclic aromatic hydrocarbons (PAHs). Quality biochar is "clean" for agricultural use.

Charcoal production is often less controlled, and the resulting product can contain residues that are not suitable for adding to soil and could harm plant life.

Carbon Stability and Sequestration

Biochar is a form of long-term carbon sequestration. Its stable chemical structure resists decomposition for hundreds or even thousands of years, effectively locking carbon in the ground.

Charcoal is designed to be burned. It is a short-term carbon product, as all its stored carbon is released back into the atmosphere as CO2 upon combustion.

Understanding the Trade-offs: Not Better, Just Different

Choosing one over the other is a matter of function, not inherent superiority. Each has a role where it dramatically outperforms the other.

As a Soil Amendment

Biochar is the vastly superior choice for agricultural and horticultural use. Its ability to improve water retention, reduce nutrient leaching, and foster microbial life is its entire reason for being. Adding fuel-grade charcoal to soil would be ineffective at best.

As a Fuel Source

Charcoal is an excellent fuel, which is why it has been used for millennia for cooking and metallurgy. It has a higher energy density and is designed for combustion. Biochar, by contrast, is a very poor fuel source.

As an Environmental Tool

From a climate perspective, biochar is the "better" product. By locking carbon in the soil for centuries, it acts as a net negative emission technology. Charcoal, being a fuel, is part of the active carbon cycle.

How to Choose the Right Material for Your Goal

Your intended application is the only factor that matters when deciding between these two materials.

- If your primary focus is improving soil health and sequestering carbon: Biochar is the only correct choice, engineered specifically for its porosity, purity, and stability in soil.

- If your primary focus is creating an effective fuel for cooking or heating: Traditional charcoal is the superior option, designed specifically for high-energy combustion.

Understanding that their production methods create fundamentally different materials empowers you to select the right carbon for the right job.

Summary Table:

| Feature | Biochar | Charcoal |

|---|---|---|

| Primary Purpose | Soil amendment & carbon sequestration | Fuel for combustion |

| Production Process | Low-oxygen pyrolysis | Higher-oxygen combustion |

| Key Property | Highly porous, stable carbon | Dense, high energy density |

| Soil Application | Excellent: improves water retention & microbial life | Unsuitable: can contain harmful residues |

| Environmental Impact | Long-term carbon sequestration | Short-term carbon cycle (releases CO2) |

Ready to select the right material for your application?

Whether your project requires precise pyrolysis equipment for producing high-quality biochar or robust systems for other laboratory processes, KINTEK is your trusted partner. We specialize in providing reliable lab equipment and consumables tailored to your research and production needs.

Contact our experts today to discuss how we can support your goals with the right solutions!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Continuous Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis