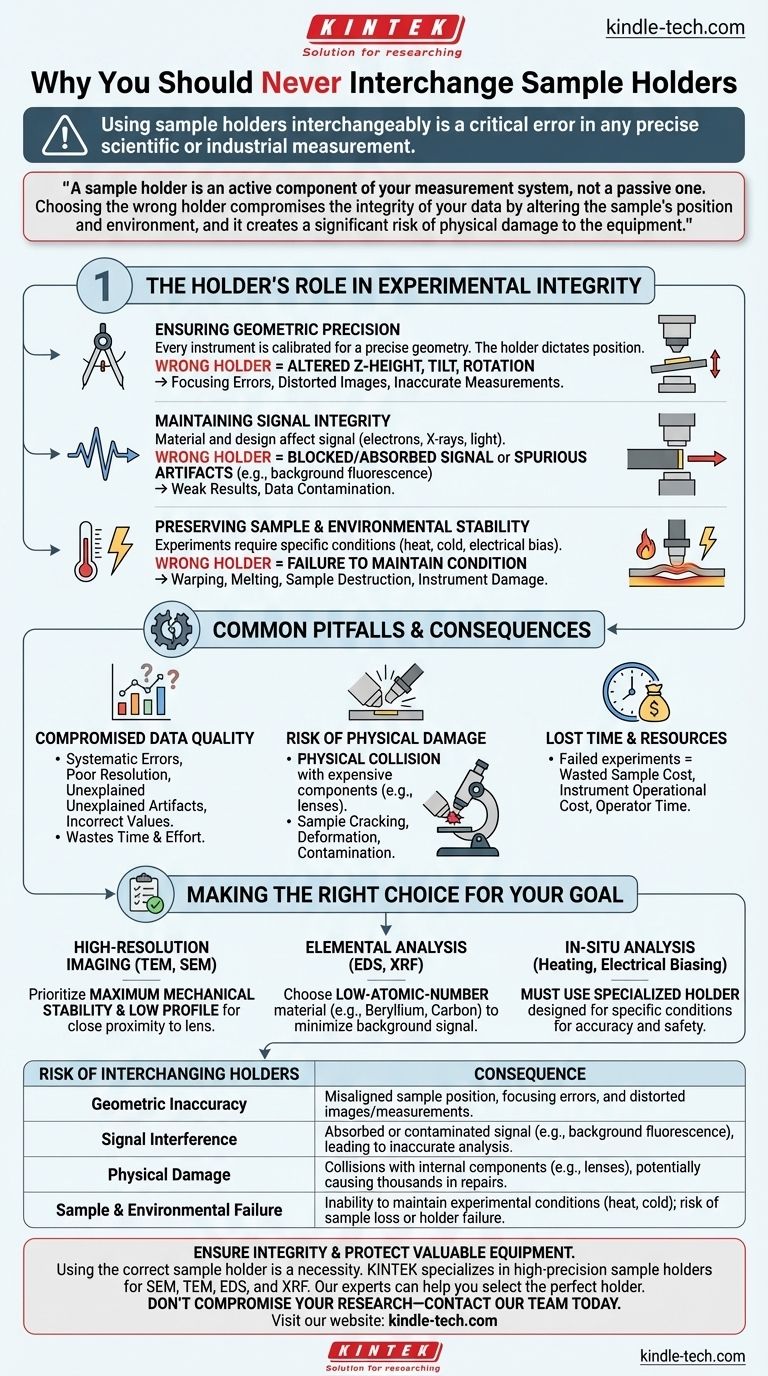

Using sample holders interchangeably is a critical error in any precise scientific or industrial measurement. These devices are not generic containers but highly specialized components engineered for a specific purpose. Interchanging them introduces uncontrolled variables that can invalidate your results, damage the sample, and in the worst cases, cause catastrophic failure of the instrument itself.

A sample holder is an active component of your measurement system, not a passive one. Choosing the wrong holder compromises the integrity of your data by altering the sample's position and environment, and it creates a significant risk of physical damage to the equipment.

The Holder's Role in Experimental Integrity

The fundamental mistake is viewing the holder as a simple platform. In reality, it is an integral part of the instrument's operational path, influencing everything from the signal source to the detector.

Ensuring Geometric Precision

Every advanced analytical instrument, from an electron microscope to a spectrometer, is calibrated for a precise geometry. The holder dictates the sample's position within this system.

Using the wrong holder can alter the Z-height (the distance from the sample to a lens or detector), the tilt, and the rotation capabilities. This deviation directly leads to focusing errors, distorted images, and inaccurate measurements because the sample is not where the instrument expects it to be.

Maintaining Signal Integrity

The material and design of the holder directly affect the signal you are trying to measure, whether it's electrons, X-rays, or light.

A holder that is too thick or made of a dense material can block or absorb the signal, leading to weak or non-existent results. Conversely, a holder made of the wrong material can generate its own spurious signals or artifacts—for example, producing background X-ray fluorescence that contaminates an elemental analysis.

Preserving Sample and Environmental Stability

Many experiments require the sample to be held under specific conditions, such as extreme heat, cold, or electrical bias.

Specialized in-situ holders are designed to provide these conditions reliably and safely. Using a standard holder in such an environment will fail to maintain the desired condition, and it may warp, melt, or break, destroying the sample and potentially damaging internal instrument components.

Common Pitfalls and Consequences

The consequences of using an incorrect holder range from subtle data corruption to immediate and expensive hardware failure. Understanding these risks is essential for any operator.

Compromised Data Quality

This is the most common and insidious outcome. Using the wrong holder can introduce systematic errors that make your results unreliable and non-repeatable. This includes poor resolution, unexplained artifacts, and incorrect quantitative values, wasting valuable instrument time and research effort.

Risk of Physical Damage

A holder that is not designed for a specific instrument may have incorrect dimensions. Inserting it can cause a physical collision with a microscope's objective lens or a detector, components that can cost tens of thousands of dollars to replace.

Furthermore, improper clamping mechanisms on the wrong holder can easily crack, deform, or contaminate a delicate sample, rendering it useless for further analysis.

Lost Time and Resources

Every failed experiment due to an avoidable error like holder mismatch represents a significant loss. This includes the cost of the sample, the operational cost of the instrument (which can be hundreds of dollars per hour), and the operator's time.

Making the Right Choice for Your Goal

Always verify that your holder is correct for both the instrument and the specific experiment you are conducting. When in doubt, consult the instrument's manual or a senior lab member.

- If your primary focus is high-resolution imaging (e.g., TEM, SEM): Prioritize holders designed for maximum mechanical stability and a low profile to get as close as possible to the final lens.

- If your primary focus is elemental analysis (e.g., EDS, XRF): Choose a holder made from a low-atomic-number material, such as beryllium or carbon, to minimize background signal interference.

- If your primary focus is in-situ analysis (e.g., heating, electrical biasing): You must use the specialized holder explicitly designed for those conditions to ensure both accuracy and safety.

Ultimately, treating the sample holder with the same diligence as the instrument itself is fundamental to producing reliable and repeatable scientific data.

Summary Table:

| Risk of Interchanging Holders | Consequence |

|---|---|

| Geometric Inaccuracy | Misaligned sample position, focusing errors, and distorted images/measurements. |

| Signal Interference | Absorbed or contaminated signal (e.g., background fluorescence), leading to inaccurate analysis. |

| Physical Damage | Collisions with internal components (e.g., lenses), potentially causing thousands in repairs. |

| Sample & Environmental Failure | Inability to maintain experimental conditions (heat, cold); risk of sample loss or holder failure. |

Ensure the integrity of your laboratory work and protect your valuable equipment. Using the correct sample holder is not just a recommendation—it's a necessity for accurate, repeatable results. KINTEK specializes in providing high-precision lab equipment and consumables, including a wide range of application-specific sample holders for techniques like SEM, TEM, EDS, and XRF. Our experts can help you select the perfect holder for your specific instrument and experimental needs. Don't compromise your research—contact our team today for a consultation and ensure your lab is equipped for success.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity

- What are the factors that affect melting and boiling point? Unlock the Science of Phase Transitions

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy