From a technical standpoint, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is often considered superior to conventional Chemical Vapor Deposition (CVD) because it uses an energy-rich plasma, not just high heat, to drive the deposition process. This fundamental difference allows PECVD to operate at significantly lower temperatures, offering greater material compatibility, higher efficiency, and tighter control over the final film's properties.

The core distinction is not that one method is universally "better," but that PECVD's use of plasma instead of pure heat solves the primary limitation of traditional CVD: high-temperature requirements. This makes PECVD indispensable for modern applications involving heat-sensitive substrates and complex material engineering.

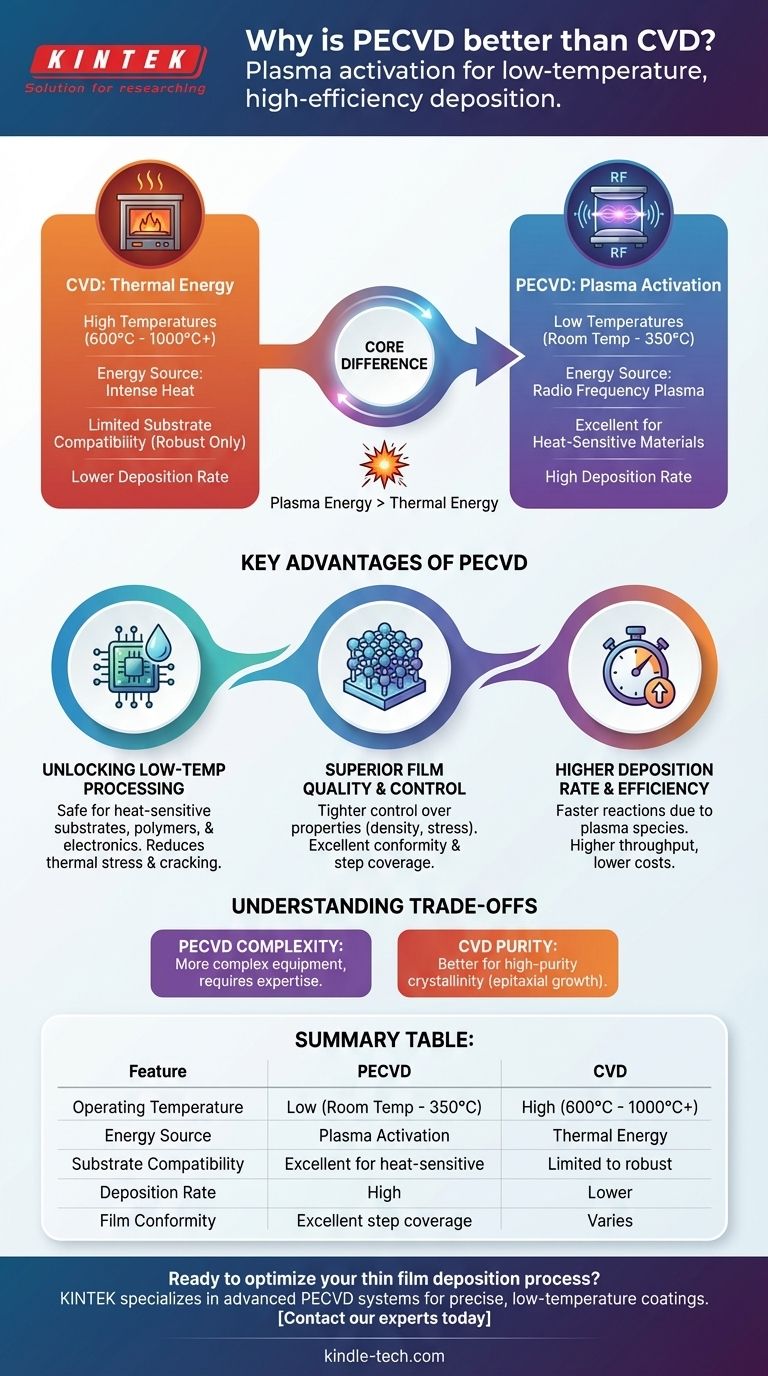

The Core Difference: Energy Source

To understand the advantages, you must first grasp the fundamental mechanism that separates these two processes. The choice between them comes down to how you supply the energy needed for the chemical reaction.

How Traditional CVD Works

Traditional thermal CVD relies exclusively on high temperatures, often ranging from 600°C to over 1000°C.

This intense heat provides the thermal energy required to break down precursor gases and allow them to react and deposit as a thin film on the substrate's surface.

The PECVD Advantage: Plasma Activation

PECVD accomplishes the same goal but at much lower temperatures (often room temperature to 350°C).

Instead of heat, it uses a radio frequency (RF) or microwave field to ignite the precursor gases into a plasma. This plasma is a highly energetic state of matter containing ions and free radicals that are extremely reactive, enabling deposition without the need for extreme thermal energy.

Key Advantages of PECVD in Practice

This shift from thermal energy to plasma activation creates several significant, practical benefits that drive its adoption in advanced manufacturing.

Unlocking Low-Temperature Processing

The most critical advantage is the ability to deposit films at low temperatures. This avoids damaging heat-sensitive substrates like plastics, organic materials, or fully fabricated electronic devices that already contain delicate circuitry.

It also reduces thermal stress between the substrate and the deposited film, especially when their thermal expansion coefficients differ. This dramatically reduces the risk of the film cracking or delaminating.

Superior Film Quality and Control

The plasma environment provides additional variables for process control, such as power, pressure, and gas flow, which are not available in thermal CVD.

This allows for tighter control over the film's properties. Engineers can precisely tune characteristics like density, stress, chemical resistance, and even optical or electrical properties by adjusting the plasma parameters.

Furthermore, PECVD is known for its excellent conformity and step coverage, meaning it can deposit a highly uniform film over complex, uneven, or three-dimensional surfaces.

Higher Deposition Rate and Efficiency

The highly reactive species in the plasma accelerate the chemical reactions. This results in significantly higher deposition rates compared to many thermal CVD processes.

Faster deposition times translate directly to higher throughput and lower operational costs in a manufacturing environment.

Understanding the Trade-offs

While powerful, PECVD is not a universal replacement for all CVD processes. An objective assessment requires acknowledging its complexities.

Equipment and Process Complexity

A PECVD system, with its RF power generators, matching networks, and advanced vacuum controls, is inherently more complex and often more expensive than a simple thermal CVD furnace.

Tuning the process also requires more expertise. Incorrect plasma parameters can lead to non-uniformity or even damage the substrate through ion bombardment, a risk not present in thermal CVD.

Film Purity and Crystallinity

For applications demanding the absolute highest film purity or a specific crystalline structure (like epitaxial growth), high-temperature thermal CVD can sometimes be superior. The high heat provides the energy for atoms to arrange themselves into a highly ordered, low-defect crystal lattice.

The lower temperatures and complex chemical environment of PECVD can sometimes result in films with higher hydrogen incorporation or an amorphous (non-crystalline) structure, which may be undesirable for certain electronic or optical applications.

Making the Right Choice for Your Application

Ultimately, the decision rests on the specific requirements of your substrate, your desired film properties, and your manufacturing goals.

- If your primary focus is depositing on heat-sensitive substrates (like polymers or pre-fabricated electronics): PECVD is the clear and often only viable choice due to its low-temperature processing.

- If your primary focus is achieving high deposition speed and throughput: PECVD often provides a significant advantage due to its plasma-accelerated reaction rates.

- If your primary focus is creating a highly uniform coating over complex, 3D topography: PECVD's excellent step coverage makes it the superior choice for ensuring complete and even coating.

- If your primary focus is growing a high-purity, single-crystal film on a robust substrate: Traditional thermal CVD may be a more reliable and straightforward method.

By understanding the core difference between thermal and plasma activation, you are empowered to select the precise deposition tool for your specific engineering goal.

Summary Table:

| Feature | PECVD | CVD |

|---|---|---|

| Operating Temperature | Low (Room Temp - 350°C) | High (600°C - 1000°C+) |

| Energy Source | Plasma Activation | Thermal Energy |

| Substrate Compatibility | Excellent for heat-sensitive materials | Limited to high-temperature substrates |

| Deposition Rate | High | Lower |

| Film Conformity | Excellent step coverage | Varies |

Ready to optimize your thin film deposition process? KINTEK specializes in advanced lab equipment, including PECVD systems, to help you achieve precise, low-temperature coatings for heat-sensitive substrates. Our expertise ensures you get the right solution for higher throughput and superior film quality. Contact our experts today to discuss how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods