In short, plasma is used in sputtering because it is the most effective medium for creating and accelerating ions. These high-energy ions act as microscopic projectiles, striking a target material with enough force to physically knock atoms loose. This process, known as sputtering, is the foundational mechanism for depositing high-quality thin films.

Sputtering is fundamentally a physical process of momentum transfer, not a chemical or thermal one. Plasma is simply the most practical and controllable way to generate the massive quantity of ion "bullets" needed to bombard a target and eject its atoms onto a substrate.

The Core Challenge: Liberating Target Atoms

To understand plasma's role, we must first understand the fundamental goal of sputtering: moving atoms from a solid source (the target) onto another surface (the substrate) in a highly controlled manner.

What is Sputtering?

Sputtering is a Physical Vapor Deposition (PVD) technique. Unlike thermal evaporation, which boils a material, sputtering uses pure kinetic energy to eject atoms.

This method allows for the deposition of a vast range of materials, including metals and ceramics with extremely high melting points, which would be impractical to evaporate.

The Need for a Projectile

To physically knock an atom out of a solid target, you must hit it with something that has sufficient momentum.

The solution is to use a heavy, energetic particle as a projectile. In a vacuum chamber, the ideal projectile is an ion—an atom that has been electrically charged.

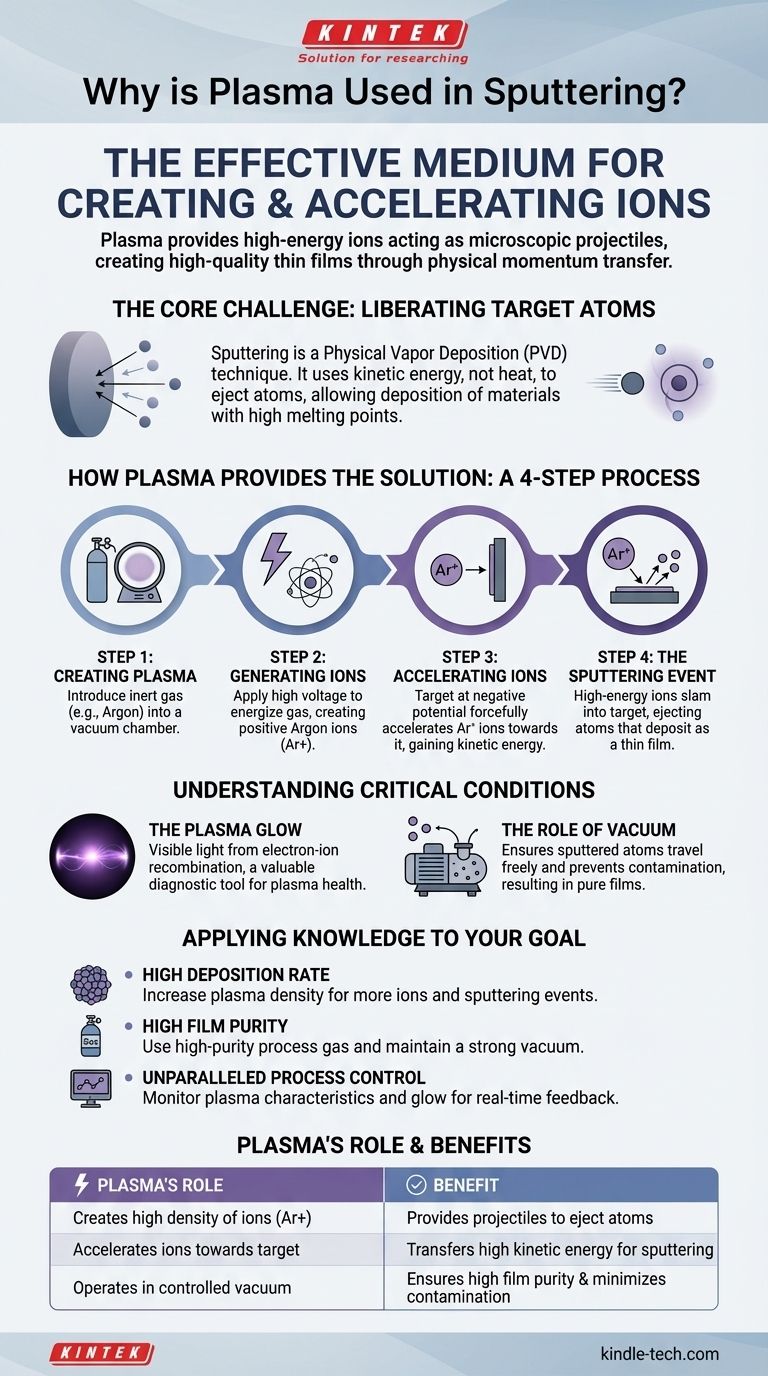

How Plasma Provides the Solution

Plasma is often called the fourth state of matter. It is a gas that has been energized to the point where electrons are stripped from their atoms, creating a mixture of positively charged ions and free electrons.

Step 1: Creating the Plasma

The process begins by introducing a small amount of an inert gas, typically Argon, into a vacuum chamber. Argon is chosen because it is heavy enough to cause effective sputtering and chemically inert, meaning it won't react with the target material.

Step 2: Generating the Ions

A high voltage is then applied between the target (which acts as the cathode, or negative electrode) and the chamber walls. This strong electric field energizes the Argon gas, stripping electrons from the Argon atoms and creating a self-sustaining plasma filled with positive Argon ions (Ar+).

Step 3: Accelerating the Ions

Because the target is held at a strong negative potential, the positively charged Argon ions are forcefully accelerated directly toward it. They gain significant kinetic energy during this journey.

Step 4: The Sputtering Event

These high-energy Argon ions slam into the surface of the target material. The impact transfers momentum from the ion to the target atoms, causing them to be ejected, or "sputtered," from the surface. These ejected atoms then travel through the vacuum and deposit as a thin film onto the substrate.

Understanding the Byproducts and Conditions

While the ions are the primary actors, other elements of the process are critical for control and observation.

What the Plasma Glow Indicates

The characteristic glow seen during sputtering is a useful byproduct, but it is not the cause of the sputtering itself. This glow occurs when free electrons in the plasma lose energy and recombine with the positive ions.

The excess energy from this recombination is released as light. The color and intensity of this glow can serve as a valuable diagnostic tool, indicating the health and stability of the plasma.

The Critical Role of a Vacuum

The entire process must occur in a high vacuum. This ensures two things: first, that the sputtered atoms can travel from the target to the substrate without colliding with other gas molecules, and second, that the resulting film is pure and not contaminated by reactive gases like oxygen.

Applying this Knowledge to Your Goal

Understanding the role of plasma allows you to control the outcome of the deposition process.

- If your primary focus is a high deposition rate: Your goal is to create a denser plasma, which generates more ions and thus increases the number of sputtering events per second.

- If your primary focus is film purity: You must use a high-purity process gas (like Argon) and maintain a strong vacuum to prevent unwanted atoms from being incorporated into your film.

- If your primary focus is process control: Monitoring the plasma's electrical characteristics and its visible glow provides real-time feedback on the stability and efficiency of your sputtering run.

By mastering the creation and manipulation of plasma, you transform sputtering from a complex phenomenon into a precise engineering tool.

Summary Table:

| Plasma's Role in Sputtering | Benefit |

|---|---|

| Creates a high density of ions (Ar+) | Provides the projectiles needed to eject target atoms |

| Accelerates ions toward the target | Transfers high kinetic energy for effective sputtering |

| Enables deposition of high-melting-point materials | A versatile Physical Vapor Deposition (PVD) technique |

| Operates in a controlled vacuum environment | Ensures high film purity and minimizes contamination |

Ready to achieve precise, high-quality thin films with your sputtering process?

KINTEK specializes in advanced lab equipment and consumables for all your deposition needs. Our expertise in plasma-based systems can help you optimize for high deposition rates, superior film purity, and unparalleled process control.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

People Also Ask

- What are the stages of an electric arc furnace? The Complete Tap-to-Tap Cycle Explained

- What is the difference between short path and thin film? Choosing the Right Distillation Method for Your Lab

- What are the factors that affect sample size? Optimize Your Study's Power and Precision

- What are the limitations of this FTIR technique? Overcome Molecular Analysis Challenges

- What is titanium used for in manufacturing? Leveraging High-Performance Properties for Critical Applications

- How many types of hardening techniques are there? A Multi-Layered Security Strategy Explained

- How does sintering work in metals? A Guide to Solid-State Diffusion for Strong Parts

- What is the characterization of bio-oil? A Deep Dive into Its Properties and Potential