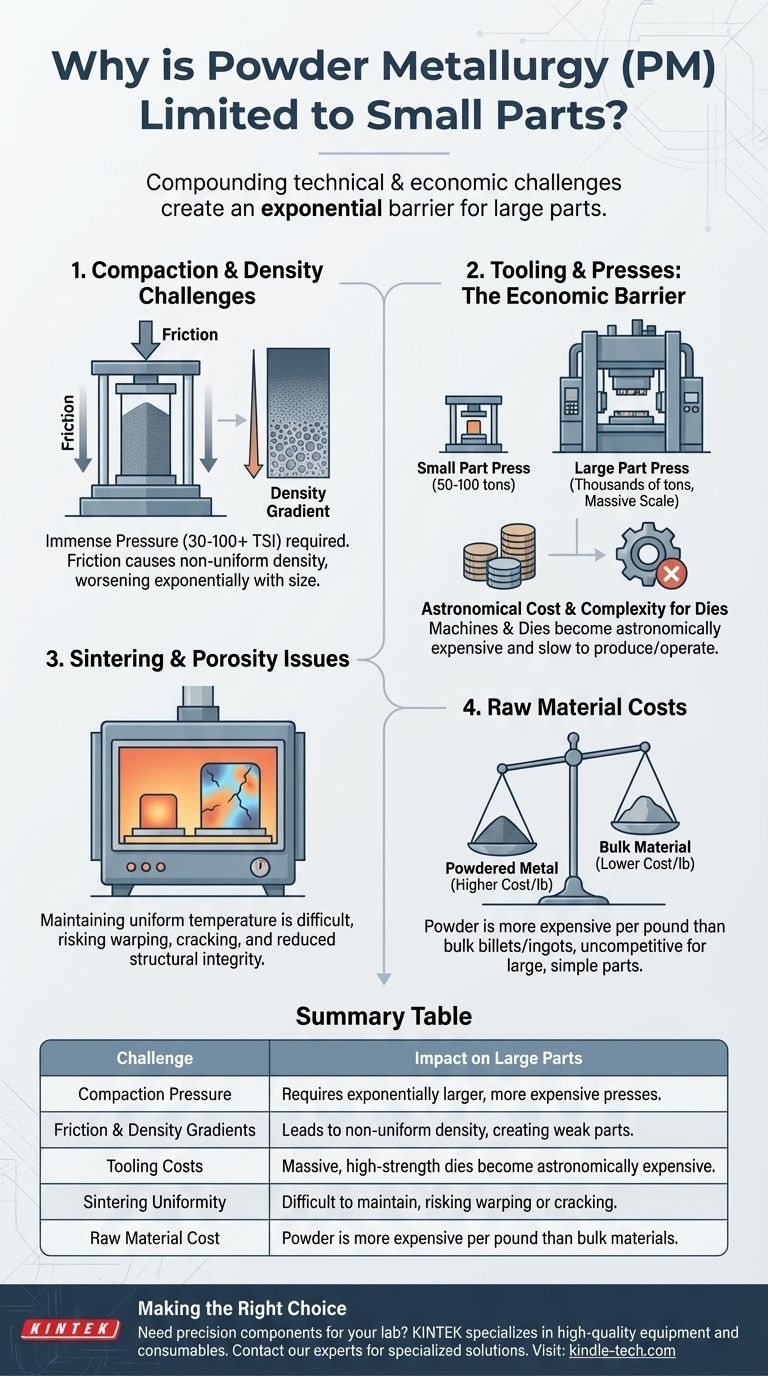

In practice, powder metallurgy (PM) is not strictly limited to small parts, but it is overwhelmingly chosen for them due to a series of compounding technical and economic challenges. The core issues are the immense pressures required for compaction, the prohibitive cost of large-scale tooling, and the difficulty of achieving uniform density as part volume increases.

The fundamental reason powder metallurgy is not used for large parts is that the force needed to overcome internal friction and uniformly compact the powder increases exponentially with the part's size. This makes the required presses and tooling astronomically expensive and technically impractical.

The Core Challenge: Compaction and Density

At the heart of the PM process is the need to press loose metal powder into a solid, uniform shape. This is where the size limitations begin.

The Role of Compaction Pressure

Compaction is not simply about squeezing powder. The goal is to apply enough pressure to force the individual powder particles into intimate contact, deforming them and mechanically interlocking them to create a "green" compact with enough strength to be handled.

This process requires extremely high pressures, often ranging from 30 to 100+ tons per square inch (TSI), to achieve the target density.

The Problem of Friction

As the compaction punch presses down on the powder, friction acts as a powerful opposing force. Friction occurs between the powder particles themselves and, crucially, between the powder and the walls of the die.

This friction causes the pressure to diminish as it travels down through the powder column. The top of the part experiences the full applied pressure, but the bottom receives significantly less. This creates a density gradient, where the part is denser at the top than at the bottom.

The Exponential Force Requirement

For a small, thin part, this density variation is manageable. But as the part gets larger—either in its cross-sectional area or its height—the problem escalates dramatically.

A larger cross-section requires a proportionally larger total force to achieve the same pressure (Force = Pressure × Area). A taller part suffers from much greater pressure loss due to friction, resulting in unacceptable density variations and a structurally unsound final component.

The Practical Limits of Tooling and Presses

The physical reality of building machines to overcome these forces creates a hard economic barrier.

The Scale of Compaction Presses

The presses used in PM are rated in tonnage. A press for a small component might be rated for 50 or 100 tons.

To make a part just a few times larger, you would need a press capable of delivering thousands of tons of force. These machines are massive, slow, and extraordinarily expensive to build, operate, and maintain.

The Cost and Complexity of Tooling

The die set—the cavity and punches that define the part's shape—must withstand these immense, repeated compaction forces. For a large component, the tooling would need to be a massive, precisely machined block of high-strength tool steel.

The cost to design, manufacture, and heat-treat such a large tool can easily run into the hundreds of thousands or even millions of dollars, making it unjustifiable for all but the most extreme use cases.

Understanding the Trade-offs

Beyond compaction, other factors make PM less suitable for large parts compared to methods like casting or forging.

The Sintering Hurdle

After compaction, the green part is heated in a process called sintering, where the particles bond metallurgically. Sintering a very large part uniformly is a major challenge.

Maintaining a precise, consistent temperature across a large volume is difficult. Any temperature gradients can lead to warping, cracking, or inconsistent material properties throughout the part. The energy costs to heat such a large mass are also substantial.

The Porosity Problem

A key characteristic of PM parts is their inherent porosity. While high pressure reduces it, some level of porosity almost always remains. This makes PM parts inherently less strong than a fully dense part made from wrought metal.

In a large part, where achieving uniform high density is already a problem, the resulting porosity can significantly compromise its structural integrity, making it unsuitable for high-stress applications.

Raw Material Costs

Powdered metals are more expensive per pound than the bulk billets, ingots, or bars used in forging and machining. For small, complex parts, this is offset by the minimal material waste. For a large, simple part, the high raw material cost of the powder makes PM economically uncompetitive.

Making the Right Choice for Your Goal

Ultimately, every manufacturing process has an ideal application window. Understanding PM's strengths helps clarify why it thrives in the small-part domain.

- If your primary focus is mass production of small, geometrically complex parts: PM is an exceptional choice due to its high precision, excellent repeatability, and minimal material waste.

- If your primary focus is creating unique material alloys or composites: PM is uniquely capable of blending materials that cannot be mixed by melting, regardless of size.

- If your primary focus is producing a large, structurally robust component: You should strongly consider alternative methods like casting, forging, or machining from bulk material.

Choosing the right manufacturing process requires understanding these fundamental trade-offs.

Summary Table:

| Challenge | Impact on Large Parts |

|---|---|

| Compaction Pressure | Requires exponentially larger, more expensive presses (thousands of tons). |

| Friction & Density Gradients | Leads to non-uniform density, creating weak, structurally unsound parts. |

| Tooling Costs | Massive, high-strength dies become astronomically expensive to produce. |

| Sintering Uniformity | Difficult to maintain consistent temperature, risking warping or cracking. |

| Raw Material Cost | Metal powder is more expensive per pound than bulk materials for large parts. |

Need precision components for your lab? KINTEK specializes in high-quality lab equipment and consumables, perfect for applications where precision and material integrity are paramount. Whether your project requires advanced materials or specialized manufacturing insights, our expertise can help you achieve superior results. Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the temperature of a hydraulic system? Maintain Optimal Performance & Prevent Damage

- What are hydraulic presses used for? Powering Industries with Immense, Controlled Force

- Which is the most common type of press used in industry? Hydraulic vs. Mechanical

- What role does a Benchtop Hydraulic Press play in sample preparation for solubility tests? Optimize Sample Uniformity.

- What role do laboratory hydraulic presses and stainless steel molds play in the pre-treatment of LLZO powders? | KINTEK

- What can destroy a hydraulic press? Avoid These Common & Costly Mistakes

- How does high pressure from a hydraulic press affect LLZO ceramic pellets? Optimizing Density for Peak Performance

- What is the difference between mechanical press and hydraulic press? Speed vs. Control for Your Production