In thin film deposition, the vacuum is not just a condition; it is a critical enabler. A vacuum environment is essential for two fundamental reasons: it removes atmospheric gases that would contaminate the film, and it allows the coating material to travel unimpeded from its source to the substrate. This control over purity and particle transport is what ensures the structural integrity and desired performance of the final coating.

The quality of a thin film is ultimately defined by what isn't present. A vacuum is crucial for eliminating unwanted atmospheric molecules that would otherwise interfere with the process, allowing for the controlled, straight-line travel of coating particles necessary to build a pure and dense film.

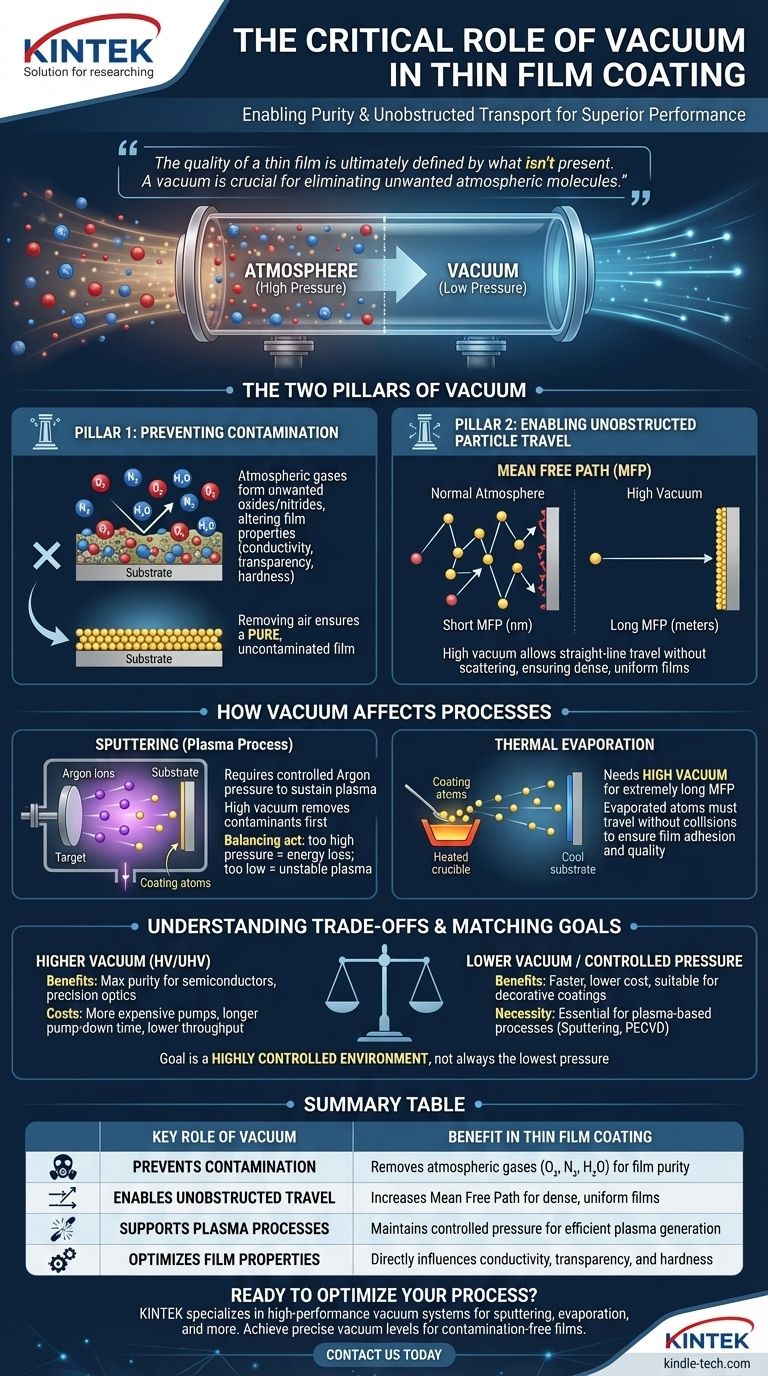

The Two Pillars of Vacuum in Thin Film Deposition

The necessity of a vacuum can be understood by focusing on two primary objectives: achieving purity and enabling efficient particle travel.

Pillar 1: Preventing Contamination

The air around us is a dense mixture of gases, primarily nitrogen and oxygen, along with water vapor and other trace elements.

When left in the deposition chamber, these atmospheric molecules will inevitably be incorporated into the growing film. This leads to the formation of unwanted compounds, such as oxides and nitrides.

This contamination drastically alters the film's desired properties, negatively impacting its electrical conductivity, optical transparency, or mechanical hardness. Removing the air is the first step to creating a pure, uncontaminated film.

Pillar 2: Enabling Unobstructed Particle Travel

For a coating to form, individual atoms or molecules of the source material must travel through the chamber and land on the substrate.

This journey needs to be a straight line. The concept that governs this is the Mean Free Path (MFP)—the average distance a particle can travel before colliding with another gas particle.

In normal atmosphere, the MFP is incredibly short, measured in nanometers. In a high vacuum, the MFP can extend to meters, longer than the chamber itself. This ensures coating particles travel directly to the substrate without being scattered or losing energy.

How Vacuum Affects Specific Deposition Processes

While the core principles are the same, the ideal vacuum level and its role can vary depending on the deposition technique.

For Sputtering and Plasma Processes

Sputtering does not occur in a perfect vacuum. First, a high vacuum is created to remove atmospheric contaminants. Then, a small, controlled amount of an inert process gas, typically Argon, is introduced.

This controlled, low-pressure environment is necessary to strike and sustain a plasma. The plasma's ionized Argon atoms are what bombard the source material, "sputtering" atoms off toward the substrate.

The vacuum level here is a balancing act. If the pressure is too high, the sputtered atoms will collide too often with Argon atoms, losing energy and failing to create a dense film. If the pressure is too low, there won't be enough Argon atoms to sustain the plasma efficiently.

For Thermal Evaporation

In thermal evaporation, a material is heated in a crucible until it evaporates, traveling to and condensing on the cooler substrate.

This process is highly dependent on an extremely long Mean Free Path. It requires a high vacuum to ensure the evaporated atoms do not collide with any residual air molecules.

Such collisions would cool the evaporated atoms or scatter them, preventing them from reaching the substrate with enough energy to form a high-quality, adherent film.

Understanding the Trade-offs

Choosing the right vacuum level is a technical and economic decision, not simply a race for the lowest possible pressure.

The Cost of Higher Vacuum

Achieving higher levels of vacuum (High Vacuum or Ultra-High Vacuum) requires more sophisticated and expensive equipment, such as turbo or cryogenic pumps.

Furthermore, reaching these lower pressures takes significantly more time, known as "pump-down time." This directly reduces throughput and increases the operational cost per cycle.

The Problem of "Too Much" Vacuum

As noted with sputtering, some critical processes require a specific gas pressure to function. For any plasma-enhanced technique, a perfect vacuum is unusable.

The goal is not always the highest possible vacuum, but rather the creation of a highly controlled environment, free of contaminants, with the precise pressure needed for the specific process.

Matching the Vacuum Level to Your Goal

The required vacuum level is dictated entirely by the desired properties of the final film and the deposition method used.

- If your primary focus is high-purity films (e.g., for semiconductors or precision optics): A higher vacuum level (HV or UHV) is non-negotiable to minimize contamination from reactive gases.

- If your primary focus is a standard metallic coating (e.g., for decorative purposes): A moderate vacuum level is often sufficient, providing a good balance between film quality, process speed, and cost.

- If you are running a plasma-based process (e.g., sputtering or PECVD): Your goal is to achieve the optimal process pressure for your specific gas, which is necessary to sustain the plasma efficiently after the initial pump-down.

Ultimately, controlling the vacuum is controlling the fundamental environment where your thin film is born, directly defining its final quality and performance.

Summary Table:

| Key Role of Vacuum | Benefit in Thin Film Coating |

|---|---|

| Prevents Contamination | Removes atmospheric gases (O₂, N₂, H₂O) to avoid oxide/nitride formation, ensuring film purity. |

| Enables Unobstructed Travel | Increases Mean Free Path, allowing coating particles to travel directly to the substrate for dense, uniform films. |

| Supports Plasma Processes | Maintains controlled pressure for sputtering and PECVD by enabling efficient plasma generation with inert gases like Argon. |

| Optimizes Film Properties | Directly influences electrical conductivity, optical transparency, and mechanical hardness of the final coating. |

Ready to optimize your thin film deposition process?

At KINTEK, we specialize in high-performance lab equipment, including vacuum systems tailored for sputtering, thermal evaporation, and other coating techniques. Our solutions help you achieve the precise vacuum levels needed for contamination-free, high-quality films—whether you're working on semiconductors, optics, or decorative coatings.

Contact us today to discuss your specific requirements and discover how our expertise can enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing