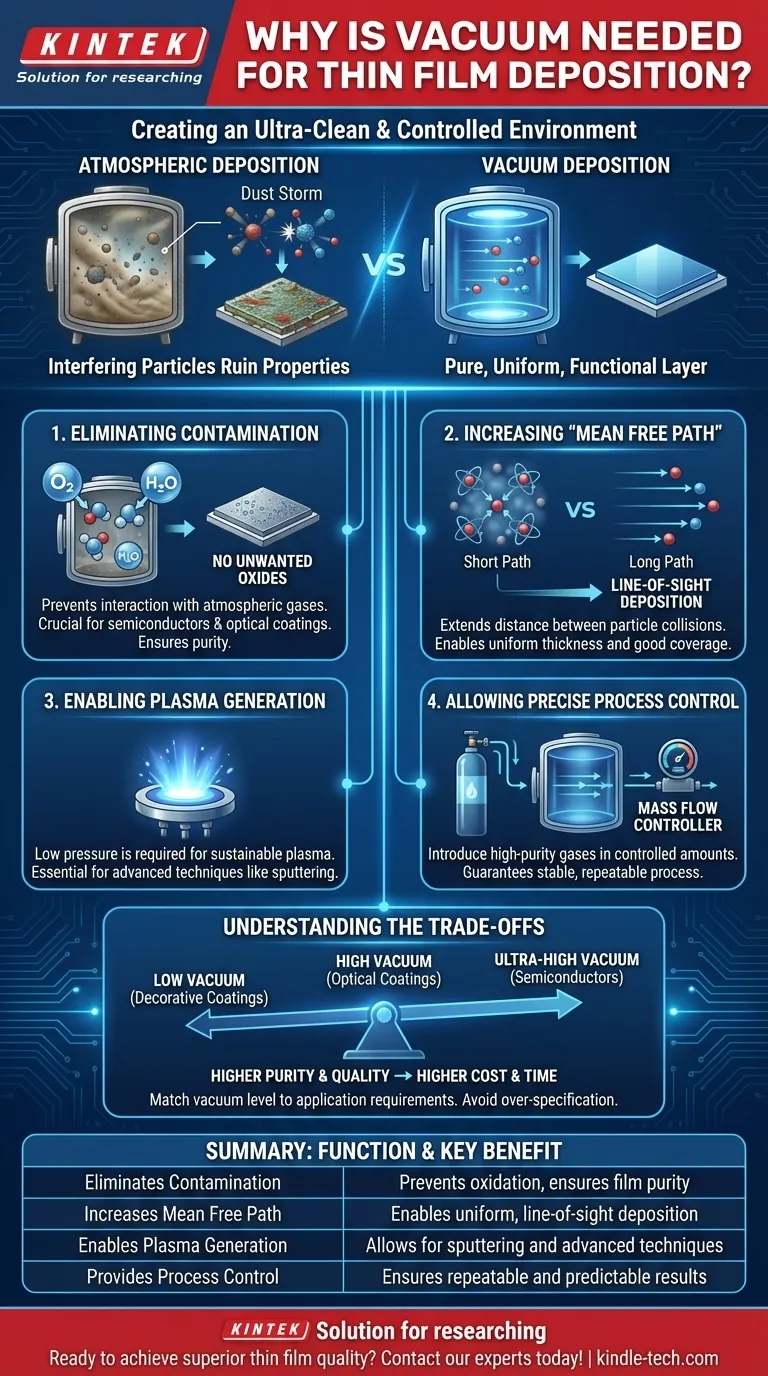

At its core, vacuum is required for thin film deposition to create an ultra-clean and controlled environment. This ensures that only the desired material is deposited onto the target surface (the substrate), preventing contamination from atmospheric gases like oxygen, nitrogen, and water vapor that would otherwise ruin the film's properties.

Creating a thin film without a vacuum is like trying to paint a microscopic circuit during a dust storm. The vacuum removes all the interfering "dust"—the atmospheric particles—so that the deposited material can form a pure, uniform, and functional layer.

The Core Functions of Vacuum in Deposition

The vacuum environment is not merely empty space; it is an active and essential component of the deposition process. It serves four primary functions that directly impact the quality, purity, and structure of the final film.

Function 1: Eliminating Contamination

Atmospheric air is dense with particles that are highly reactive. Gases like oxygen and water vapor will immediately interact with both the deposition material and the substrate surface.

This leads to the formation of unwanted oxides and other compounds within the film. For applications like semiconductors or optical coatings, even minuscule levels of contamination can completely alter the film's electrical or optical properties, rendering it useless.

Function 2: Increasing the "Mean Free Path"

Mean free path is the average distance a particle can travel before colliding with another particle. In the atmosphere, this distance is incredibly short—nanometers.

By creating a vacuum, we dramatically reduce the density of gas molecules, extending the mean free path to meters. This ensures that atoms from the deposition source travel in a straight, uninterrupted line to the substrate, a condition known as line-of-sight deposition. This is critical for achieving uniform film thickness and good coverage over complex surface topographies.

Function 3: Enabling Plasma Generation

Many advanced deposition techniques, particularly sputtering, rely on the creation of plasma. Plasma is a state of matter where gas atoms are ionized, and it can only be sustained at very low pressures.

Attempting to generate a stable plasma at atmospheric pressure is impossible for these processes. The vacuum chamber provides the low-pressure environment necessary to initiate and control the plasma that is used to eject material from a source target.

Function 4: Allowing Precise Process Control

Once unwanted atmospheric gases are removed, the vacuum chamber becomes a blank canvas. This allows engineers to introduce specific, high-purity process gases (like argon for sputtering) in precisely controlled amounts.

Using mass flow controllers, the composition and pressure of the chamber's environment can be managed with extreme accuracy. This guarantees that the deposition process is stable, predictable, and, most importantly, repeatable from one run to the next.

Understanding the Trade-offs

While vacuum is essential, the level of vacuum required presents a trade-off between cost, time, and the desired film quality. Achieving higher purity requires more significant investment.

Vacuum Levels Matter

Not all processes require the same vacuum level. A "low vacuum" might be sufficient for a simple decorative coating, while a semiconductor device requires an ultra-high vacuum (UHV) to achieve the necessary electronic purity.

The Cost of Purity

Reaching higher vacuum levels (High Vacuum and Ultra-High Vacuum) requires more sophisticated and expensive pumping systems and instrumentation. It also increases the "pump-down" time needed to evacuate the chamber before deposition can begin, which impacts manufacturing throughput and cost.

The key is to match the vacuum level to the specific requirements of the film's application, avoiding the unnecessary cost and time of over-specification.

How to Choose the Right Approach

Your choice of vacuum level is dictated entirely by the end-use of the thin film. There is no one-size-fits-all answer.

- If your primary focus is semiconductor fabrication or quantum devices: Ultra-high vacuum (UHV) is non-negotiable to achieve extreme purity and perfect material composition.

- If your primary focus is high-performance optical coatings: High vacuum (HV) is critical to minimize contamination that would otherwise absorb or scatter light.

- If your primary focus is general protective or decorative coatings: A lower-grade industrial vacuum is often sufficient to prevent major oxidation and ensure basic adhesion, balancing performance with cost.

Ultimately, the vacuum is the invisible foundation upon which modern thin film technology is built, enabling the creation of materials that define our technological world.

Summary Table:

| Function of Vacuum | Key Benefit |

|---|---|

| Eliminates Contamination | Prevents oxidation and ensures film purity |

| Increases Mean Free Path | Enables uniform, line-of-sight deposition |

| Enables Plasma Generation | Allows for sputtering and other advanced techniques |

| Provides Process Control | Ensures repeatable and predictable results |

Ready to achieve superior thin film quality in your lab? The right vacuum environment is the foundation of success. KINTEK specializes in lab equipment and consumables, providing the reliable vacuum solutions and expert support you need for semiconductor, optical, or protective coating applications. Contact our experts today to discuss how we can help you optimize your deposition process for purity and performance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What does flexibility mean in the context of a deposition system? Optimize Your R&D Adaptability

- Can monocrystalline graphene be grown on polycrystalline metal substrates? Unlock High-Quality CVD Graphene Synthesis

- What explains why carbon nanotubes make good catalysts? Unlock Their Unique Catalytic Power

- What are the benefits of CVD coating? Achieve Superior Hardness and Uniform Coverage

- What are the techniques for thin film deposition? Choose the Right Method for Your Application

- What is the effect of pressure and ion energy in the sputtering process? Optimize Film Density & Step Coverage

- What is the atomic layer deposition technique? Unlock Atomic-Level Precision for Your Thin Films

- What is the role of a CVD system in SiC coating fabrication? Achieve Precise Nanocrystalline Results