In short, KBr is used in FTIR sample preparation because it is transparent to infrared light. Potassium Bromide (KBr) acts as an inert, solid matrix that holds a powdered sample, allowing the instrument's IR beam to pass through and measure the sample's unique absorption spectrum without interference from the matrix itself.

The core challenge in analyzing a solid sample with FTIR is getting infrared light to pass through it cleanly. KBr solves this by serving as an invisible window—it dilutes the sample and presses it into a transparent disc, ensuring the only absorption spectrum detected belongs to the sample, not the material holding it.

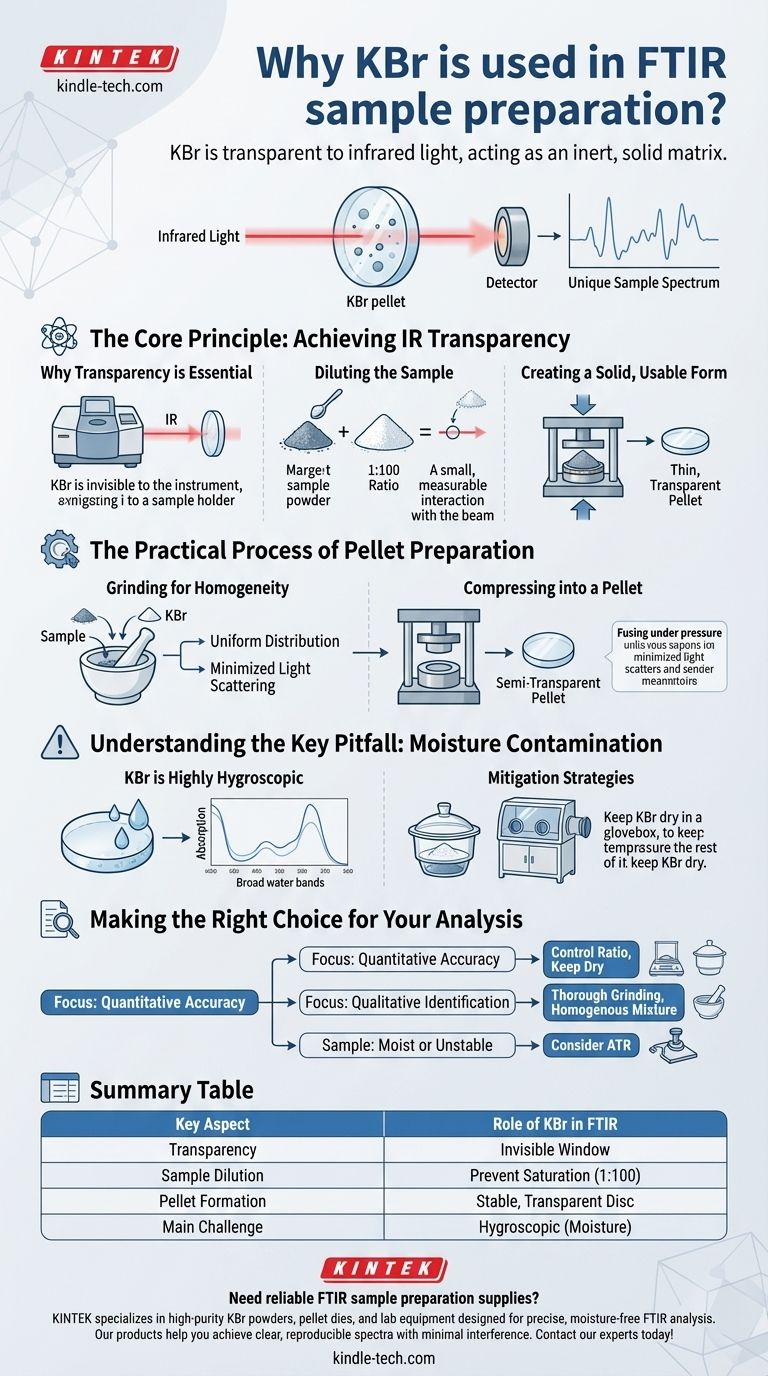

The Core Principle: Achieving IR Transparency

Why Transparency is Essential

The goal of FTIR spectroscopy is to measure how a sample absorbs infrared light at different wavelengths.

To get an accurate reading of the sample, the material used to hold it must not absorb infrared light in the same region. KBr is an ionic salt that lacks covalent bonds that absorb mid-infrared radiation, making it effectively invisible to the FTIR instrument.

Diluting the Sample for Accurate Measurement

Most solid samples, even as fine powders, are too concentrated and will absorb or scatter nearly all the IR light, saturating the detector and producing a useless spectrum.

The sample is mixed with KBr powder, typically at a 1:100 ratio. This dilution ensures that only a small, measurable amount of the sample interacts with the beam, resulting in a clean spectrum with distinct, quantifiable peaks.

Creating a Solid, Usable Form

KBr has the ideal physical property of being a soft crystalline solid that can be formed into a thin, transparent disc or "pellet" under high pressure.

This pellet is mechanically stable, easy to handle, and can be mounted directly in the spectrometer's sample holder, creating a consistent path for the IR beam to travel through.

The Practical Process of Pellet Preparation

Grinding for Homogeneity

The first step is to thoroughly grind the small amount of sample with the KBr powder, typically using an agate mortar and pestle.

This process is critical to reduce the sample's particle size below the wavelength of the IR light, which minimizes light scattering. It also ensures the sample is distributed uniformly throughout the KBr matrix, which is essential for a repeatable and representative measurement.

Compressing into a Pellet

The finely ground mixture is placed into a pellet die and compressed using a hydraulic press.

The intense pressure causes the KBr to flow and fuse, trapping the sample particles within a solid, salt-crystal lattice. The result is a semi-transparent pellet ready for analysis.

Understanding the Key Pitfall: Moisture Contamination

KBr is Highly Hygroscopic

The primary disadvantage of KBr is that it is hygroscopic, meaning it readily absorbs moisture from the atmosphere.

Water has very strong and broad absorption bands in the infrared spectrum. If the KBr absorbs water, these bands will appear in your spectrum and can easily obscure the peaks from your actual sample, leading to misinterpretation of the data.

Mitigation Strategies

To prevent moisture contamination, the KBr powder must be kept in a desiccator or dried in an oven before use.

In humid environments, the grinding and pressing process should ideally be performed inside a glovebox with a dry atmosphere or by using a specialized vacuum die that removes air and moisture during compression.

Making the Right Choice for Your Analysis

Preparing a high-quality KBr pellet is a foundational technique for analyzing solid samples. Success depends on careful attention to detail, particularly regarding dilution and moisture control.

- If your primary focus is quantitative accuracy: Meticulously control the sample-to-KBr ratio and prioritize keeping all components completely dry to avoid spectral interference from water.

- If your primary focus is qualitative identification: Ensure thorough grinding to achieve a homogenous mixture and a clear pellet, which will produce a clean spectrum with well-defined peaks.

- If your sample is inherently moist or unstable: Consider an alternative sampling method like Attenuated Total Reflectance (ATR), which analyzes the surface of a sample directly without pellet preparation.

Ultimately, mastering the KBr pellet technique provides a reliable and cost-effective method for obtaining high-quality FTIR spectra from a wide range of solid materials.

Summary Table:

| Key Aspect | Role of KBr in FTIR |

|---|---|

| Transparency | KBr is transparent to IR light, acting as an invisible window. |

| Sample Dilution | Dilutes sample (1:100 ratio) to prevent detector saturation. |

| Pellet Formation | Presses into a stable, transparent disc under high pressure. |

| Main Challenge | Hygroscopic—absorbs moisture, which can interfere with spectra. |

Need reliable FTIR sample preparation supplies? KINTEK specializes in high-purity KBr powders, pellet dies, and lab equipment designed for precise, moisture-free FTIR analysis. Our products help you achieve clear, reproducible spectra with minimal interference. Contact our experts today to find the right solution for your laboratory's needs!

Visual Guide

Related Products

- kbr pellet press 2t

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- How do you prepare a KBr pellet for IR spectroscopy? Master the Key Steps for a Clear Spectrum

- What is a KBr pellet? A Guide to Preparing Solid Samples for IR Spectroscopy

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis

- How much sample is needed for IR? Optimize Your Analysis with Minimal Material

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques