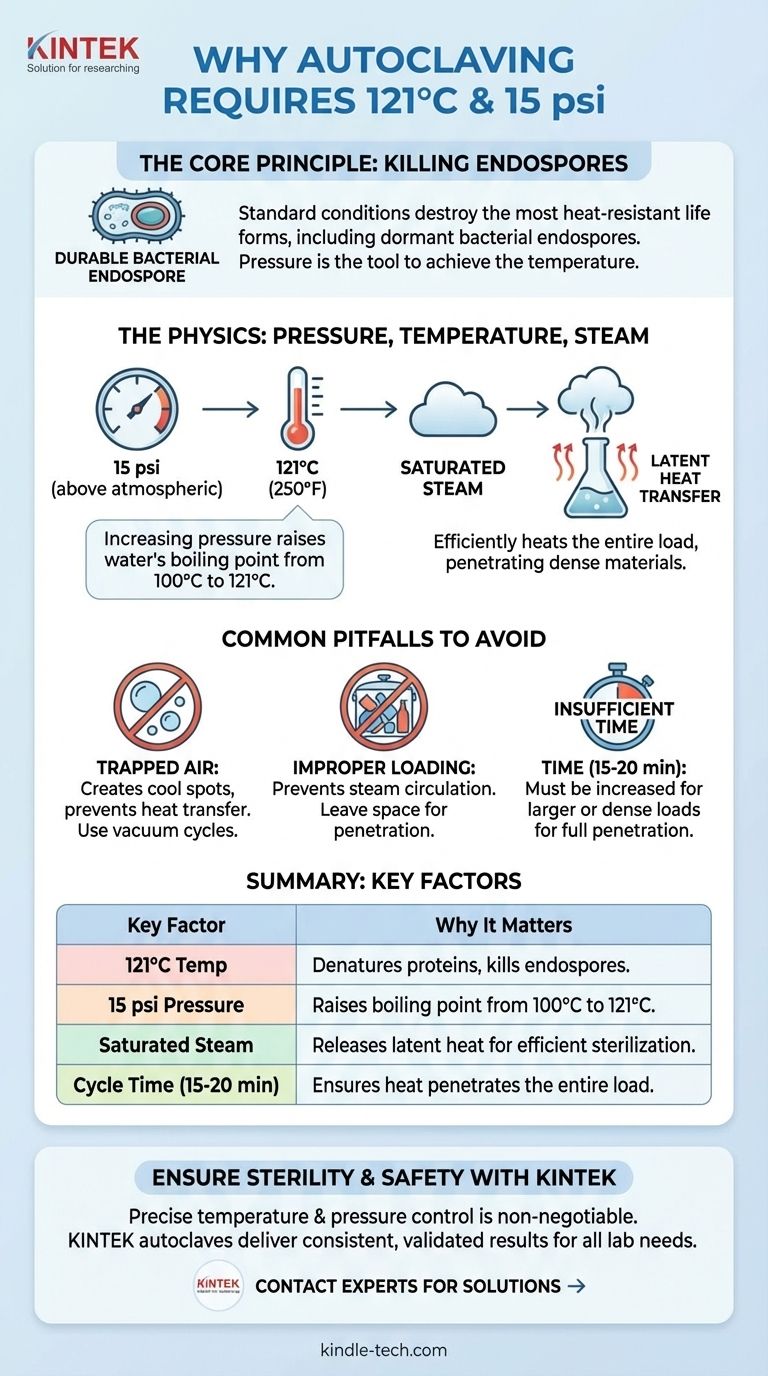

At its core, the standard of 121°C and 15 psi for autoclaving is the scientifically established condition required to kill the most heat-resistant life forms known to science: bacterial endospores. The pressure itself is not the sterilizing agent; it is simply the tool that allows water to be heated to 121°C, creating high-energy saturated steam that reliably destroys all microorganisms.

The critical insight is that pressure and temperature are linked. Increasing the pressure inside the autoclave to 15 psi above atmospheric pressure raises the boiling point of water from 100°C to 121°C, a temperature hot enough to guarantee the destruction of even the most resilient microbes.

The Physics Behind Sterilization: Temperature, Not Pressure

To understand why autoclaving works, we must first look at the relationship between pressure, water, and heat. The goal is to create an environment far more lethal to microbes than simple boiling water.

The Problem with Boiling Water

At standard atmospheric pressure, water boils at 100°C (212°F). While this temperature is sufficient to kill many bacteria and viruses, it is not hot enough to reliably destroy bacterial endospores.

Endospores are dormant, highly durable structures produced by certain bacteria. They can survive boiling water for extended periods, making 100°C an inadequate temperature for true sterilization.

How Pressure Elevates Boiling Point

An autoclave functions much like a sophisticated pressure cooker. By sealing the chamber and pumping in steam, it increases the internal pressure.

When pressure on a liquid increases, its boiling point also increases. At a pressure of 15 pounds per square inch (psi) above normal atmospheric pressure, the boiling point of water is raised to precisely 121°C (250°F).

Why 121°C is the Magic Number

This specific temperature was not chosen at random. Through extensive research, 121°C was determined to be the temperature required to effectively destroy the endospores of thermophilic (heat-loving) bacteria, such as Geobacillus stearothermophilus.

These spores are used as the benchmark for sterilization. If conditions are sufficient to kill them, it is assumed that all other, less-resistant organisms have also been eliminated. The heat at 121°C rapidly denatures essential proteins and enzymes within the microbes, causing irreversible damage and death.

The Critical Role of Steam Quality

The type of steam created is just as important as the temperature. Autoclaves rely on a specific state of steam to do their work effectively.

It's All About Saturated Steam

An autoclave is designed to produce saturated steam. This is steam that is in equilibrium with heated water at the same pressure, meaning it holds the maximum possible amount of water vapor for that temperature and pressure.

This is fundamentally different from dry, superheated steam, which is less effective at heat transfer for sterilization purposes.

The Power of Latent Heat Transfer

The true killing power of an autoclave comes from the massive energy transfer that occurs when saturated steam condenses.

When the 121°C steam comes into contact with a cooler item inside the chamber (e.g., glassware, media, or surgical tools), it instantly condenses back into a liquid. This phase change releases a large amount of energy, known as latent heat, directly onto the item's surface.

This process is incredibly efficient at heating the entire load to the target temperature and allowing the heat to penetrate dense or porous materials, ensuring complete sterilization.

Common Pitfalls to Avoid

Achieving the correct temperature and pressure is not enough. Several factors can lead to a failed sterilization cycle, compromising the entire process.

Trapped Air

Air is the enemy of autoclaving. If air is not completely purged from the chamber, it creates "cool spots" because a pocket of hot air transfers heat far less effectively than saturated steam.

This is the most common cause of sterilization failure. Modern autoclaves use vacuum cycles or gravity displacement methods to ensure all air is removed before the sterilization phase begins.

Improper Loading

Overloading the autoclave or packing items too tightly prevents steam from circulating freely. Steam must be able to contact every surface of every item in the load.

Leaving space between items is critical for allowing proper steam penetration and ensuring no part of the load is shielded from the sterilizing agent.

Insufficient Time

Time is the third critical parameter, alongside temperature and pressure. A typical cycle holds the load at 121°C and 15 psi for at least 15-20 minutes.

However, this duration must be increased for larger or denser loads to ensure the heat has enough time to fully penetrate to the center of the items being sterilized.

Making the Right Choice for Your Goal

Understanding these principles ensures you are not just running a machine, but controlling a scientific process.

- If your primary focus is routine sterilization of liquids and glassware: Adhere strictly to the standard 121°C, 15 psi, and 15-20 minute cycle, but prioritize proper loading to guarantee steam circulation.

- If your primary focus is sterilizing dense or porous loads (like animal bedding or waste): Use longer cycle times and verify that your autoclave's pre-cycle vacuum effectively removes all trapped air.

- If your primary focus is quality control and validation: Regularly use biological indicators containing Geobacillus stearothermophilus spores to confirm that your cycles are achieving complete sterilization, not just reaching the right numbers on the gauge.

Mastering these fundamental principles ensures the absolute sterility and safety of your materials.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| 121°C Temperature | Required to denature proteins and destroy the most heat-resistant bacterial endospores. |

| 15 psi Pressure | Raises the boiling point of water from 100°C to 121°C, enabling the critical temperature. |

| Saturated Steam | Condenses on cool surfaces, releasing latent heat for efficient and penetrating sterilization. |

| Cycle Time (15-20 min) | Ensures heat has sufficient time to penetrate the entire load for complete sterility. |

Ensure your lab's sterility and safety with reliable autoclaves from KINTEK.

Precise temperature and pressure control is non-negotiable for effective sterilization. Whether you're processing liquids, glassware, or dense materials, KINTEK's autoclaves are engineered to deliver consistent, validated results cycle after cycle.

We specialize in lab equipment that meets the rigorous demands of research and healthcare. Let us help you achieve guaranteed sterility and protect your work.

Contact our experts today to find the perfect autoclave solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the temperature of autoclave in microbiology lab? Achieve Sterile Conditions with 121°C

- Where should an autoclave be located in a lab? Balance Safety and Efficiency for Optimal Workflow

- What is autoclave in laboratory? Achieve Total Sterility for Your Lab

- What are the advantages of using an autoclave in the lab? Achieve Unmatched Sterilization for Your Lab

- What is the maximum pressure for autoclave? It's Not About Maximum Pressure, It's About Precise Sterilization