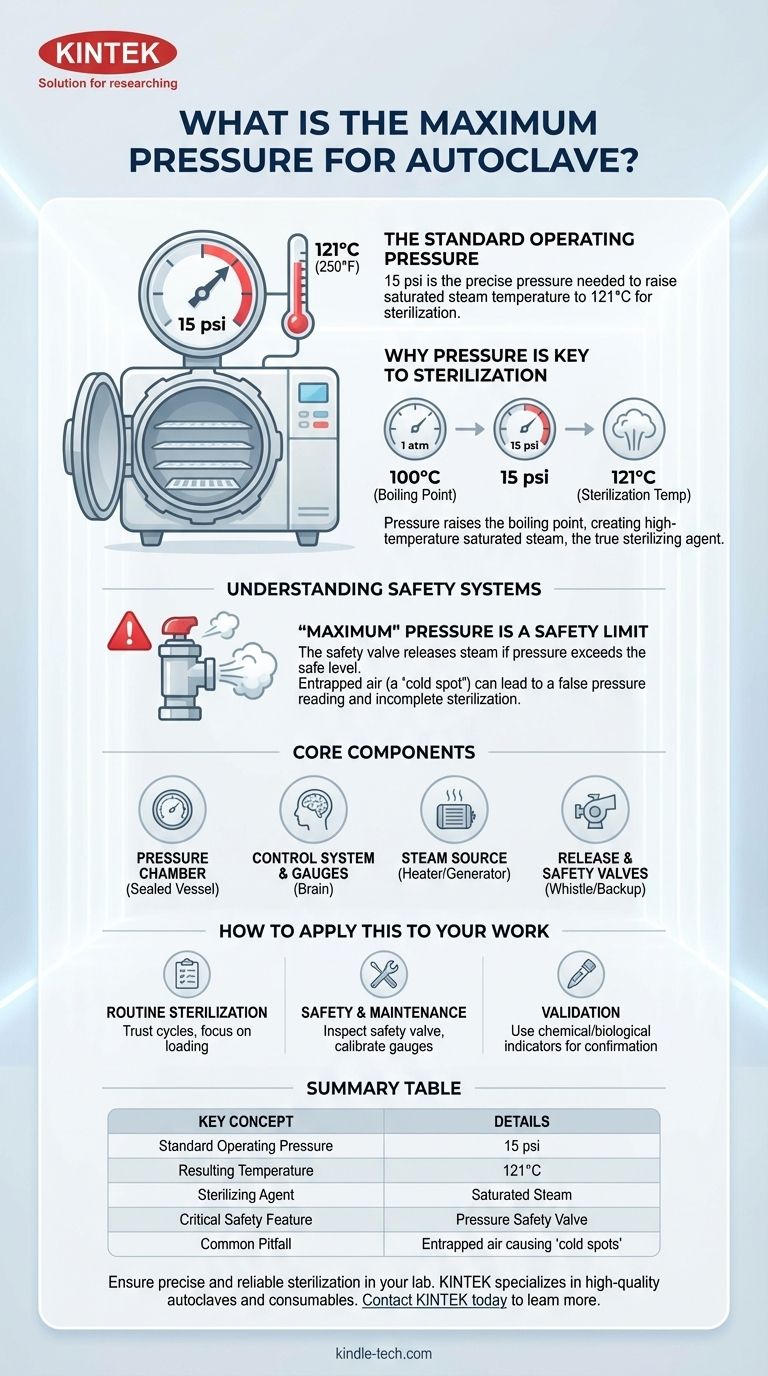

The standard operating pressure for most laboratory and medical autoclaves is approximately 15 pounds per square inch (psi) above atmospheric pressure. This specific pressure is not an arbitrary limit but is the precise level required to raise the temperature of saturated steam to 121°C (250°F). The concept of a universal "maximum" pressure is a function of individual machine design and its safety systems, not a standard operational setting.

The critical insight is that autoclave operation is not about maximizing pressure. It is about using a precise, standardized pressure (15 psi) as a tool to achieve the consistent, high-temperature steam (121°C) required for effective sterilization.

Why Pressure Is the Key to Sterilization

To properly use an autoclave, it's essential to understand that pressure is the means, not the end. The true sterilizing agent is the high-temperature saturated steam, and pressure is simply the method for creating it.

It's Not About Pressure, It's About Temperature

At normal atmospheric pressure, water boils at 100°C (212°F). This is not hot enough to reliably kill all microbial life, particularly resilient bacterial spores.

By increasing the pressure inside a sealed chamber, we can raise the boiling point of water. The relationship between pressure and temperature is a fundamental principle of physics.

The Role of Saturated Steam

At approximately 15 psi (103 kPa or 1.1 kg/cm²) above atmospheric pressure, the boiling point of water is driven up to 121°C (250°F).

When water boils at this temperature, it creates saturated steam. This type of steam is extremely effective at transferring thermal energy to every surface it touches, ensuring rapid and thorough heat penetration for sterilization.

The Standard Operating Condition

The combination of 15 psi, 121°C, and a set duration (typically 15 to 60 minutes), depending on the load, forms the universally recognized standard for steam sterilization. Most autoclaves are specifically calibrated to achieve and maintain this state.

Understanding the Safety Systems and Pitfalls

The question of "maximum" pressure is really a question about safety limits and operational failures. Your autoclave is engineered to operate at a specific pressure, and its safety features are designed to prevent it from exceeding that level.

The "Maximum" Pressure Is a Safety Limit

Every autoclave is built with a pressure chamber or vessel rated for a pressure significantly higher than its normal operating level. However, the functional maximum is determined by its safety mechanisms.

A safety valve is a critical, non-negotiable component. This mechanical device is spring-loaded to automatically open and vent steam if the chamber pressure exceeds a predetermined safe level, preventing a catastrophic failure.

The Risk of Entrapped Air

A common and critical mistake is assuming the pressure gauge reading tells the whole story. If air is not properly purged from the chamber at the beginning of a cycle, it becomes trapped.

This trapped air contributes to the total pressure reading on the gauge, but it does not contribute to the temperature. This dangerous scenario, known as a "cold spot," means the gauge might read 15 psi, but the actual steam temperature is well below the required 121°C, leading to incomplete sterilization.

The Core Components Enabling Pressurization

Several key components work in concert to create and control the high-pressure steam environment.

The Pressure Chamber

This is the sealed vessel, often with inner and outer walls, designed to safely contain the high-pressure steam.

The Control System and Gauges

This is the brain of the autoclave, managing the heating elements and valves to achieve and maintain the target pressure. The pressure gauge provides a visual confirmation of the internal state.

The Steam Source

Some autoclaves have a built-in electric heater or steam generator to boil water within the unit. Others are connected to an external source of facility steam.

The Release and Safety Valves

The pressure release valve (or "whistle" on simpler models) is used to vent pressure at the end of a cycle. The safety valve is the emergency backup that prevents over-pressurization.

How to Apply This to Your Work

Your focus should not be on pushing pressure limits, but on ensuring the standard conditions for sterilization are met reliably and safely.

- If your primary focus is routine sterilization: Trust your autoclave's pre-programmed cycles. Concentrate on properly loading the machine to allow for steam circulation and air removal, rather than worrying about the pressure settings.

- If your primary focus is safety and maintenance: Regularly inspect the safety valve and ensure pressure gauges are calibrated. Be familiar with the normal operating sounds and readings of your specific unit to quickly identify anomalies.

- If your primary focus is validating a sterilization cycle: Rely on chemical or biological indicators placed within the load. These tools verify that the required temperature and steam penetration were achieved, which is a more accurate measure of success than a pressure reading alone.

Ultimately, understanding that pressure is the means to an end—reliable, high-temperature sterilization—is the key to operating any autoclave with confidence and precision.

Summary Table:

| Key Concept | Details |

|---|---|

| Standard Operating Pressure | 15 psi (above atmospheric pressure) |

| Resulting Temperature | 121°C (250°F) |

| Sterilizing Agent | Saturated Steam |

| Critical Safety Feature | Pressure Safety Valve |

| Common Pitfall | Entrapped air causing 'cold spots' |

Ensure precise and reliable sterilization in your lab.

Understanding the relationship between pressure and temperature is critical for effective autoclave operation. KINTEK specializes in providing high-quality laboratory autoclaves and consumables designed for safety, accuracy, and consistent performance.

Let our experts help you select the right equipment to meet your specific sterilization needs. Contact KINTEK today to learn how our solutions can enhance your lab's efficiency and safety.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Are there any specific types of contamination that an autoclave cannot remove? Understanding the Limits of Steam

- When can autoclave be used? Achieve Absolute Sterility for Your Lab and Medical Equipment

- Why is zirconium preferred as a lining material for HPAL autoclaves? Ensure Unmatched Corrosion Resistance

- What is the function of a High-Pressure Hydrothermal Autoclave in preparing mesoporous hydroxyapatite? Key Insights

- How do you use an autoclave in a microbiology lab? Master Sterilization for Lab Safety & Accuracy

- Is autoclave a lab equipment? Essential Sterilization for Reliable Science

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- When should you replace an autoclave? A guide to ensure safety, efficiency, and compliance.