No, a PVD coating itself does not tarnish. Tarnishing is a specific chemical reaction that affects certain metals, and the materials used in PVD coatings are chemically inert and non-reactive. A PVD finish acts as a durable, protective barrier that seals the underlying base metal, preventing it from coming into contact with the elements that would cause it to tarnish or corrode.

The core issue with PVD is not a risk of tarnishing, but rather the long-term physical durability of the coating. While the PVD layer itself is chemically stable, its lifespan is determined by how well it resists physical abrasion and scratches that could eventually expose the base metal underneath.

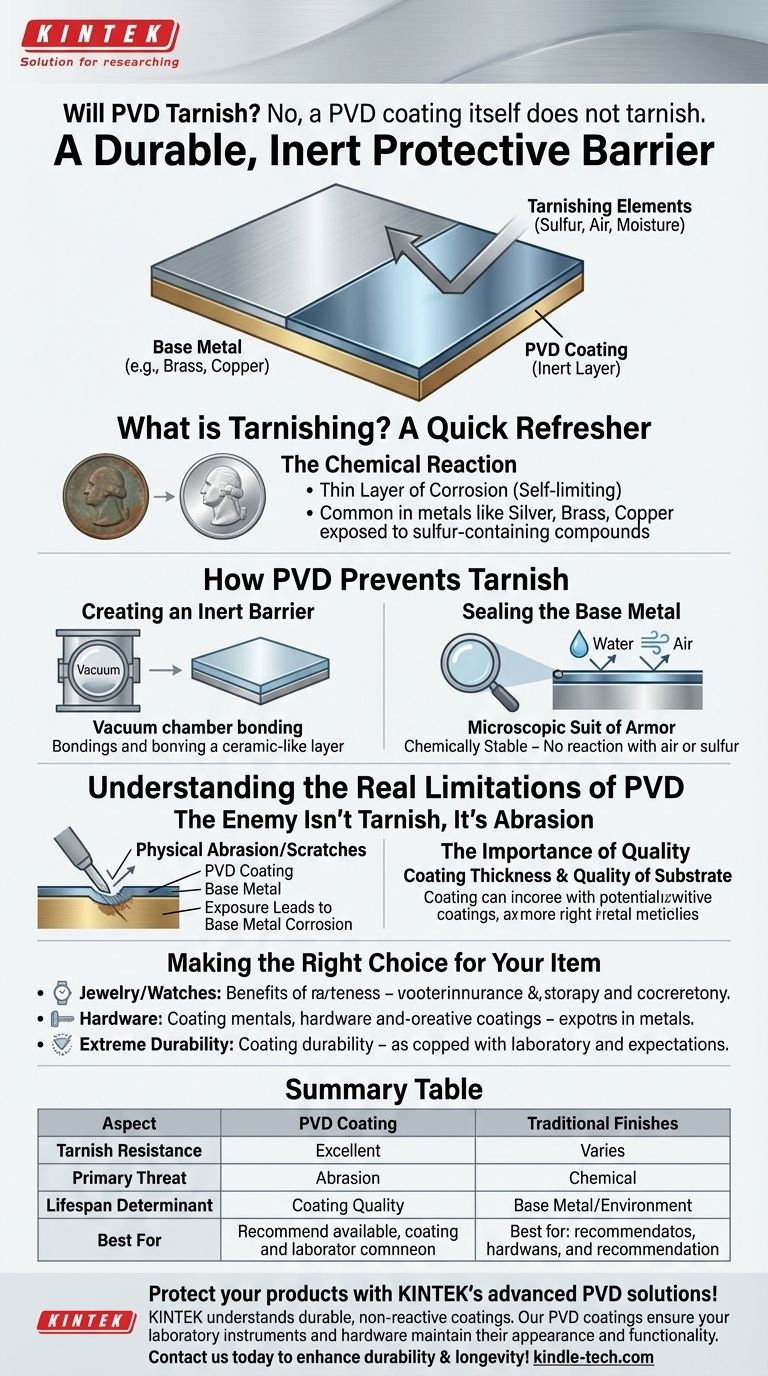

What is Tarnishing? A Quick Refresher

The Chemical Reaction of Tarnish

Tarnish is a thin layer of corrosion that forms on the outermost surface of certain metals as they undergo a chemical reaction. It's not rust, but a self-limiting layer that often appears as a dull gray or black film.

Why Some Metals Are Prone to It

This reaction is most common in metals like silver, brass, and copper when they are exposed to sulfur-containing compounds in the atmosphere. The metal's surface reacts with these elements, changing its color and losing its luster.

How PVD Prevents Tarnish

Creating an Inert Barrier

Physical Vapor Deposition (PVD) is a process that bonds a very thin layer of a hard, ceramic-like material (such as titanium nitride or zirconium nitride) to a base metal in a vacuum. This process creates a new, integrated surface layer.

Sealing the Base Metal

This PVD layer acts as a microscopic suit of armor for the product. It physically blocks the base metal from being exposed to air, moisture, skin oils, and chemicals that would otherwise cause it to tarnish.

The Coating Itself is Chemically Stable

The materials used for PVD coatings are chosen for their extreme hardness and chemical stability. They do not react with sulfur or oxygen in the air, meaning the PVD surface itself is incapable of tarnishing.

Understanding the Real Limitations of PVD

The Enemy Isn't Tarnish, It's Abrasion

The primary threat to a PVD finish is not chemical but physical. While incredibly durable and more scratch-resistant than traditional plating, a PVD coating can be worn down or scratched off over a long period of heavy use.

Exposing the Base Metal

If a deep scratch or significant abrasion manages to penetrate the PVD layer, the base metal underneath will be exposed. If that base metal (like stainless steel or brass) is susceptible to corrosion or tarnish, it can then begin to degrade in that specific spot.

The Importance of Quality

The durability of a PVD finish is not universal. It depends heavily on the thickness of the coating, the quality of the substrate preparation, and the specific materials used. A well-executed PVD application from a reputable brand will last significantly longer than a cheap, thinly applied coating.

Making the Right Choice for Your Item

When evaluating a PVD-coated product, shift your thinking from "Will it tarnish?" to "How will I use it?".

- If your primary focus is daily wear jewelry or watches: PVD is a superior choice for preventing tarnish and discoloration, but expect that high-contact points (like a bracelet clasp) may show signs of physical wear after many years.

- If your primary focus is hardware like faucets or fixtures: PVD is an excellent, low-maintenance option that will resist tarnish and corrosion from humidity and cleaning products far better than traditional finishes.

- If you are concerned about extreme durability and scratches: Look for products with a high-quality base metal (like 316L stainless steel) and a thick PVD coating from a brand known for its quality control.

Ultimately, PVD is best understood as a highly advanced protective finish that provides exceptional resistance to the chemical reaction of tarnishing.

Summary Table:

| Aspect | PVD Coating | Traditional Finishes |

|---|---|---|

| Tarnish Resistance | Excellent (Chemically inert) | Varies (Often prone) |

| Primary Threat | Physical abrasion/scratches | Chemical reactions (tarnish/corrosion) |

| Lifespan Determinant | Coating thickness & quality | Base metal & environmental exposure |

| Best For | Jewelry, watches, hardware in humid environments | Items with minimal exposure to elements |

Protect your products with KINTEK's advanced PVD solutions!

As specialists in lab equipment and consumables, KINTEK understands the need for durable, non-reactive coatings that withstand demanding environments. Our high-quality PVD coatings provide an inert barrier against tarnish and corrosion, ensuring your laboratory instruments and hardware maintain their appearance and functionality over time.

Contact us today to learn how our PVD expertise can enhance the durability and longevity of your products!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer