Table of Contents

Introduction to Rotary Furnace Technology

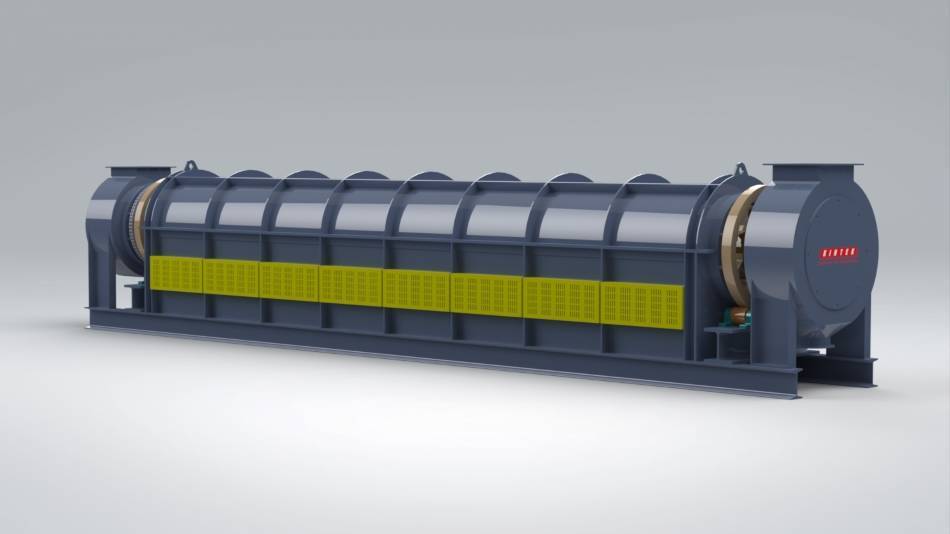

Rotary furnaces are widely used in various industries for continuous thermal processing of materials at elevated temperatures. These furnaces offer advantages over other types of furnaces due to their ability to handle large volumes of material and provide uniform heating. In this article, we delve into the intricacies of rotary furnace technology, exploring design improvements and their impact on efficient material processing. We will discuss specific advancements in mixing and conveying technologies, tilting mechanisms, fuel options, and refractory lining materials. By understanding these design considerations, industries can optimize their rotary furnace performance, resulting in improved throughput, energy efficiency, and product quality.

Design Advancements for Enhanced Performance

Mixing and Conveying Technologies

Mixing technologies can significantly improve the performance of rotary furnaces by increasing the volume utilization. This is particularly beneficial in processes where the reaction time is limited by heat or mass transfer. By reducing the time requirement, mixing technologies enable the use of smaller furnaces that meet the same process requirements.

One common approach to mixing in rotary furnaces involves the use of screw conveyors or threaded rods. This design allows for controlled mixing of the material as it moves through the furnace. Another configuration utilizes a reverberating design, where the material is shaken down the tube to promote mixing.

For applications involving the extraction of metals from ores, rotary furnaces can be modified with a tilt mechanism. This allows liquid metal to drain from the reactor, facilitating the separation of the metal from the ore.

These advancements in mixing and conveying technologies have significantly enhanced the capabilities of rotary furnaces, enabling them to handle a wider range of materials and processes with improved efficiency and productivity.

Mixing and Conveying Innovations

Mixing and conveying technologies play a pivotal role in enhancing the processing environment and ensuring the homogeneity of materials. These technologies offer several advantages that contribute to improved efficiency and product quality.

Promoting Material Homogeneity:

Mixing technologies ensure the uniform distribution of components within a mixture. This is crucial for processes that require precise control over the composition and properties of the final product. By eliminating variations in material composition, mixing technologies reduce the risk of defects and increase the consistency of the finished product.

Preventing Unwanted Axial Mixing:

Unwanted axial mixing can occur when materials move along the length of a processing vessel, resulting in non-uniformity. Conveying technologies address this issue by controlling the movement of materials, preventing axial mixing, and maintaining the desired homogeneity throughout the process.

Improved Heat and Mass Transfer:

Mixing and conveying technologies facilitate efficient heat and mass transfer within the processing environment. By promoting uniform mixing, these technologies enhance the contact between reactants, catalysts, and other process components. This improved contact accelerates reactions and increases the efficiency of the process.

Reduced Cycle Times and Improved Productivity:

Optimized mixing and conveying systems can significantly reduce cycle times by ensuring that materials are processed efficiently. By eliminating bottlenecks and minimizing downtime, these technologies increase productivity and throughput, leading to higher production capacity.

Enhanced Product Quality:

The combination of improved material homogeneity, controlled mixing, and efficient heat and mass transfer contributes to enhanced product quality. By eliminating defects, ensuring uniform composition, and maintaining the desired material properties, mixing and conveying technologies play a vital role in producing high-quality products that meet industry standards.

Benefits of Tilting Rotary Furnaces

Tilting rotary furnaces provide numerous advantages over conventional static rotary furnaces, including:

Reduced Cycle Times

Tilting furnaces allow for faster cycle times by eliminating the need to manually tilt the furnace to pour molten metal into molds. This automation reduces labor requirements and increases productivity.

Increased Throughput

The ability to tilt the furnace quickly and efficiently enables operators to fill multiple molds in a shorter period of time. This increased throughput leads to higher production rates and improved overall efficiency.

Efficient Energy Utilization

Tilting rotary furnaces utilize energy more efficiently compared to static furnaces. The ability to tilt the furnace allows for better control of the molten metal flow, minimizing heat loss and reducing energy consumption.

Other Advantages

In addition to these primary benefits, tilting rotary furnaces also offer the following advantages:

- Improved safety by reducing the risk of spills and accidents during pouring

- Increased flexibility in mold placement and orientation

- Reduced labor costs due to automated tilting mechanisms

- Enhanced product quality due to improved molten metal distribution and temperature control

- Environmentally friendly operation with reduced emissions and energy consumption

Overall, tilting rotary furnaces provide a range of benefits that make them a valuable asset for foundries and other industries requiring efficient and productive metal melting and casting processes.

Fuel Options and Lining Materials

Rotary furnaces utilize various fuel options to generate heat, including:

Gas: Natural gas is a commonly used fuel due to its availability, cost-effectiveness, and clean-burning properties.

Diesel: Diesel fuel provides higher energy density compared to gas but may emit more pollutants.

Furnace Oil: Furnace oil, a heavy fuel, offers high thermal efficiency and is suitable for applications requiring extreme temperatures.

The choice of fuel depends on factors such as availability, cost, environmental regulations, and furnace design.

Importance of Refractory Lining Materials:

Refractory lining materials are crucial for furnace efficiency and longevity. They serve as a barrier between the molten material and the furnace structure, protecting it from extreme heat, chemical reactions, and abrasion.

Types of Refractory Lining:

- Bricks: Durable and high-temperature resistant, but may require skilled installation.

- Cement: Provides a monolithic lining, offering flexibility and ease of installation.

- Moldable: Versatile and customizable, used for complex shapes or repairs.

Benefits of Refractory Lining:

- Insulation: Maintains furnace temperature, reducing energy consumption.

- Corrosion Protection: Prevents chemical reactions between molten material and furnace structure.

- Thermal Shock Resistance: Withstands rapid temperature changes, extending furnace lifespan.

- Environmental Protection: Minimizes emissions and improves air quality.

Factors Affecting Refractory Lining Life:

- Type of refractory material

- Furnace operating temperature

- Frequency of alloy changes

- Cooling and heating cycles

By selecting appropriate fuel options and employing high-quality refractory lining materials, the efficiency, longevity, and safety of rotary furnaces can be significantly enhanced.

Industrial Applications of Rotary Furnaces

Rotary furnaces are versatile industrial heating systems utilized in various sectors. Their applications range from metalworking to material processing, showcasing their adaptability and efficiency.

Metalworking

- Forging: Rotary furnaces provide precise temperature control and uniform heating, making them ideal for forging processes.

- Aluminum Melting: Rotary melting furnaces are highly efficient for recycling aluminum scrap, effectively recovering all forms of scrap.

Material Processing

- Ceramic Doping: Rotary furnaces enable the doping of ceramics with rare earth metals, modifying their properties for specialized applications.

- Calcining: Rotary tube furnaces are designed for continuous throughput of loose materials, making them suitable for calcining processes.

- Oxidation: Rotary tube furnaces facilitate the oxidation of materials, enhancing their properties and enabling chemical reactions.

- Roasting: Rotary tube furnaces are employed in roasting processes, influencing phase transitions and altering material compositions.

Advantages of Rotary Furnaces

Rotary furnaces offer numerous advantages, including:

- Temperature Uniformity: High-quality heating elements ensure excellent temperature uniformity, resulting in consistent material processing.

- Continuous Processing: Rotary tube furnaces are designed for continuous material processing, increasing efficiency and productivity.

- Versatile Applications: Rotary furnaces cater to a wide range of industries and applications, demonstrating their versatility and adaptability.

Optimizing Temperature Uniformity

In rotary furnaces, temperature uniformity is paramount, as it directly affects the quality and consistency of the processed materials.

High-quality heating elements play a crucial role in achieving optimal temperature uniformity. These elements ensure even heat distribution throughout the furnace chamber, minimizing temperature variations and providing precise control over the heating process.

The continuous rotation of the sample within the furnace further enhances temperature uniformity. As the sample moves through the hot furnace, all surfaces are exposed to the consistent temperature profile, resulting in uniform heating and improved product homogeneity.

By utilizing high-quality heating elements and the continuous rotation of the sample, rotary furnaces offer exceptional temperature uniformity, ensuring consistent material properties and enhanced product quality.

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Rotary Furnaces: A Comprehensive Guide to Advanced Materials Processing

- What is activated carbon regeneration Rotary Furnace

- Rotary Furnaces: Advanced Materials Processing and Applications

- Electric Rotary Kiln Pyrolysis Furnace: Design, Operation, and Applications

- Exploring the Benefits and Applications of Rotary Furnaces: A Comprehensive Guide