Overview of Isostatic Pressing

Table of Contents

- Overview of Isostatic Pressing

- Cold Isostatic Pressing (CIP) vs Hot Isostatic Pressing (HIP)

- Comparison of cold and hot isostatic pressing

- Explanation of the use of cold isostatic pressing (CIP) in compacting green parts at ambient temperatures

- Description of hot isostatic pressing (HIP) in fully consolidating parts at high temperatures and its role in eliminating residual porosity from a sintered PM part

- Advantages and Applications of Cold Isostatic Pressing (CIP)

- Benefits of cold isostatic pressing especially for large or complex compacts

- Range of materials that can be pressed isostatically including metals, ceramics, plastics, and composites

- Details on the pressures required for compacting in cold isostatic pressing

- Use of elastomeric molds in the wet or dry bag process in cold isostatic pressing

Definition and importance of isostatic pressing in powder metallurgy

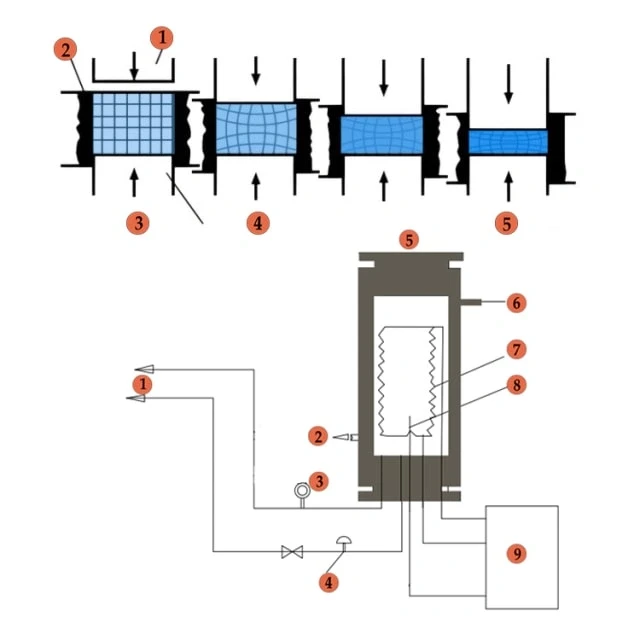

Isostatic pressing is a powder processing technique that uses fluid pressure to compact the part. It involves placing metal powders in a flexible container, which acts as a mold for the part. Fluid pressure is exerted over the entire outside surface of the container, causing the powder to be formed into the desired geometry. Unlike other processes that exert force on the powder through an axis, isostatic pressing applies pressure equally from all directions.

Isostatic pressing is widely used in the manufacturing industry for its ability to produce materials with high and uniform density. This process is especially beneficial for parts that are larger, have high thickness to diameter ratios, or require superior material properties. It allows for the production of complex shapes and precise tolerances, reducing the need for costly machining. Isostatic pressing is commonly used in the consolidation of powders and the defect healing of castings in various industries, including ceramics, metals, composites, plastics, and carbon.

Understanding the uniformity of density and microstructure achieved through isostatic pressing

Isostatic pressing ensures the uniform compaction of the powder and uniform density within the compacted part. The all-around pressure exerted by the fluid during the pressing process eliminates density variations that are often a concern in conventional processing methods. The use of a flexible membrane or hermetic container as a pressure barrier between the powder and the pressurizing medium (liquid or gas) ensures that the pressure is applied equally from all directions.

The uniform density achieved through isostatic pressing is highly desirable for various applications. It allows for consistent material properties and performance, ensuring reliable and high-quality products. Additionally, the elimination of porosity in the powder mixture results in improved mechanical strength and structural integrity.

Isostatic pressing offers several advantages over other manufacturing techniques. It allows for the compaction of powder with the same pressure in all directions, leading to high and uniform density. This process also removes many of the constraints that limit the geometry of parts compacted unidirectionally in rigid dies. Isostatic pressing is particularly suitable for difficult-to-compact and expensive materials, such as superalloys, titanium, tool steels, stainless steel, and beryllium, as it ensures highly efficient material utilization.

Cold Isostatic Pressing (CIP) vs Hot Isostatic Pressing (HIP)

Comparison of cold and hot isostatic pressing

In the realm of materials processing, two powerful techniques stand out: Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP). While both methods share the goal of enhancing material properties, they do so under different conditions, each offering unique advantages.

Cold Isostatic Pressing (CIP) involves subjecting a material to uniform pressure from all sides. This is achieved by immersing the material in a high-pressure fluid medium and applying hydraulic pressure. CIP is particularly effective for shaping and consolidating powdered materials, creating intricate shapes, and achieving high green density.

Hot Isostatic Pressing (HIP), on the other hand, takes the process a step further by combining high pressure with elevated temperatures. This method subjects a material to simultaneous high pressure and high temperature within a high-pressure chamber. HIP is used to densify materials, eliminate defects, and enhance properties through diffusion and consolidation. It's especially valuable for materials requiring improved structural integrity, reduced porosity, and higher mechanical properties.

Explanation of the use of cold isostatic pressing (CIP) in compacting green parts at ambient temperatures

Cold Isostatic Pressing (CIP) is a method of compacting powdered materials into a solid homogeneous mass before machining or sintering. CIP involves cold compaction using isostatic pressure, where the powder is subjected to equal pressure from all directions. This method is particularly useful for shaping and initial consolidation of powdered materials. It is commonly used for parts that are too large to be pressed in uniaxial presses and do not require high precision in the sintered state. CIP is also known as hydrostatic pressing and is a simple process capable of producing high-integrity billets or preforms with minimal distortion or cracking when fired.

Description of hot isostatic pressing (HIP) in fully consolidating parts at high temperatures and its role in eliminating residual porosity from a sintered PM part

Hot Isostatic Pressing (HIP) is a process that consolidates material and closes pores within parts through the application of heat and pressure. It can be applied to many different materials, including metals and ceramics. HIP is used to fully consolidate parts at elevated temperatures by solid-state diffusion. This method combines high pressure and high temperature within a high-pressure chamber to achieve densification and enhanced properties.

HIP is particularly effective in eliminating residual porosity from a sintered powder metallurgy (PM) part. It improves part density, ductility, fatigue resistance, and other material properties. HIP can also include post-processing steps such as quenching and aging to further enhance the material's performance.

Hot Isostatic Pressing (HIP) has been used for decades to consolidate metal powders and metal matrix composites, produce fully dense components, eliminate porosity in sintered parts, produce metal-clad parts through diffusion bonding, and eliminate defects in castings. In recent years, HIP has also played a crucial role in assuring and increasing the quality of critical components produced by powder-based Additive Manufacturing.

Overall, Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) are two powder metallurgy techniques used to produce dense and high-quality metal components. CIP is ideal for shaping and initial consolidation, while HIP is favored for achieving fully consolidated parts with improved properties and reduced porosity.

Advantages and Applications of Cold Isostatic Pressing (CIP)

Benefits of cold isostatic pressing especially for large or complex compacts

Cold isostatic pressing (CIP) offers several advantages, particularly for the production of large or complex compacts. Unlike traditional pressing methods that require expensive dies, CIP allows for the production of parts without the high initial cost of pressing dies. This makes it a cost-effective option for manufacturing parts where the high cost of dies cannot be justified. Additionally, CIP enables the production of very large or complex compacts that may not be possible with other pressing methods.

Range of materials that can be pressed isostatically including metals, ceramics, plastics, and composites

CIP is a versatile process that can be used to press a wide range of materials, including metals, ceramics, plastics, and composites. This makes it suitable for various industries and applications. Whether you need to produce metal components, ceramic parts, or plastic products, CIP can accommodate different material types and provide high-quality compacts.

Details on the pressures required for compacting in cold isostatic pressing

The pressures required for compacting in cold isostatic pressing can vary depending on the specific material and application. Generally, pressures range from less than 5,000 psi to more than 100,000 psi (34.5 to 690 MPa). The high pressure applied during the CIP process helps to achieve uniform compaction and density in the final product. This results in parts with predictable shrinkage during subsequent processes, such as sintering.

Use of elastomeric molds in the wet or dry bag process in cold isostatic pressing

In cold isostatic pressing, powders are compacted by enclosing them in an elastomeric mold. Elastomeric molds, typically made of materials like polyurethane, rubber, or polyvinyl chloride (PVC), have low resistance to deformation. This allows the mold to be uniformly compressed when liquid pressure is applied.

There are two types of cold isostatic pressing processes: wet bag and dry bag. In the wet bag process, the elastomeric mold is removed and refilled after each pressure cycle. This method is suitable for compaction of large and complicated parts. On the other hand, the dry bag method involves using an integral mold that is part of the vessel. This method is used for simpler and smaller parts.

Overall, cold isostatic pressing is a versatile and cost-effective method for producing large or complex compacts in various materials. Its advantages, such as the ability to accommodate different material types and produce uniform density products, make it a viable option for industries ranging from aerospace to automotive.

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Isostatic Molding Pressing Molds for Lab

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Button Battery Storage Box for Battery Lab