Articles

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

8 months agoExplore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.

Learn More

Performance and application of polytetrafluoroethylene (PTFE) in high temperature environment

8 months ago

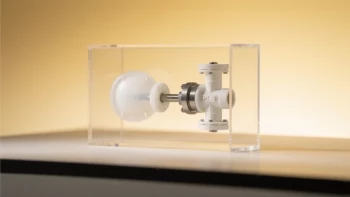

PTFE seals: the invisible guardian of industrial leakage prevention

8 months agoPTFE Seals are used to prevent liquid or gas leakage and are widely used in valves, pumps, and piping systems.

Learn More

PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

8 months agoThe unique advantages of polytetrafluoroethylene (PTFE) in high temperature and corrosion resistance analyze why it has become an indispensable material in industry, especially in applications in harsh environments.

Learn More

Innovative Application of PTFE in Mechanical Seals

8 months agoPTFE has become one of the core materials in the field of mechanical seals due to its unique chemical stability, low friction coefficient (0.04-0.15), wide temperature range (-268°C to +315°C) and excellent corrosion resistance (pH 0-14).

Learn More

The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

8 months agoFrom high-purity gas delivery pipelines to precision electrical insulation components, the multi-faceted application of PTFE in the semiconductor industry chain provides important guarantees for the purity, stability and reliability of the manufacturing process.

Learn More

How to use PTFE to improve the working efficiency of pumps and valves

8 months agoPolytetrafluoroethylene (PTFE) has become a key material for improving the efficiency of pumps and valves due to its unique physical and chemical properties.

Learn More

PTFE gasket: an all-around solution for flange sealing

8 months agoPolytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

Learn More

Development and Principles of Frozen Tissue Crushers

9 months agoExplore the history, classification, and principles of frozen tissue crushers, including grinding ball selection and how to choose the right crusher.

Learn More

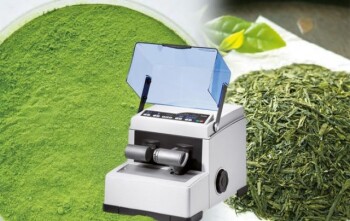

Application of Ultra-Micro Pulverization Technology in the Food Industry

9 months agoExplores the benefits and applications of ultra-micro pulverization technology in enhancing food processing and nutrient absorption.

Learn More

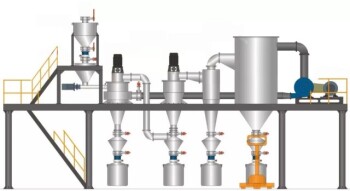

Cryogenic Pulverization Technology and Its Applications

9 months agoExplores the process, advantages, disadvantages, and applications of cryogenic pulverization in various fields.

Learn More

Application of Liquid Nitrogen in Food Freezing

9 months agoExplores the use of liquid nitrogen in food freezing, its advantages, methods, equipment, and safety considerations.

Learn More

Application of Low-Temperature Pulverization Technology in the Spice Industry

9 months agoExplores the benefits of low-temperature pulverization for maintaining spice quality and efficiency.

Learn More

10 Common Dry Ultrafine Crushing Processes

9 months agoOverview of various dry ultrafine crushing methods and their components.

Learn More

Techniques and Methods of Freeze Pulverization for Powdered Rubber

9 months agoAn overview of various methods for producing powdered rubber through freeze pulverization, including liquid nitrogen and air turbine expander cold methods.

Learn More

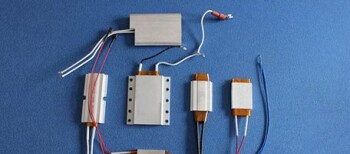

Precision Ceramic Materials for Energy Conversion Applications

9 months agoOverview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Learn More

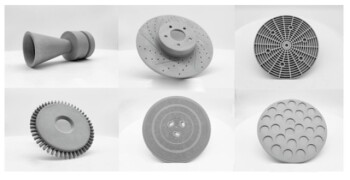

Advanced Technologies for Precision Ceramics

9 months agoExplores key technologies and preparation methods for precision ceramic components, highlighting their applications and challenges.

Learn More

Precision Ceramics in Semiconductor Applications

9 months agoExploring the use of precision ceramics in semiconductor equipment, their properties, and manufacturing processes.

Learn More

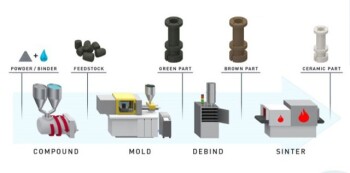

Precision Ceramic Injection Molding: Key Processes

9 months agoAn in-depth look at the stages of precision ceramic injection molding, focusing on grouting, holding pressure, cooling, and demolding.

Learn More

The 5 Hottest Advanced Ceramic Powders Currently Available!

9 months agoAn overview of the top 5 advanced ceramic powders: High Purity Aluminum Oxide, Boehmite, Aluminum Nitride, Silicon Nitride, and Spherical Alumina, highlighting their applications and market trends.

Learn More

New Rapid Sintering Technologies for Advanced Ceramics

9 months agoExplores advanced ceramic materials, their properties, and various rapid sintering techniques to enhance their performance.

Learn More

Mechanical Properties and Structural Enhancements of Ceramics

9 months agoAn in-depth analysis of the mechanical properties of ceramics, including strengths, weaknesses, and methods for improvement.

Learn More

The Evolution and Strategic Importance of Advanced Ceramics

9 months agoAn in-depth analysis of the development, classification, and strategic importance of advanced ceramics in various industrial and technological fields.

Learn More

Engineering Ceramic Materials: Applications in Aerospace, Electronic Information, New Energy, and Environmental Protection

9 months agoThis article explores the diverse applications of engineering ceramic materials across aerospace, electronic information, new energy, and environmental protection sectors.

Learn More

Advancements in Engineering Ceramic Materials

9 months agoExplores new engineering ceramics with exceptional properties and applications in harsh environments, comparing them to traditional materials.

Learn More

Structure and Properties of High-Temperature Engineering Ceramics

9 months agoExplore the applications, structural features, and performance advantages of high-temperature engineering ceramics across various industries.

Learn More

Understanding Optical Filters

9 months agoAn overview of optical filters, their types, and applications.

Learn More

Optical Filter Structures and Construction Methods

9 months agoAn overview of various optical filter structures and their construction methods, focusing on different coating techniques and assembly processes.

Learn More

Common Optical Materials and Their Properties

9 months agoAn overview of various optical materials, their properties, and applications across different spectral ranges.

Learn More

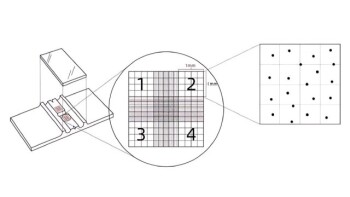

Essential Techniques in Introductory Biology: Cell Counting

9 months agoA detailed guide on the process of cell counting using a Hemocytometer, including preparation, counting methods, and cleaning.

Learn More