Articles

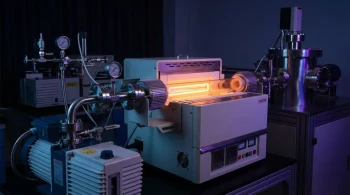

The Geometry of Heat: Why the Horizontal Tube Furnace Remains the Laboratory Workhorse

7 hours agoExplore the engineering behind horizontal tube furnaces, from heating element selection to atmospheric control, and how to achieve thermal precision.

Learn More

The Unseen Architect: How Atmosphere Control in Tube Furnaces Defines Material Destiny

19 hours agoLearn how precise atmospheric control in vacuum tube furnaces—from high vacuum to reactive gases—is crucial for defining material properties and preventing failure.

Learn More

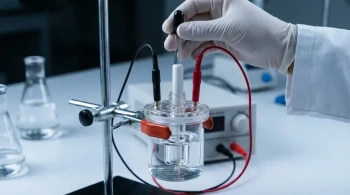

The Architecture of Control: Why the Five-Port Cell is More Than Glassware

19 hours agoMaximize experimental precision with the five-port water bath electrolytic cell. Master temperature, potential, and atmosphere for reproducible data.

Learn More

The Architecture of Certainty: Why Precision Demands a Tube Furnace

1 day agoHeat is easy; consistency is hard. Discover why the cylindrical geometry and atmospheric control of tube furnaces make them essential for precise material science.

Learn More

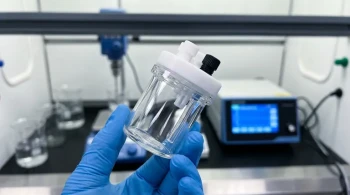

The Transparency Paradox: Mastering the Fragile Precision of All-Quartz Cells

1 day agoQuartz cells offer unmatched optical purity but demand rigorous discipline. Learn the essential protocols for inspection, thermal management, and handling.

Learn More

Beyond Glue: The Controlled Alchemy of Hot Press Lamination

1 day agoHot press lamination is not just adhesion; it's a controlled transformation using heat and pressure to forge structurally superior materials.

Learn More

The Geometry of Heat: Why Control Matters More Than Temperature

2 days agoTube furnaces are not just heaters; they are isolation chambers. Discover how controlling atmosphere and gravity transforms raw materials into innovation.

Learn More

The Geometry of Control: Why Millimeters Matter in Electrochemistry

2 days agoUnderstanding the standard specifications of quartz electrolytic cells—Φ6.2mm and Φ3.2mm openings—and how they define experimental boundaries.

Learn More

From Powder to Perfection: The Critical Choice Between Uniaxial and Isostatic Pressing

2 days agoUniaxial hot pressing shapes materials, but isostatic pressing (HIP) perfects them by eliminating hidden internal flaws. Understand the crucial difference.

Learn More

The Thermodynamics of Ambition: Redefining High Temperature in Vacuum Furnaces

3 days agoDiscover why "high temperature" is relative in vacuum furnaces. From standard annealing to 2200°C sintering, learn how to match heat to material potential.

Learn More

The Invisible Variable: Mastering the Art of Electrolytic Cell Integrity

3 days agoData reliability relies on more than just theory. Discover the systematic maintenance protocol—pre-check, monitoring, and cleaning—that guarantees precision.

Learn More

Mastering the Micro-Environment: Why the Tube Furnace Is a Scientist's Most Powerful Tool for Innovation

3 days agoExplore how tube furnaces provide the precise temperature, atmosphere, and purity control essential for breakthroughs in materials science and R&D.

Learn More

The Architecture of the Invisible: Mastering the CVD Tube Furnace

4 days agoChemical Vapor Deposition (CVD) turns gas into solid with atomic precision. Explore how this complex reactor system works and why it defines modern material science.

Learn More

The Silent Decay: Why the Experiment Doesn't End When the Power Cuts

4 days agoThe success of your next experiment depends on how you end the current one. Discover the systemic approach to electrolytic cell maintenance and safety.

Learn More

The Physics of Perfection: Why Hot Pressing is an Investment in Material Certainty

4 days agoHot press forming isn't just about shape; it's a strategic process for creating dense, stable, and flawless materials by mastering heat and pressure.

Learn More

Gravity, Geometry, and Heat: The Engineering Behind Tube Furnace Orientation

5 days agoDiscover how tube furnace orientation—horizontal, vertical, or rotary—dictates thermal thermodynamics, sample integrity, and experimental success.

Learn More

The Architecture of Control: Decoding the Five-Port Electrolytic Cell

5 days agoUnlock the specifics of the standard five-port electrolytic cell (3x Φ6.2mm, 2x Φ3.2mm) and why precise customization is the key to reproducible electrochemistry.

Learn More

Beyond Brute Force: Why the Strongest Materials Fail and How Your Lab Can Predict It

5 days agoLearn why focusing on brute force is a mistake. Discover how understanding material microstructure—not just specs—prevents failure and how to fix it.

Learn More

The Invisible Trade-off: Balancing Speed and Purity in Vacuum Quenching

6 days agoNitrogen offers speed; Argon offers purity. Discover the engineering psychology behind choosing the right quenching gas to balance cost against metallurgical integrity.

Learn More

The Invisible Architecture of Accuracy: Mastering Electrode Installation

6 days agoMaster the lifecycle of electrode installation—from inspection to alignment and maintenance—to ensure safety and reproducibility in electrochemical experiments.

Learn More

Beyond Brute Force: The Engineering Logic of Uniform Pressure

6 days agoDiscover how Cold Isostatic Pressing (CIP) uses hydrostatic force to create flawless components with uniform density, solving complex manufacturing challenges.

Learn More

The Engineering of Nothingness: Why Perfection Requires a Vacuum

1 week agoVacuum furnaces trade atmospheric chaos for controlled purity. Explore how heat treating, brazing, and sintering in a void creates superior metallurgy.

Learn More

The Engineer's Gambit: Why Molybdenum Defines the Modern Vacuum Furnace

1 week agoDiscover why molybdenum is key to vacuum furnace purity and how hot zone design dictates temperature uniformity in critical manufacturing processes.

Learn More

The Architecture of Stability: Mastering Control with Double-Layer Electrolytic Cells

1 week agoChemistry is a battle against variables. Discover how double-layer electrolytic cells (30ml-1000ml) provide the thermal and atmospheric control you need.

Learn More

The Architecture of Emptiness: How Vacuum Tube Furnaces Defy Entropy

1 week agoDiscover the precise engineering behind vacuum tube furnaces. Learn how thermal isolation and high-vacuum systems create the ultimate environment for material purity.

Learn More

The Unseen Discipline: Mastering the Alumina Furnace Tube

1 week agoLearn how proactive maintenance, not just reactive cleaning, prevents thermal shock and contamination to ensure the integrity of your lab results.

Learn More

The Geometry of Trust: Stabilizing the Electrochemical Cell

1 week agoData integrity begins with physical stability. Learn how to adjust your PTFE electrode stand to master gravity, eliminate vibration, and ensure reproducibility.

Learn More

The Geometry of Heat: Navigating the Choice Between Tube and Box Furnaces

1 week agoDiscover the systemic difference between continuous tube furnaces and static box furnaces. Learn how workflow dictates your hardware choice.

Learn More

The Architecture of Silence: Why Quartz Defines Electrochemical Precision

1 week agoIn electrochemistry, the vessel is as critical as the catalyst. Discover why quartz's unique properties make it the unseen hero of precise experimentation.

Learn More

The Physics of Permanence: Why a T-Shirt Press and a Circuit Bonder Are the Same, Yet Worlds Apart

1 week agoHot press machines use controlled heat and pressure, but the psychology of risk dictates their design—from simple transfers to mission-critical electronics.

Learn More