Articles

How to Choose Crucible Materials That Prevent Chemical Degradation in Vacuum Induction Melting

6 months agoLearn how to choose crucible materials for vacuum induction melting to prevent chemical degradation and optimize alloy purity. Essential guide for industrial applications.

Learn More

How Vacuum Induction Melting Prevents Catastrophic Material Failures in Critical Components

6 months agoDiscover how Vacuum Induction Melting (VIM) prevents material failures in aerospace, nuclear, and EV components by eliminating atomic-level contamination.

Learn More

How Vacuum Induction Melting Elevates High-Performance Alloy Production

6 months agoDiscover how Vacuum Induction Melting (VIM) enhances alloy purity, reduces defects, and optimizes costs for aerospace and energy sectors.

Learn More

How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

6 months agoDiscover how vacuum induction melting (VIM) outperforms traditional methods in advanced alloy production, offering precision, purity, and cost savings.

Learn More

How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

6 months agoDiscover how Vacuum Induction Melting (VIM) enhances alloy purity for aerospace, medical, and nuclear industries, reducing defects and costs.

Learn More

How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

6 months agoVacuum induction melting (VIM) ensures metallurgical purity, durability, and efficiency in aerospace, nuclear, and critical industries. Learn why VIM outperforms traditional methods.

Learn More

How Vacuum Induction Melting Powers Superior Material Performance in Critical Industries

6 months agoDiscover how Vacuum Induction Melting (VIM) ensures 99.99% pure alloys for aerospace and medical industries, boosting performance and compliance.

Learn More

How Freeze-Drying Cuts Transport Costs by 90% in Critical Logistics

6 months agoFreeze-drying slashes transport costs by 90% in logistics for space, military, and disaster relief by reducing weight and volume. Learn how it works.

Learn More

Freeze-Drying Decoded: The Science Behind Preserving Food, Medicine, and Research Materials

6 months agoDiscover how freeze-drying preserves food, medicine, and research materials with unmatched efficiency. Learn the science behind lyophilization and its applications.

Learn More

Why Freeze-Drying is Indispensable for Preserving Sensitive Samples

7 months agoFreeze-drying preserves sensitive samples by sublimation, maintaining molecular integrity and enabling stable, room-temperature storage. Essential for proteins, vaccines, and volatile compounds.

Learn More

How Freeze-Drying Protects Delicate Biological Structures During Water Removal

7 months agoFreeze-drying preserves biological samples by removing water without structural damage, ideal for vaccines, enzymes, and microbial cultures. Learn how it works.

Learn More

How Laboratory Freeze Dryers Outperform Alternatives in Pharma, Food, Biotech & Research

7 months agoDiscover how lab freeze dryers outperform traditional methods in pharma, food, biotech & research—preserving potency, nutrients & integrity.

Learn More

How Cascade Refrigeration Powers Ultra-Low Temperature Freezers Beyond Single-Stage Limits

7 months agoLearn how cascade refrigeration enables ultra-low temperature freezers to reach -80°C and beyond, overcoming single-stage system limitations for critical sample storage.

Learn More

Why Ultra-Low Temps are Non-Negotiable: The Science Behind Preserving Critical Biological Materials

7 months agoDiscover why ultra-low temperature freezers (-86°C) are vital for preserving cells, proteins, and vaccines. Learn the science behind ULT storage best practices.

Learn More

Upright vs. Chest ULT Freezers: How to Choose the Right Configuration for Your Lab

7 months agoCompare upright vs. chest ULT freezers for your lab: temperature stability, workflow efficiency, and cost analysis to protect sensitive samples.

Learn More

How ULT Freezers Prevent Catastrophic Loss of Microbiological Samples

7 months agoULT freezers safeguard microbiological samples with advanced temperature control, contamination prevention, and emergency backup systems to prevent catastrophic loss.

Learn More

Beyond the Spec Sheet: Matching Freeze Dryer Capabilities to Your Application's Critical Needs

7 months agoChoose the right freeze dryer for pharma, food, or biotech. Key specs like cold trap temp, vacuum, and cooling rate impact drying speed and product quality.

Learn More

How ULT Freezers Protect Scientific Discoveries in Genetics and Drug Development

7 months agoULT freezers safeguard genetic and pharmaceutical research by maintaining -80°C storage for DNA, proteins, and cell lines—preventing sample degradation and ensuring research validity.

Learn More

Preserving the Irreplaceable: How ULT Freezers Protect Critical Samples Across Industries

7 months agoULT freezers at -80°C protect biological samples, vaccines, and research materials from degradation, ensuring long-term viability across industries.

Learn More

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

7 months agoExplore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.

Learn More

Performance and application of polytetrafluoroethylene (PTFE) in high temperature environment

7 months ago

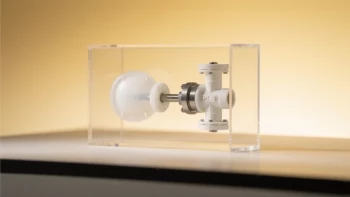

PTFE seals: the invisible guardian of industrial leakage prevention

8 months agoPTFE Seals are used to prevent liquid or gas leakage and are widely used in valves, pumps, and piping systems.

Learn More

PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

8 months agoThe unique advantages of polytetrafluoroethylene (PTFE) in high temperature and corrosion resistance analyze why it has become an indispensable material in industry, especially in applications in harsh environments.

Learn More

Innovative Application of PTFE in Mechanical Seals

8 months agoPTFE has become one of the core materials in the field of mechanical seals due to its unique chemical stability, low friction coefficient (0.04-0.15), wide temperature range (-268°C to +315°C) and excellent corrosion resistance (pH 0-14).

Learn More

The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

8 months agoFrom high-purity gas delivery pipelines to precision electrical insulation components, the multi-faceted application of PTFE in the semiconductor industry chain provides important guarantees for the purity, stability and reliability of the manufacturing process.

Learn More

How to use PTFE to improve the working efficiency of pumps and valves

8 months agoPolytetrafluoroethylene (PTFE) has become a key material for improving the efficiency of pumps and valves due to its unique physical and chemical properties.

Learn More

PTFE gasket: an all-around solution for flange sealing

8 months agoPolytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

Learn More

Development and Principles of Frozen Tissue Crushers

9 months agoExplore the history, classification, and principles of frozen tissue crushers, including grinding ball selection and how to choose the right crusher.

Learn More

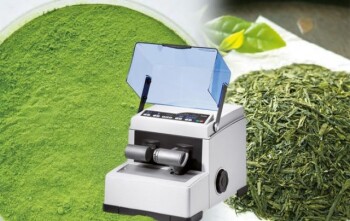

Application of Ultra-Micro Pulverization Technology in the Food Industry

9 months agoExplores the benefits and applications of ultra-micro pulverization technology in enhancing food processing and nutrient absorption.

Learn More

Cryogenic Pulverization Technology and Its Applications

9 months agoExplores the process, advantages, disadvantages, and applications of cryogenic pulverization in various fields.

Learn More