You’ve just run a critical brazing cycle in your state-of-the-art vacuum furnace. You expect a pristine, perfectly joined component to emerge. Instead, you pull out a discolored, slightly warped part. The joint is weak, brittle, and clearly a failure. Even worse, the inside of your expensive furnace is now coated with a strange, metallic film. What on earth went wrong?

The Endless Cycle of Troubleshooting: Why Common Fixes Fail

If this scenario feels familiar, you're not alone. Many engineering and production teams find themselves trapped in a frustrating loop of trial and error. They meticulously adjust the heating and cooling rates, tweak the vacuum levels, or swap out different brazing alloys, hoping to find the magic formula.

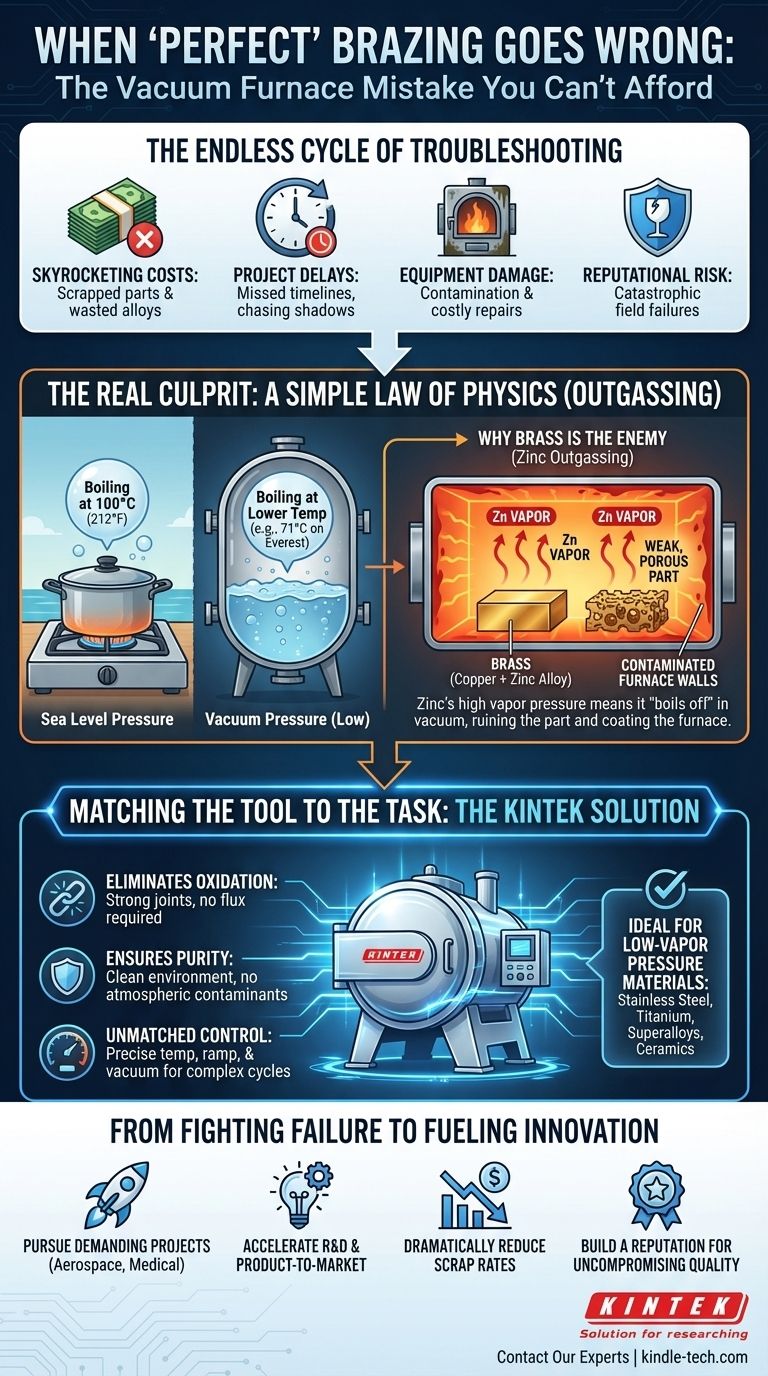

Each failed attempt isn't just a technical setback; it's a direct hit to your bottom line. These failures lead to:

- Skyrocketing Costs: High-value components are scrapped, and expensive alloys are wasted.

- Project Delays: Critical timelines are missed as your team chases a problem that seems to have no logical cause.

- Equipment Damage: The mysterious contamination inside your furnace isn't just messy; it can compromise future jobs and require costly, intensive cleaning or repair.

- Reputational Risk: If a weak joint slips through quality control, the consequences of a field failure for a medical or aerospace component can be catastrophic.

The problem is, these "common fixes" are like trying to fix a car's engine by changing the tires. They are addressing the wrong issue because they are based on a misunderstanding of the core problem.

The Real Culprit: A Simple Law of Physics You Can't Ignore

The turnabout moment comes when we stop blaming the equipment and start understanding the environment. The power of a vacuum furnace—its ability to remove oxygen and prevent oxidation—is also the source of its biggest limitation. The secret lies in a concept you learned in high school science: boiling points.

Think about boiling water. At sea level, it boils at 100°C (212°F). But if you were on top of Mount Everest, where the air pressure is much lower, water would boil at only 71°C (160°F).

A vacuum furnace creates an environment with extremely low pressure. In this environment, certain metallic elements don't need to reach their normal, atmospheric boiling point to turn into a gas. They "boil off" at the much lower temperatures used for brazing. This phenomenon is called outgassing.

Why Brass is the Enemy of Your Vacuum Furnace

This is precisely why you should never braze brass in a vacuum furnace. Brass is an alloy of copper and zinc. Zinc has a very high vapor pressure, meaning it is eager to turn into a gas. When you heat brass under vacuum, the zinc effectively boils out of the alloy.

This destructive process does two things:

- It fundamentally changes the composition of your part, leaving it weak and porous.

- The vaporized zinc travels through the furnace and condenses on the cool, interior walls, contaminating it for every subsequent job.

This isn't a quality control issue; it's a law of physics. No amount of tweaking the furnace settings can change the fact that you are attempting to use a process that is fundamentally incompatible with your material. The same holds true for any alloy containing cadmium or lead.

Matching the Tool to the Task: The Principle of Correct Application

The solution, therefore, isn't a "better" vacuum furnace; it's about using the right process for the right material.

For materials that don't contain high vapor pressure elements—like stainless steel, titanium, superalloys, and ceramics—a vacuum furnace is the undisputed champion. For these applications, you need a tool that is engineered with a deep understanding of thermal processing.

This is where a KINTEK vacuum furnace excels. It is not just a heater; it is an active environment controller designed to embody the solution:

- It Eliminates Oxidation: By creating a deep vacuum, it removes the reactive gases that prevent a perfect metallurgical bond, resulting in strong, clean joints without the need for corrosive chemical fluxes.

- It Ensures Purity: The clean, controlled environment guarantees that the joint's integrity is not compromised by atmospheric contaminants.

- It Provides Unmatched Control: Our systems offer the precise control over temperature, ramp rates, and vacuum levels needed to execute complex, multi-step thermal processes like annealing or stress-relieving in the same cycle.

A KINTEK furnace is the ideal tool when your goal is maximum joint strength and purity for critical components. It is the product of a design philosophy that respects the underlying physics of the process.

Beyond the Fix: From Fighting Failure to Fueling Innovation

When you stop fighting your tools and start leveraging the right process, your team's entire focus shifts. The daily question is no longer, "Why did this batch fail?" but rather, "What new, complex component can we create next?"

Mastering your thermal processes unlocks new potential:

- Confidently pursue more demanding projects, such as those for aerospace, medical, or high-end electronics, where joint reliability is non-negotiable.

- Accelerate R&D and product-to-market cycles because your process is predictable and repeatable.

- Dramatically reduce scrap rates and the associated material and labor costs.

- Build a reputation for uncompromising quality, transforming a manufacturing process from a liability into a competitive advantage.

Solving a brazing challenge is about more than just one successful joint; it's about building a reliable, scalable manufacturing capability that gives you a competitive edge. If you're ready to move past guesswork and implement a process that delivers consistent, high-quality results for your critical projects, our team is here to help. We can guide you in selecting the precise equipment that aligns with your materials and your goals. Let's discuss your unique application. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- The Art of the Void: When Precision Matters More Than Power