You’ve done everything by the book. The components are meticulously designed, the furnace profile is programmed to the exact degree, and you’re using a high-grade filler alloy. The cycle completes, you open the furnace, and your heart sinks. Some joints are perfect, strong, and clean. Others are weak, porous, or didn't form at all. It’s another batch with an unacceptable failure rate, and you’re back to square one, with deadlines looming and costs mounting.

If this scenario feels painfully familiar, you are not alone.

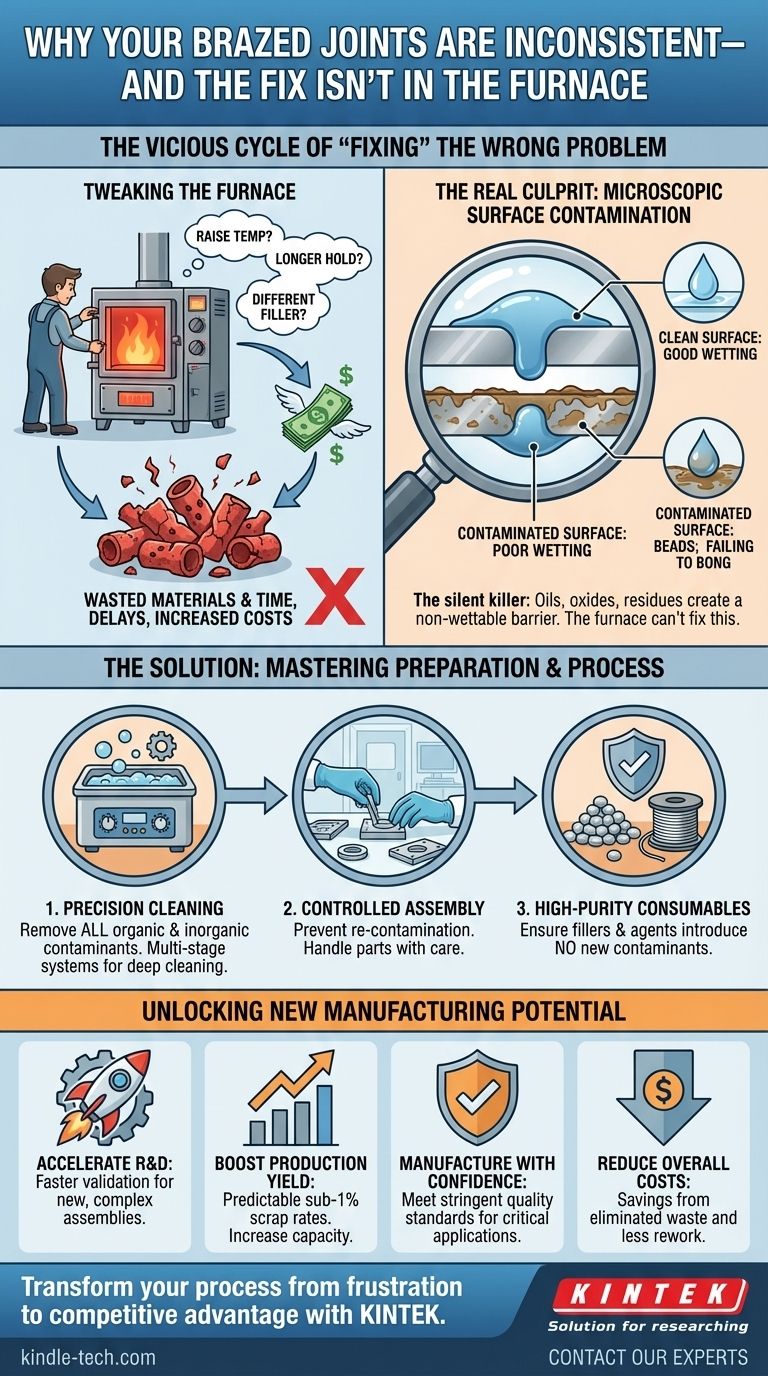

The Vicious Cycle of "Fixing" the Wrong Problem

When faced with inconsistent brazing results, most engineering and production teams instinctively turn to the most visible part of the process: the furnace. The response is a frantic cycle of adjustments:

- "Let's raise the peak temperature by 10 degrees."

- "Maybe we need a longer hold time."

- "Try a different filler metal paste."

- "Let's adjust the joint clearance by a few thousandths of an inch."

Each tweak requires another expensive, time-consuming furnace run, yet the results remain stubbornly unpredictable. This isn't just a technical frustration; it's a significant business drain. Every failed batch translates directly into wasted high-value materials, lost production hours, and delayed project timelines. For critical components in aerospace or medical devices, this inconsistency introduces a level of risk that is simply unacceptable, jeopardizing contracts and a company's reputation.

The struggle is real because these efforts, while logical, are focused on the symptoms, not the disease. The true source of the problem is often established long before your parts even feel the heat.

The Real Culprit: A Microscopic Battle on the Metal's Surface

The success or failure of a brazed joint is decided by a fundamental principle of physics: wetting.

Think of it like water on glass. On a perfectly clean pane of glass, a drop of water spreads out into a thin, even film. This is good wetting. On a waxy or greasy surface, the same drop of water beads up and refuses to spread. This is poor wetting.

Molten brazing filler behaves in exactly the same way. It needs a perfectly clean, high-energy metal surface to flow into the joint through capillary action and form a strong, continuous bond.

The silent killer of your joint is a microscopic layer of contamination—oils from handling, residual drawing compounds, or invisible oxide films that form instantly on most metals exposed to air. When you place a seemingly "clean" part into the furnace, the intense heat dramatically accelerates the reaction between this contamination and the metal surface, creating a stubborn, non-wettable barrier.

This is why your other fixes fail. It doesn't matter how perfect your temperature is or how advanced your filler alloy is. If the molten filler is physically repelled by the contaminated surface, it cannot and will not form a proper joint. You're trying to glue a dusty surface—the failure is pre-ordained.

From Guesswork to Guarantee: The Right Tools for a Flawless Process

To conquer inconsistency, you must shift your focus from tweaking the furnace to mastering the preparation. You don't need to guess; you need a systematic, repeatable process that guarantees a truly clean, active surface every single time.

This is where a process-oriented approach, supported by the right equipment and consumables, transforms brazing from a black art into a reliable science. The goal is to create a component surface so pristine that good wetting is not just possible, but inevitable.

This is achieved by implementing a robust pre-brazing protocol:

- Precision Cleaning: To remove all organic and inorganic contaminants. This goes beyond a simple wipe-down, often requiring multi-stage ultrasonic cleaning systems that can reach into the microscopic peaks and valleys of a metal's surface.

- Controlled Assembly: To prevent re-contamination between cleaning and furnace loading. Handling parts—even with gloves—can transfer enough residue to compromise a joint.

- High-Purity Consumables: To ensure that the filler metals and any cleaning agents you use don't introduce new, unexpected contaminants into the equation.

KINTEK's equipment and consumables are designed based on this deep understanding of the process. Our solutions are not just products; they are enablers of a reliable system. They directly target and eliminate the root cause of failure—surface contamination—allowing your furnace to do what it does best.

Beyond Reliable Joints: Unlocking New Manufacturing Potential

Once you eliminate the guesswork and solve the chronic problem of inconsistency, the entire dynamic of your operation changes. Reliable brazing doesn't just mean fewer failed parts; it unlocks a new level of manufacturing capability.

- Accelerate R&D: You can now confidently develop processes for new, complex assemblies or challenging dissimilar materials, knowing your baseline is stable. Validation time can shrink from months to weeks.

- Boost Production Yield: Imagine reducing your scrap rate from a painful 15% to a predictable sub-1%. You've effectively increased your production capacity without adding a single new furnace.

- Manufacture with Confidence: For industries where failure is not an option, you can build parts with the assurance that every single joint meets stringent quality and performance standards. This opens the door to more demanding and lucrative contracts.

- Reduce Overall Costs: The savings from eliminated waste, reduced labor for rework, and faster production cycles go straight to your bottom line.

By shifting focus to the fundamentals and implementing a robust preparation process, you're not just fixing a joint; you're transforming your entire manufacturing potential.

Let's move your process from a source of frustration to a competitive advantage. Our team understands the microscopic details that determine macroscopic success. We can help you analyze your current workflow and build a reliable, high-yield brazing process tailored to your specific components and business goals. To start the conversation about your project, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- Mastering Vacuum Furnace Brazing: Techniques, Applications, and Advantages

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Materials Science with the Lab Vacuum Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity