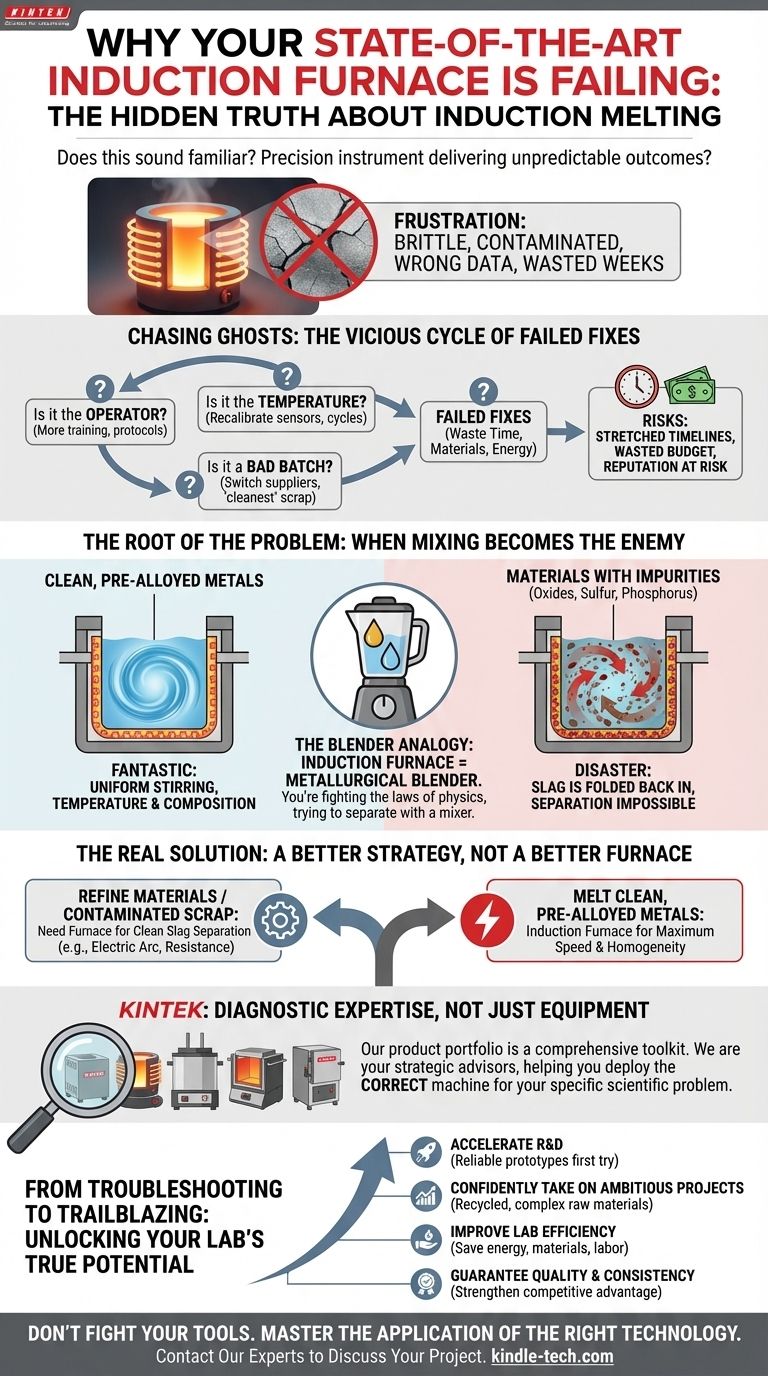

Does this sound familiar? You've invested in a state-of-the-art induction furnace, seduced by its promise of speed, efficiency, and precise temperature control. You expect clean, consistent results. Yet, you find yourself staring at a finished product that’s brittle, contaminated, or just plain wrong. The data is all over the place, and weeks of work have yielded nothing but frustration. You bought a precision instrument, but you're getting unpredictable outcomes.

You are not alone in this struggle. This is one of the most common and perplexing problems in many modern labs and foundries.

Chasing Ghosts: The Vicious Cycle of Failed Fixes

When faced with inconsistent quality, the natural response is to start troubleshooting the obvious. Teams often go down a checklist of common culprits:

- "Is it the operator?" You invest in more training, stricter protocols, and double-checking every step. Yet, the problem persists.

- "Is it the temperature?" You recalibrate sensors and tweak heating cycles, chasing that perfect temperature profile. Still, no consistent improvement.

- "Is it a bad batch of material?" You switch suppliers or use only the "cleanest" available scrap, only to find the underlying issue remains, lurking beneath the surface.

Each failed attempt doesn't just waste time and materials; it has serious business consequences. Project timelines stretch from weeks into months. Budgets are consumed by wasted energy and scrapped material. Most importantly, your reputation for delivering reliable, high-quality products is put at risk. You're caught in a cycle of treating symptoms, while the real disease goes undiagnosed.

The Root of the Problem: When Mixing Becomes the Enemy

The frustrating truth is that the very feature that makes induction melting so powerful is also its greatest weakness. The solution lies not in your operational procedures, but in the fundamental physics of the furnace itself.

An induction furnace works by creating a powerful electromagnetic field. This field heats the conductive metal directly and, crucially, creates a vigorous, continuous stirring action.

- For clean, pre-alloyed metals, this is fantastic. The stirring ensures the melt is perfectly uniform in temperature and composition.

- But for any material with impurities (like oxides, sulfur, or phosphorus), this stirring is a disaster.

The Blender Analogy

Imagine you want to separate oil and water. Would you use a high-speed blender? Of course not. The blender's very purpose is to mix everything together, making separation impossible.

An induction furnace acts like a metallurgical blender.

Impurities are meant to separate from the metal and form a layer of "slag" on top, which can then be removed. However, the furnace's intense stirring action constantly folds this slag back into the molten metal. Worse yet, the electromagnetic field only heats the metal, leaving the slag cooler and less fluid, making it even harder to separate.

This is why your previous fixes failed. You were trying to get a blender to do the job of a centrifuge. You weren't fighting a bad operator or faulty equipment; you were fighting the laws of physics.

The Real Solution: It's Not a Better Furnace, It's a Better Strategy

To truly solve this problem, you need to stop asking your induction furnace to do a job it was never designed for. The goal is not to find a "better" induction furnace, but to match the right melting technology to your specific metallurgical task.

- If you need to refine materials or melt contaminated scrap, you need a furnace that allows slag to separate cleanly, often one that heats the slag农业 as aggressively as the metal.

- If you need to melt clean, pre-alloyed metals with maximum speed and homogeneity, then an induction furnace is a superb choice.

This is where having an expert partner becomes critical. At KINTEK, we don't just sell equipment; we provide diagnostic expertise. Our product portfolio isn't limited to a single technology. It's a comprehensive toolkit designed to solve a wide range of laboratory challenges.

We understand that an induction furnace is the perfect tool for remelting, while an electric arc or a specialized resistance furnace might be required for refining. Our core value is not in selling you the most advanced machine, but in helping you deploy the correct one. We are your strategic advisors, ensuring the equipment you choose is a direct solution to the scientific problem you are trying to solve.

From Troubleshooting to Trailblazing: Unlocking Your Lab's True Potential

When you stop fighting your tools and start using the right one for every job, a fundamental shift occurs. The energy once spent on endless troubleshooting is now liberated for innovation.

Instead of re-running failed experiments, your team can:

- Accelerate R&D cycles, getting reliable material prototypes董事 on the first try.

- Confidently take on more ambitious projects, including those involving recycled or complex raw materials.

- Improve overall lab efficiency, saving significant costs on energy, materials, and labor.

- Guarantee the quality and consistency of your output, strengthening your reputation and competitive advantage.

Choosing the right tool transforms your lab from a place of constant problem-solving into an engine of discovery.

Your melting process shouldn't be a source of uncertainty. True success in the lab comes not from owning the most talked-about technology, but from mastering the application of the right technology. Our team doesn't just sell equipment; we partner with you to diagnose your unique material challenges and align you with the most effective and efficient solution. Let's move beyond troubleshooting and start optimizing your entire workflow. Contact Our Experts to discuss your project and discover the right solution for your goals.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

Related Articles

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- How Vacuum Induction Melting Powers Superior Material Performance in Critical Industries

- Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys

- How Vacuum Induction Melting Prevents Catastrophic Material Failures in Critical Components

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries