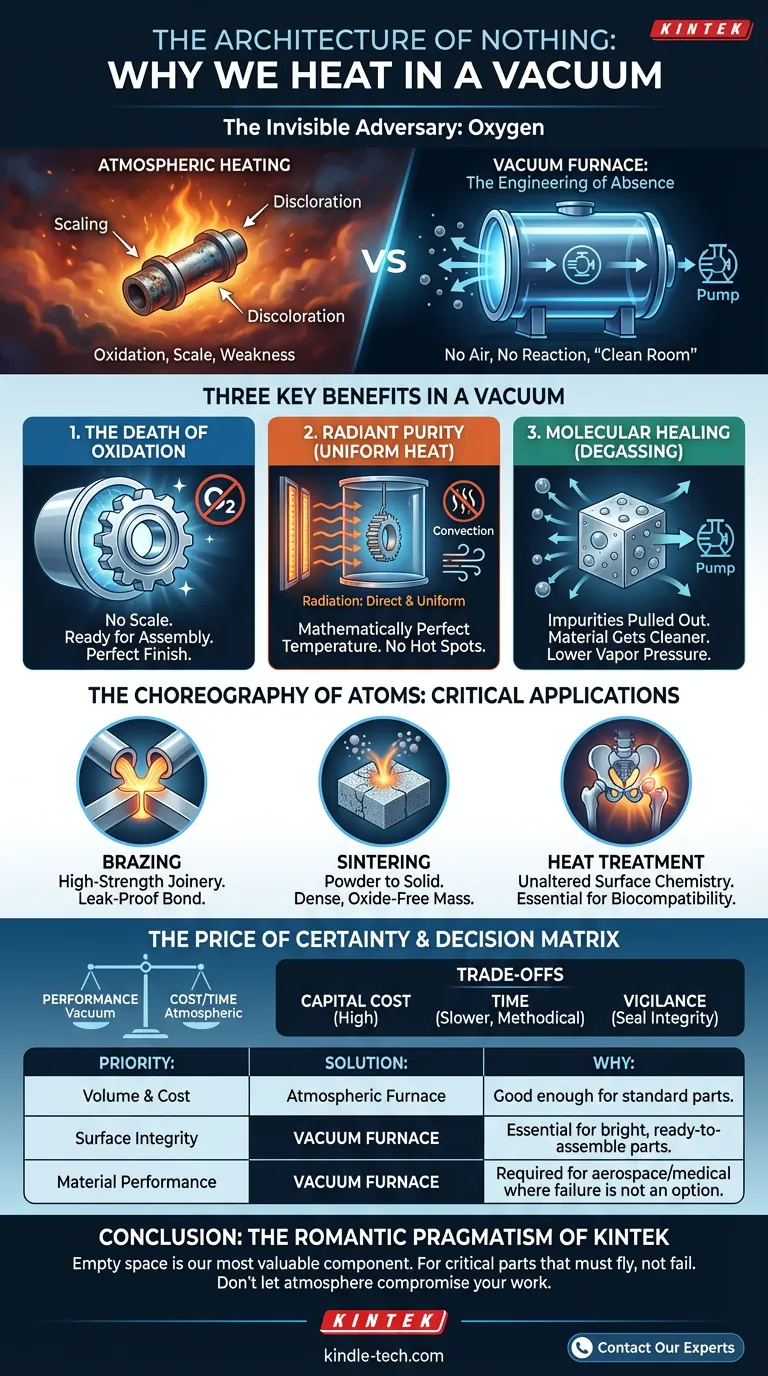

The Invisible Adversary

In the high-stakes world of material science, oxygen is a thief.

We tend to think of fire and heat as constructive forces—tools we use to forge, harden, and shape the world. But at the molecular level, heat acts as an accelerant for chaos. When you heat metal in the presence of air, it doesn't just get hot. It reacts.

It scales. It discolors. It weakens.

This is the fundamental paradox of metallurgy: to make a material stronger, you must heat it; but by heating it, you risk destroying the very surface integrity you are trying to preserve.

The vacuum furnace is the engineering answer to this paradox. It is a specialized oven, yes. But its defining feature isn't the heat it generates. It is the emptiness it creates.

The Engineering of Absence

A conventional furnace fights a losing battle against the atmosphere. A vacuum furnace removes the battlefield entirely.

By pumping air and gases out of the sealed chamber before the heating cycle begins, the furnace creates a "clean room" for atoms. This absence of air changes the rules of physics inside the chamber in three distinct ways.

1. The Death of Oxidation

Oxidation is the enemy of performance. In an open-air furnace, metals react aggressively with oxygen, forming a crusty layer of scale.

In a vacuum, oxidation is impossible. The result is a part that emerges bright, shiny, and clinically clean. There is no need for acid baths or sandblasting after the fact. The part is perfect the moment it cools.

2. Radiant Purity

In a standard oven, heat rides on air currents (convection). This is messy. It creates hot spots and cold corners.

In a vacuum, there is no air to carry the heat. Energy travels solely through radiation—direct lines of infrared energy transferring from the heating elements to the workpiece. This allows for temperature uniformity that is almost mathematically perfect, essential for sensitive aerospace alloys.

3. Molecular Healing

Some processes, like degassing, actually pull impurities out of the metal. The vacuum lowers the vapor pressure, enticing trapped gases within the metal to surface and be pumped away. The material doesn't just stay clean; it gets cleaner.

The Choreography of Atoms

When you remove the noise of the atmosphere, you can perform delicate operations that would otherwise be impossible.

The vacuum furnace is the stage for three critical industrial ballets:

- Brazing: This is high-strength joinery. In a vacuum, the filler metal flows like water into the capillaries between parts. Without oxides to block the path, the bond becomes leak-proof and often stronger than the base metal itself.

- Sintering: Turning powder into solid metal. To fuse properly, metal powder particles must touch directly. A vacuum strips away the oxide layers on these microscopic grains, allowing them to merge into a dense, solid mass.

- Heat Treatment: Whether it is hardening or annealing, doing it in a vacuum ensures the chemical composition of the surface remains unaltered. This is non-negotiable for medical implants where surface chemistry interacts with human biology.

The Price of Certainty

If vacuum furnaces are so superior, why don't we use them for everything?

Because perfection is expensive.

In engineering, as in life, there are always trade-offs. The "tax" you pay for the performance of a vacuum furnace comes in three forms:

- Capital Cost: These are complex systems involving heavy vessels, sophisticated pumps, and leak-proof seals. They cost significantly more than atmospheric ovens.

- Time: You cannot just open the door and throw a part in. You must seal the chamber, pump it down to a deep vacuum, process the part, and then backfill with inert gas to cool it. It is a slow, methodical rhythm.

- Vigilance: A vacuum furnace is only as good as its seal. A single leak compromises the entire batch. Maintenance requires a disciplined mindset.

The Decision Matrix

When should you pay this tax?

| If your priority is... | The Solution | Why? |

|---|---|---|

| Volume & Cost | Atmospheric Furnace | Good enough for standard parts where minor oxidation is acceptable. |

| Surface Integrity | Vacuum Furnace | Essential when parts must emerge bright and ready for assembly. |

| Material Performance | Vacuum Furnace | Required for aerospace/medical parts where failure is not an option. |

Conclusion: The Romantic Pragmatism of KINTEK

There is a certain romance to the vacuum furnace—the idea that to create something of lasting strength, you must first create a void.

But for the lab manager or production engineer, it is purely pragmatic. It is the difference between a part that fails and a part that flies.

At KINTEK, we understand that the empty space inside the furnace is the most valuable component we sell. Our equipment is designed for those who cannot afford the chaos of oxidation. Whether you are sintering advanced ceramics or brazing critical sensors, our systems provide the control you need.

Don't let the atmosphere compromise your work.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Related Articles

- The Art of the Void: When Precision Matters More Than Power

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Mastering Vacuum Furnace Brazing: Techniques, Applications, and Advantages

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Materials Science with the Lab Vacuum Furnace