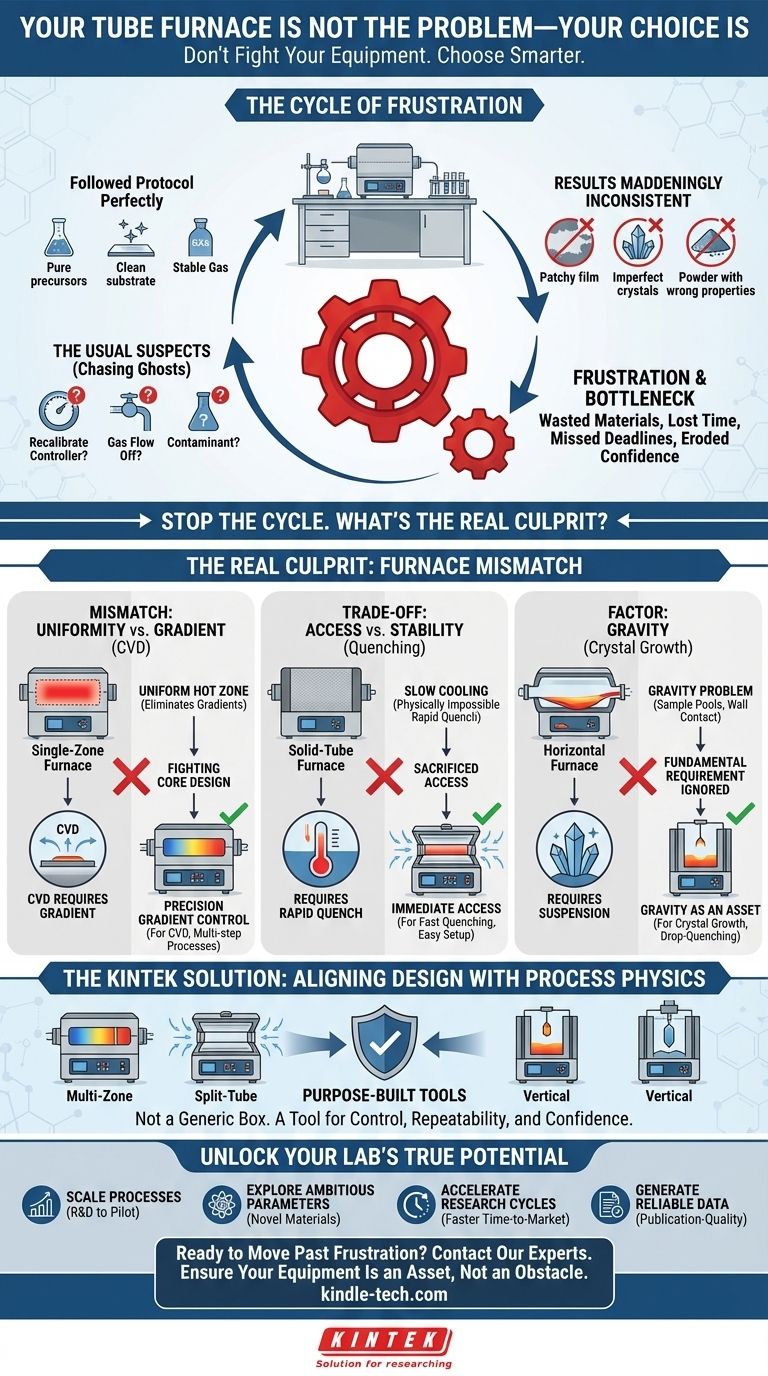

You’ve followed the protocol to the letter. The precursors are pure, the substrate is perfectly clean, and the gas flow is stable. Yet, the results are maddeningly inconsistent. The film you deposited is patchy and uneven. The crystals you tried to grow are riddled with imperfections. The powder you annealed simply doesn't have the right properties. It worked once, maybe twice, but now you can't replicate it.

Does this sound familiar? You're not alone.

The Usual Suspects: Chasing Ghosts in Your Parameters

When a thermal process fails, we instinctively blame the variables. "Maybe the temperature controller needs recalibrating," you think. "Was the gas flow rate off by a fraction?" "Did a contaminant sneak into the tube?"

So begins the frustrating cycle of troubleshooting. You spend days, even weeks, re-running experiments, tweaking temperatures by a few degrees, meticulously cleaning every component, and questioning every step of your procedure.

This isn't just a scientific puzzle; it's a business bottleneck. Each failed run consumes expensive materials, wastes valuable instrument time, and pushes project deadlines further out. The uncertainty erodes confidence, slowing down research and development and delaying the launch of new products. You're stuck troubleshooting the process instead of advancing it.

But what if the problem isn't any of these "usual suspects"? What if the issue is far more fundamental?

The Real Culprit: It's Not Your Recipe, It's Your Oven

The turning point comes when you stop asking "What's wrong with my parameters?" and start asking, "Is this the right tool for the job?"

A "tube furnace" is not a single tool. It’s a system defined by three core design axes. A mismatch between these design features and the physical requirements of your process is the true root cause of inconsistent results. Your furnace isn't broken; it may simply be the wrong kind of furnace, one whose fundamental design is actively working against your goal.

Let's break down these critical design choices.

The Mismatch: Uniformity vs. Gradient

Many researchers use a standard single-zone furnace—designed to create one large, stable, and uniform hot zone—for a process like Chemical Vapor Deposition (CVD).

- The Problem: CVD often requires a temperature gradient. You need a cooler zone to vaporize a precursor and a hotter zone for it to decompose and deposit onto a substrate.

- The Mismatch: A single-zone furnace is engineered to eliminate gradients. By using it for CVD, you are fighting its core design. No amount of parameter tweaking can create the stable, multi-zone profile you truly need. You are asking a hammer to do a screwdriver's job.

The Trade-Off: Access vs. Stability

Imagine your process requires rapidly quenching a sample from 1000°C to room temperature to lock in a specific crystalline phase. You're using a solid-tube furnace.

- The Problem: Rapid cooling is physically impossible. You must wait for the entire insulated furnace body to cool, or slowly pull the sample out, which ruins the quench.

- The Mismatch: A split-tube furnace, which opens on a hinge, is designed for this. It allows you to expose the process tube to ambient air for an almost instantaneous temperature drop. By choosing a solid-tube model for its perceived temperature stability, you've sacrificed the critical access your process demands.

The Factor: Gravity

Some processes, like growing a large single crystal or processing a molten material, require that the sample not touch the sides of the process tube. You set up your experiment in a standard horizontal furnace.

- The Problem: Gravity pulls your molten sample or growing crystal into a puddle at the bottom of the tube.

- The Mismatch: A vertical furnace uses gravity as an asset, allowing a sample to be suspended or a crystal to be "pulled" from a melt without wall contact. The choice of orientation is not a matter of convenience; it is a fundamental process requirement.

The Solution: Aligning Furnace Design with Process Physics

Once you understand that the furnace's design is the foundation of your process, the path to consistent results becomes clear. You don't need to work harder; you need to choose smarter. You need a furnace whose core design principles are perfectly aligned with the physics of your application.

This is precisely why at KINTEK, we don't just sell "tube furnaces." We provide a comprehensive range of configurations designed from the ground up to solve specific process challenges.

-

Need a precise temperature gradient for CVD? Our multi-zone tube furnaces give you independent control over each heating zone, allowing you to build and maintain the exact thermal profile your process requires, run after run.

-

Need to perform rapid cooling or use complex, sealed reactors? Our split-tube furnaces provide the immediate access necessary for fast quenching and easy setup, eliminating the physical barriers to your experiment's success.

-

Need to prevent sample contact or use gravity to your advantage? Our vertical furnaces are built to enable processes like crystal growth and drop-quenching that are simply impossible in a horizontal orientation.

Our equipment is not a generic box that heats things up. It is the embodiment of a deep understanding of thermal processes—a purpose-built tool designed to give you control, repeatability, and confidence.

Beyond Troubleshooting: Unlocking Your Lab's True Potential

When you stop fighting your equipment and start using a tool that's right for the job, everything changes. The weeks once lost to troubleshooting are now spent on innovation. Instead of questioning your results, you can build upon them with confidence.

With a correctly specified furnace, you can finally:

- Scale your process from R&D to pilot production with predictable outcomes.

- Explore more ambitious parameters and novel materials, knowing your equipment can handle it.

- Accelerate your research cycles and bring new technologies to life faster.

- Generate reliable, publication-quality data every single time.

This isn't just about fixing a failed experiment. It's about fundamentally elevating your lab's capability. If you're ready to move past the cycle of frustration and unlock the full potential of your thermal processes, our team is here to help you make the right choice. Let's discuss the specific demands of your project and ensure your equipment is an asset, not an obstacle. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Why Your Furnace Components Keep Failing—And the Material Science Fix

- Installation of Tube Furnace Fitting Tee

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- Entropy and the Alumina Tube: The Art of Precision Maintenance

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters