The Psychology of Precision

At its heart, science is an exercise in reducing uncertainty. We build instruments not just to see what happens, but to control exactly what happens.

A tube furnace is the embodiment of this philosophy. It's not merely an oven; it's a meticulously engineered environment designed to conquer two fundamental variables: temperature and atmosphere.

Its structure is not an accident. It is a series of deliberate choices, each one a testament to the pursuit of repeatable, high-fidelity results. Understanding this anatomy is understanding the physics of control.

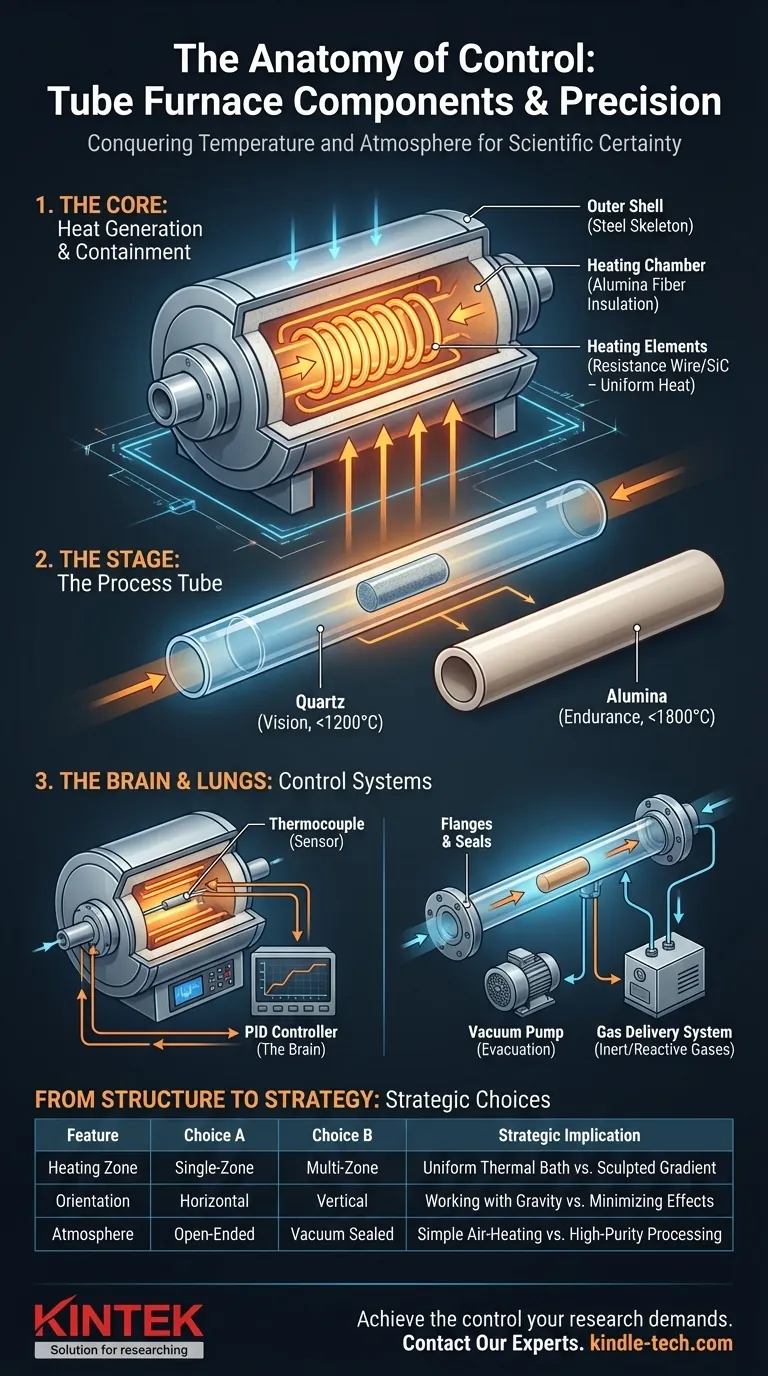

The Core: Heat Generation and Containment

Every furnace begins with a core responsible for generating and directing thermal energy.

-

The Outer Shell: This is the furnace's skeleton, typically made of heavy-duty steel. Its function is straightforward but critical: to provide structural integrity and protect the delicate internals.

-

The Heating Chamber: Inside the shell lies the heart of the furnace. This chamber, often a matrix of high-purity alumina ceramic fibers, is a masterclass in thermal insulation. Its purpose is to ensure that nearly every watt of energy is directed inward.

-

The Heating Elements: Embedded within this chamber are the elements—coils or rods that convert electricity into intense heat. The choice of material (e.g., resistance wire, silicon carbide) is a direct function of the target temperature. Their placement is engineered for one thing: thermal uniformity.

The Stage: The Process Tube

If the heating chamber is the engine, the process tube is the stage where the experiment unfolds.

This tube, passing through the center of the furnace, is the vessel that holds the sample. It creates a pristine micro-environment, isolating the material from the heating elements and the outside world.

The choice of tube material is a critical trade-off between vision and endurance.

- Quartz: Transparent and chemically inert, quartz is ideal for lower-temperature processes (up to ~1200°C) where visual observation is beneficial.

- Alumina: Opaque but incredibly durable, high-purity alumina is the standard for extreme temperatures (up to ~1800°C), offering superior stability for high-temperature annealing or sintering.

The Brain and Lungs: The Control Systems

Raw heat is useless without control. This is where the furnace's intelligence and respiratory systems come into play.

-

The Control System (The Brain): A thermocouple acts as the furnace's nerve ending, constantly sensing the temperature. It feeds this data to a PID (Proportional-Integral-Derivative) controller—the brain—which modulates power to the heating elements. This closed-loop feedback allows for precise temperature ramps, soaks, and cooling profiles, turning a brute-force heater into a precision instrument.

-

The Atmosphere System (The Lungs): For many modern materials, air is a contaminant. The atmosphere system, composed of flanges, valves, and fittings, allows you to control what the sample "breathes." A vacuum pump can evacuate the tube to remove air, while a gas delivery system can introduce a specific inert (like Argon) or reactive gas.

From Structure to Strategy: Making the Right Choices

The configuration of these components is not just a technical specification; it's a research strategy.

| Feature | Choice A | Choice B | Strategic Implication |

|---|---|---|---|

| Heating Zone | Single-Zone | Multi-Zone | Creating a uniform thermal bath vs. a sculpted gradient. |

| Orientation | Horizontal | Vertical | Working with gravity or seeking to minimize its effects. |

| Atmosphere | Open-Ended | Vacuum Sealed | Simple air-atmosphere heating vs. high-purity processing. |

A multi-zone furnace isn't just "better"; it's a tool for creating a specific thermal landscape along the length of a sample. A vertical furnace isn't an arbitrary design; it's a strategic choice for processes like crystal growth or powder synthesis where gravity is a useful force.

Your goal dictates the geometry.

Understanding these principles is the first step. Translating them into a reliable, high-performance system configured for your specific application—from annealing novel alloys to growing crystals via CVD—is the next. This requires a partner who understands the deep connection between structure and outcome.

At KINTEK, we specialize in providing laboratory equipment that is precisely tailored to your research needs. Whether you require the high-temperature resilience of an alumina tube, the fine control of a multi-zone system, or a robust vacuum setup for atmospheric purity, we help configure the ideal instrument.

Achieve the control your research demands. Contact Our Experts

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

Related Articles

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- The Silent Partner in Pyrolysis: Engineering the Perfect Thermal Boundary

- Installation of Tube Furnace Fitting Tee

- Your Tube Furnace Is Not the Problem—Your Choice of It Is