Imagine this: hours into a critical high-temperature experiment, you hear a faint crack. Your heart sinks. You glance at the furnace viewport and see the tell-tale fracture running down your expensive ceramic tube. The experiment is ruined, the sample is potentially contaminated, and weeks of work have just been lost.

If this scenario feels painfully familiar, you are not alone.

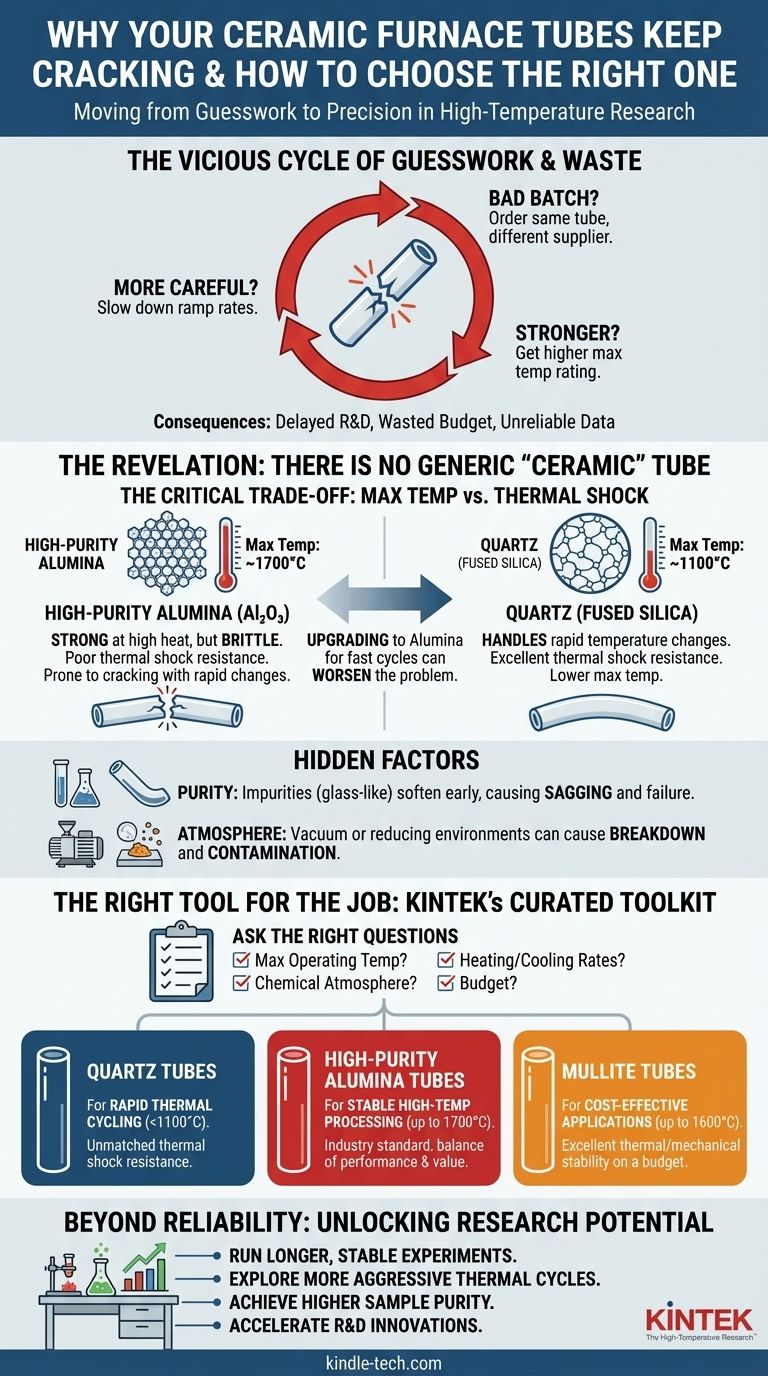

The Vicious Cycle of Guesswork and Waste

For labs working with high-temperature furnaces, unexpected tube failure is a persistent and costly headache. When a tube cracks or sags, the typical response is a frustrating process of trial and error:

- "Maybe it was a bad batch?" You order the same tube again from a different supplier, hoping for better luck.

- "I'll get a 'stronger' one." You find a tube with a higher maximum temperature rating, assuming that will solve the problem.

- "Let's just be more careful." You slow down the heating and cooling ramp rates, eating into valuable lab time and hoping it doesn't crack this time.

These repeated failures aren't just an inconvenience; they have severe business consequences. They lead to delayed R&D timelines, wasted budgets on replacement consumables and ruined samples, and worst of all, unreliable data that undermines the integrity of your entire project.

The problem is, these "solutions" almost never work long-term. Why? Because they are all based on a fundamental misunderstanding of the problem.

The Revelation: You're Asking the Wrong Question

The reason these attempts fail is that they address the symptom—a broken tube—while ignoring the root cause. Here is the simple truth:

There is no such thing as a generic "ceramic" tube.

Asking for the maximum temperature of a "ceramic tube" is like asking for the top speed of a "vehicle" without specifying if it's a bicycle or a jet aircraft. The term is too broad to be useful. The real cause of failure is almost always a mismatch between the specific material of the tube and the specific demands of your application.

The Critical Trade-Off: Max Temp vs. Thermal Shock

This is the most common point of failure. Different ceramics behave in dramatically different ways under thermal stress.

-

High-Temperature Strength (e.g., Alumina): A material engineered for extreme heat, like high-purity Alumina (Al₂O₃), has a very rigid, stable crystalline structure. This makes it incredibly strong at 1700°C, but it also makes it brittle and highly susceptible to cracking if heated or cooled too quickly. This is called poor thermal shock resistance.

-

Thermal Shock Resistance (e.g., Quartz): In contrast, a material like Quartz (Fused Silica) has a more flexible, amorphous glass structure. While its maximum temperature is lower (around 1100°C), it can handle extremely rapid temperature changes without fracturing.

This means that "upgrading" from a Quartz tube to a higher-temperature Alumina tube for an application with fast thermal cycles will actually make the problem worse. The Alumina tube, despite its higher temperature rating, is far more likely to crack under those conditions.

The Hidden Factor: Purity and Atmosphere

For materials like Alumina, purity is paramount. A 99.8% pure tube can operate reliably at 1700°C. A lower-purity version contains glass-like impurities that can soften at much lower temperatures, causing the tube to sag, deform, and fail.

Furthermore, in certain atmospheres (like a vacuum or reducing environment), some ceramics like quartz can begin to break down at high temperatures and contaminate your sample.

The Right Tool for the Job: Moving from Guesswork to Precision

To break the cycle of failure, you must stop looking for a "better tube" and start selecting the correct material. The solution requires a clear understanding of your process:

- What is your maximum operating temperature?

- How fast are your heating and cooling rates?

- What is the chemical atmosphere inside the furnace?

- What is your budget?

This is where KINTEK transforms from a supplier into a partner. Our range of high-performance ceramic tubes—from thermal-shock-resistant Quartz to high-purity Alumina and economical Mullite—isn't just a catalog of products. It is a curated toolkit, designed to provide the right solution for the specific scientific challenge you face.

- For rapid thermal cycling below 1100°C, our Quartz tubes provide the unmatched thermal shock resistance you need for reliable, repeatable results.

- For stable, high-temperature processing up to 1700°C, our high-purity Alumina tubes are the industry standard, offering a perfect balance of performance and value.

- For cost-effective furnace applications up to 1600°C, our Mullite tubes deliver excellent thermal and mechanical stability without breaking your budget.

Instead of selling you a box, we help you diagnose the underlying material science challenge and provide the precise tool to solve it.

Beyond Reliability: Unlocking New Research Potential

Once you solve the "cracked tube problem" for good, something remarkable happens. Your focus shifts from troubleshooting equipment to pioneering new discoveries. The lab's efficiency skyrockets.

You can now confidently:

- Run longer, more stable experiments without fear of interruption.

- Explore more aggressive thermal cycles to test material limits.

- Achieve higher sample purity, knowing your tube won't be a source of contamination.

- Accelerate your R&D and bring new innovations to market faster.

Ultimately, it means more reliable data, a greater return on your laboratory's investment, and a faster path to your next breakthrough.

Your research is too important to be derailed by an avoidable equipment failure. Solving the ceramic tube puzzle isn't just about preventing cracks; it's about ensuring data integrity, protecting your budget, and accelerating your project timelines. If you're ready to move past the cycle of trial-and-error and implement a solution designed for your specific needs, our team is here to help. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Entropy and the Alumina Tube: The Art of Precision Maintenance

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- Installation of Tube Furnace Fitting Tee