The Cycle Was Perfect. So Why Did the Part Fail?

You've been here before. You load a critical component into the vacuum furnace, meticulously program the heating and cooling cycle, and hit 'start'. The controller shows everything is running perfectly—temperature ramps are precise, the vacuum level is stable. Hours later, you open the door, expecting a perfectly treated part.

Instead, you find a failure.

Perhaps the part is discolored, showing signs of oxidation. Maybe it's brittle when it should be tough, or warped out of tolerance. You followed the recipe exactly. So, what went wrong? This frustrating experience, common in labs and production facilities everywhere, points to a deep misunderstanding of what a vacuum furnace truly is.

The Vicious Cycle of Tweaking, Rerunning, and Hoping

When a cycle fails, the familiar troubleshooting drill begins. We question the recipe: "Maybe we should add 10 degrees to the soak temperature?" Or we doubt the process: "Let's extend the hold time by 30 minutes." We might even blame the raw material batch.

So we tweak a parameter, cross our fingers, and run the entire costly, time-consuming cycle all over again.

This approach is more than just frustrating; it's a significant drain on resources.

- Project Delays: Each failed run pushes back R&D timelines and production schedules.

- Cost Overruns: You waste expensive materials (like specialized alloys), consume vast amounts of energy and inert gas, and burn valuable technician hours.

- Unreliable Quality: Without a clear cause, you can't guarantee product consistency. This uncertainty undermines confidence in your process and, ultimately, your final product.

But what if the temperature, the time, and the material weren't the problem at all? What if we've been looking in the wrong place entirely?

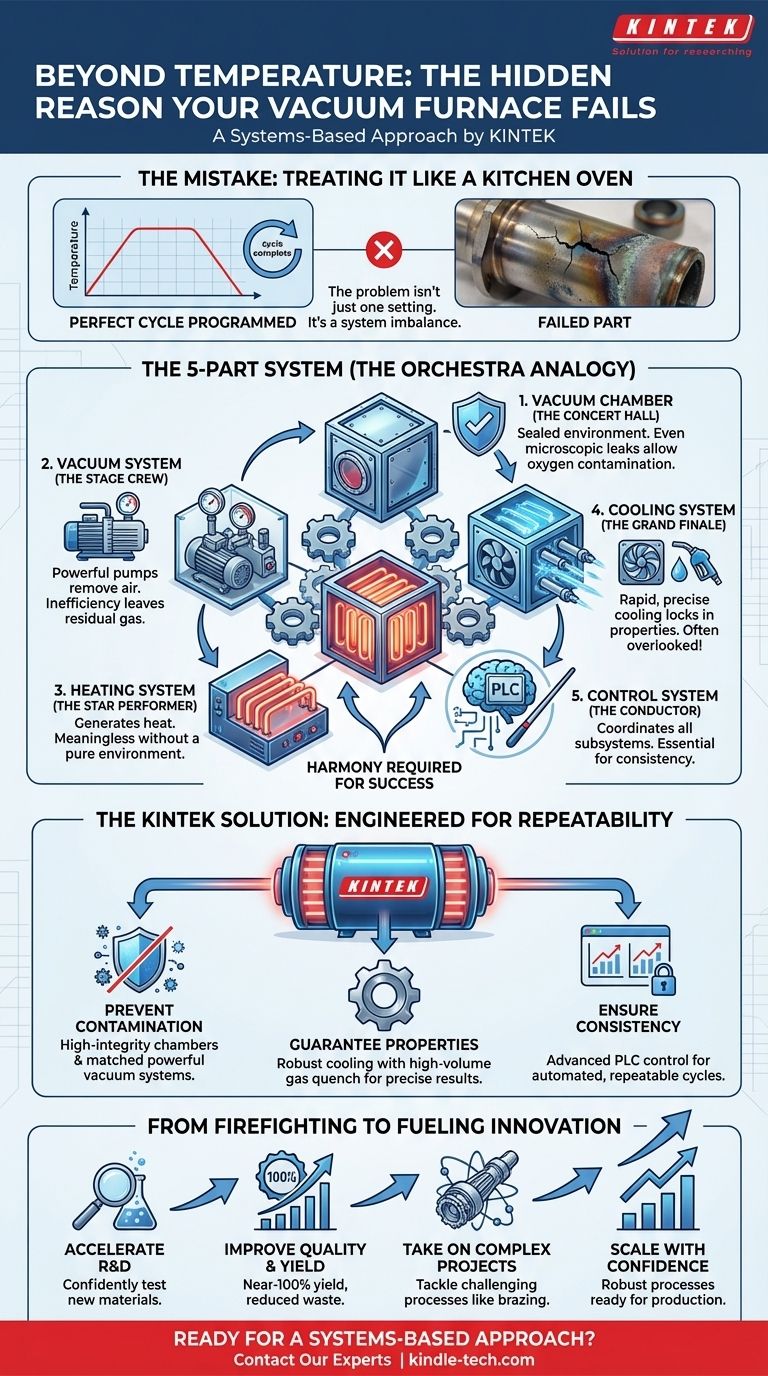

The Root Cause: Thinking of Your Furnace as an Oven

The fundamental mistake is treating a vacuum furnace like a simple kitchen oven—a box that just gets hot. It’s not.

A vacuum furnace is a complex, integrated system where five critical subsystems must work in perfect harmony. A failure in your part is almost never a problem with just one setting; it's a symptom of an imbalance in the system as a whole.

The Five-Part System That Really Runs the Show

Think of it as a five-person orchestra. If one instrument is out of tune or off-beat, the entire performance is ruined, no matter how skilled the other musicians are.

- The Vacuum Chamber (The Concert Hall): This is the sealed environment. Even a microscopic leak allows oxygen—the enemy of pure heat treatment—to seep in, causing the discoloration and contamination you're trying to avoid.

- The Vacuum System (The Stage Crew): These are the pumps that remove the air. If they are undersized or inefficient, they can't create a pure enough environment before the heat starts, leaving residual gases to react with your parts.

- The Heating System (The Star Performer): These are the elements that generate the heat. While critical, their performance is meaningless if the environment isn't pure.

- The Cooling System (The Grand Finale): This system is the most frequently overlooked hero. For many materials, achieving specific properties like hardness depends on cooling down at a very precise, rapid rate. A weak fan or poorly designed gas-quenching system will cause a slow, uneven cool-down, resulting in brittle or soft parts—even if the heating cycle was perfect.

- The Control System (The Conductor): This is the brain, coordinating the other four systems. An unsophisticated controller can't manage the complex interplay between pumping, heating, and cooling, leading to inconsistent results from one batch to the next.

This is why simply "turning up the heat" doesn't work. You're just asking one musician to play louder, ignoring the fact that the real problem is the out-of-tune instrument across the stage.

The Solution: A System, Not Just a Box

To achieve consistently perfect results, you don't need a better recipe. You need a better, more integrated instrument. You need a furnace that was designed from the ground up with the understanding that it is a complete processing environment.

This is where the engineering philosophy behind KINTEK laboratory equipment makes a decisive difference. We don't just sell a box that gets hot; we provide a balanced, high-performance system where every component is matched to deliver process repeatability.

How KINTEK Furnaces Are Engineered for Repeatability

Our equipment directly addresses the root causes of failure by ensuring all five subsystems work in concert.

- To Prevent Contamination: Our furnaces feature high-integrity vacuum chambers and powerful, matched vacuum systems that rapidly achieve and hold the deep vacuum levels necessary for processing sensitive, high-purity materials.

- To Guarantee Material Properties: We recognize that cooling is just as important as heating. Our furnaces are equipped with robust cooling systems, featuring high-volume gas quenching that delivers the rapid, uniform cooling rates needed to lock in the desired hardness and microstructure.

- To Ensure Consistency: Our advanced PLC-based control systems act as a precise conductor, offering programmable, automated control over every variable. This eliminates guesswork and ensures that the cycle you run today is identical to the one you run six months from now.

A KINTEK furnace isn't just a piece of hardware; it's a guarantee of process control, designed by experts who understand the intricate physics behind your work.

From Fighting Fires to Fueling Innovation

When you stop firefighting inconsistent batches and can finally trust your equipment, a remarkable shift happens. Your lab's potential is unlocked.

Instead of re-running the same process, your team can:

- Accelerate New Material R&D: Confidently test the thermal properties of next-generation alloys and composites, knowing that the furnace is a stable, reliable variable.

- Improve Product Quality and Yield: Move from an 80% success rate to near-100% yield, drastically reducing waste and increasing the profitability of each run.

- Take on More Complex Projects: Tackle challenging processes like the high-vacuum brazing of intricate medical or aerospace components, which were previously too risky.

- Scale with Confidence: Develop a robust, repeatable process in the lab that can be confidently scaled for larger production, knowing the underlying principles are sound.

Your vacuum furnace should be a tool that enables discovery, not a source of constant problems. It’s time to move beyond fixing individual failures and invest in a system that guarantees success.

Your project is unique. The requirements for annealing medical-grade titanium are vastly different from those for hardening tool steel. Our team can help you define the right integrated system for your specific application, ensuring your results are not just successful, but repeatable. Let's discuss the challenges you're facing and how a systems-based approach can solve them for good. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces