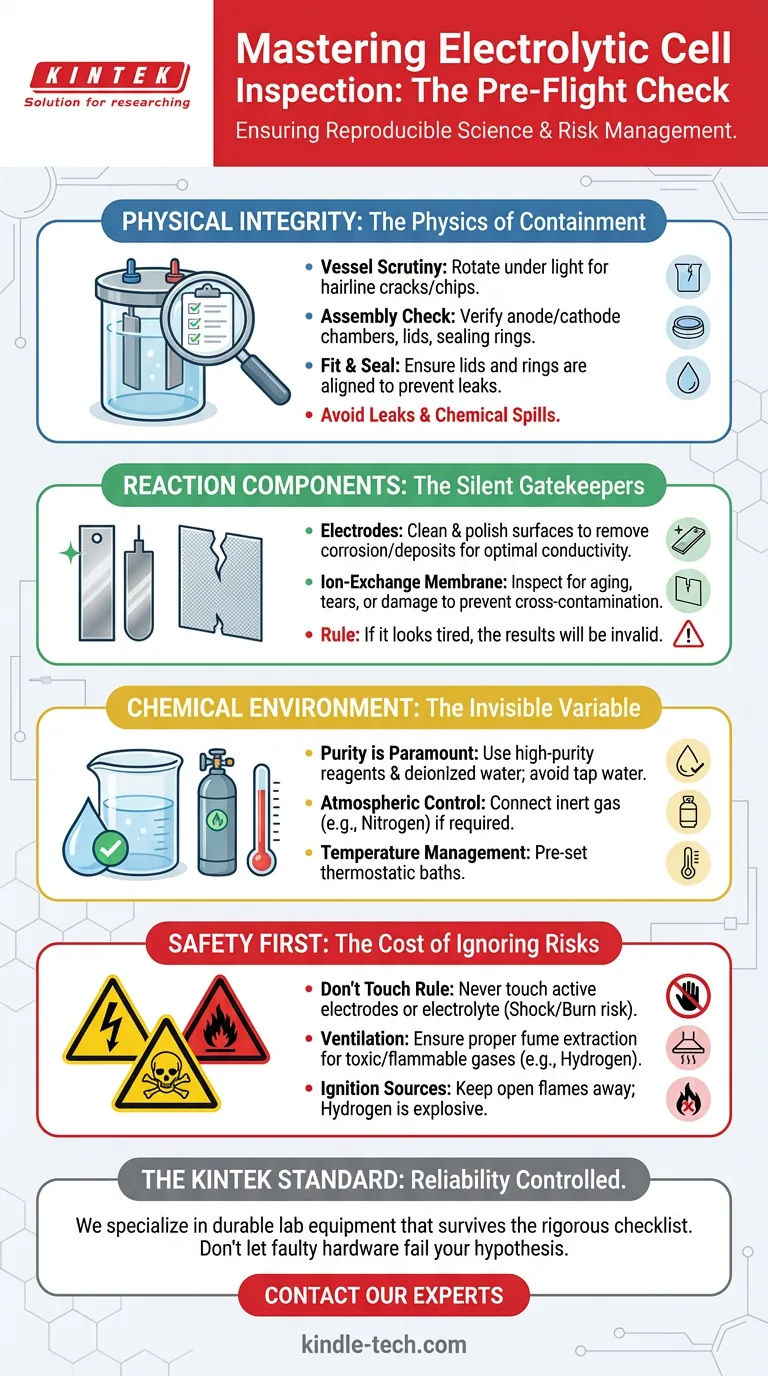

The Art of the Pre-Flight Check

In complex systems—whether it’s a Boeing 747 or a laboratory electrolytic cell—disaster rarely strikes because of a lack of knowledge. It strikes because of a lack of attention to the mundane.

We tend to obsess over the theoretical chemistry, the voltage parameters, and the expected yield. Yet, the success of an electrochemical experiment often hinges on something far more physical: the integrity of the glass, the cleanliness of a surface, and the seal of a lid.

A pre-use inspection is not merely a procedural chore. It is a ritual of risk management.

It is the foundational practice that separates reproducible science from dangerous guesswork.

The Physics of Containment

The cell body is the stage where the performance happens. If the stage is broken, the show cannot go on.

Glass is resilient, but it is not immortal. Before you pour a single drop of electrolyte, the vessel requires scrutiny. You are looking for the "silent culprits"—hairline cracks or microscopic chips.

A compromised cell body does two things, neither of them good:

- It leaks electrolyte, destroying your stoichiometry.

- It creates a safety hazard that transforms a controlled reaction into a chemical spill.

The Integrity Checklist

- The Vessel: Rotate the cell body under good light. Look for cracks.

- The Assembly: Verify the presence of anode and cathode chambers, lids, and sealing rings.

- The Fit: A mismatched lid or a dry sealing ring is a leak waiting to happen.

The Silent Gatekeepers

Once the vessel is verified, we move to the internal components. These are the parts that dictate the efficiency of the reaction.

The Electrodes

An electrode is only as good as its surface area.

Over time, corrosion and surface deposits build up, creating resistance where there should be conductivity. A dirty electrode doesn't just slow down the reaction; it alters the data.

Clean, polish, and inspect. You want a reactive surface, not a graveyard of past experiments.

The Ion-Exchange Membrane

This is the most delicate piece of the puzzle. The membrane separates the anode and cathode chambers, allowing only specific ions to pass.

If this membrane shows signs of aging, tears, or physical damage, you no longer have separation. You have cross-contamination.

The rule is simple: If the membrane looks tired, the results will be invalid.

The Invisible Environment

Chemistry is sensitive. It reacts to what we put in, but also to what we fail to keep out.

Purity is Paramount

Impurity is the enemy of precision. Using tap water or low-grade reagents introduces "rogue agents" into your cell—ions that trigger side reactions you didn't account for.

Always use high-purity reagents and deionized or distilled water.

The Atmosphere

Some reactions suffocate in oxygen; others require strict temperature control.

- Gas: If your experiment demands an inert atmosphere, ensure your nitrogen supply is connected and flowing.

- Heat: If temperature matters, pre-set your thermostatic water bath.

The Cost of Ignoring Safety

In electrochemistry, we combine two inherent risks: high-voltage electricity and conductive, often corrosive, liquids.

The margin for error is slim.

The "Don't Touch" Rule

Never touch electrodes or electrolyte during operation. The risk of electrical shock or chemical burns is immediate.

Managing the Breath of the Reaction

Electrolysis produces gas. Sometimes it is benign; often it is toxic or flammable (like Hydrogen).

- Ventilation: Ensure the fumes have somewhere to go.

- Ignition Sources: Hydrogen is explosive. Open flames have no place near an active cell.

Summary: The Pre-Use Protocol

Below is the condensed logic for ensuring a successful run.

| Category | The "Why" | Key Actions |

|---|---|---|

| Physical Integrity | Prevents leaks and breaks. | Check cell body for cracks; inspect seals and lids. |

| Reaction Components | Ensures electrical efficiency. | Polish electrodes; check membrane for tears/aging. |

| Chemical Environment | Prevents contamination. | Use high-purity reagents; control temp/atmosphere. |

| Safety | Prevents injury. | Ventilation; removal of ignition sources; no contact. |

The KINTEK Standard

Reliability is a variable you should be able to control.

At KINTEK, we understand that an engineer’s romance is found in equipment that works exactly as expected, every single time. We specialize in the lab equipment that survives the rigorous checklist—from durable cell bodies to high-purity consumables.

Don't let faulty hardware be the reason your hypothesis fails.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Super Sealed Electrolytic Electrochemical Cell

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

Related Articles

- The Symphony of Coefficients: Why Your Electrolytic Cell Cannot Be a Monolith

- The Architecture of Precision: Why the Invisible Details Define Electrochemical Success

- The Architecture of Precision: Mastering Electrolytic Cell Maintenance

- The Silent Variable: Engineering Reliability in Electrolytic Cells

- The Architecture of Precision: Mastering the Five-Port Water Bath Electrolytic Cell