It’s a familiar and frustrating moment in any foundry or lab: you pour the crucible, and you can see it instantly. The molten aluminum is sluggish, and a thick, grey scum of dross coats the surface. Despite your team’s best efforts, another batch is compromised. The alloy composition is questionable, the risk of inclusions is high, and the entire melt might have to be scrapped.

You’re left wondering: Was it the raw material? Did someone miscalculate the temperature? This single failure can set a project back by days, wasting expensive materials and valuable team hours.

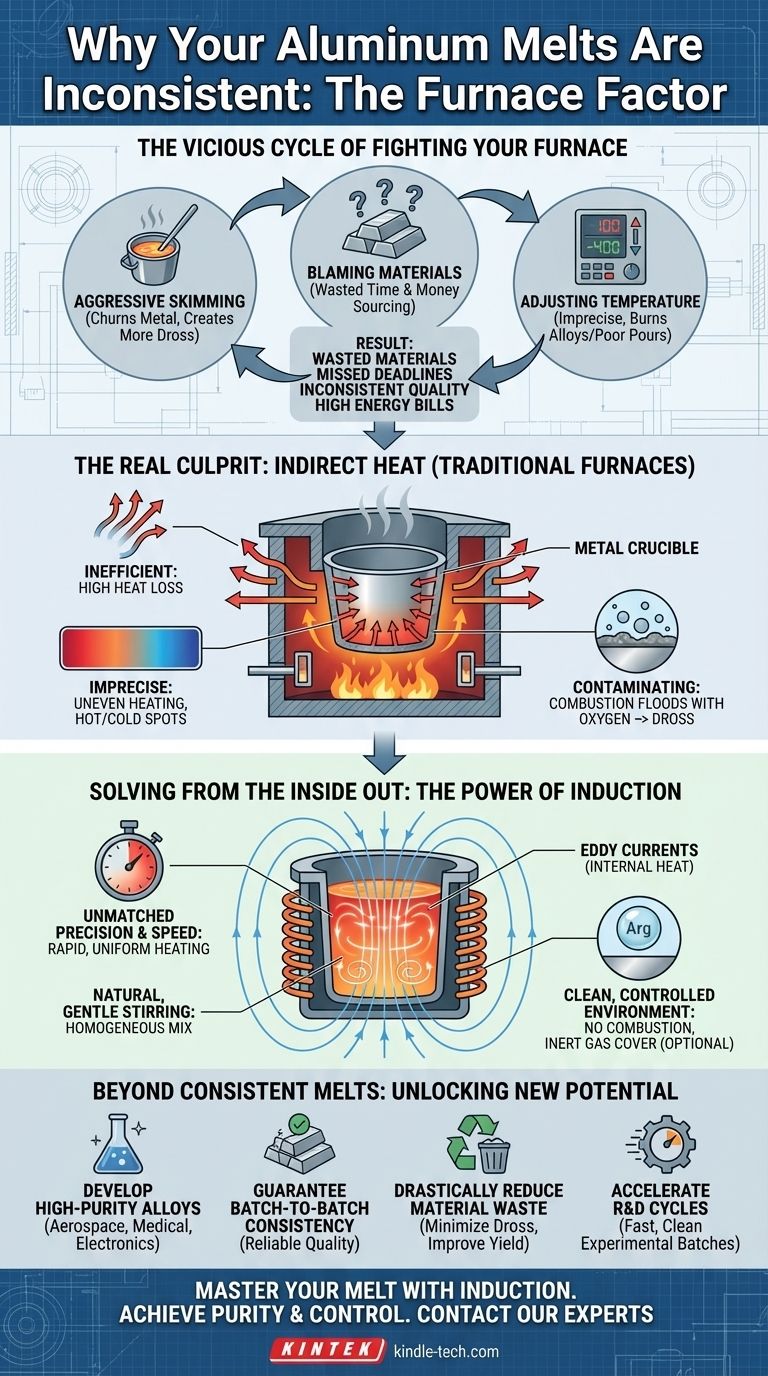

The Vicious Cycle of Fighting Your Furnace

If this scenario sounds familiar, you are not alone. It’s a widespread problem for anyone working with aluminum, a notoriously reactive metal. When faced with inconsistent melts, many labs and foundries fall into a predictable pattern of troubleshooting:

- Aggressive Skimming: You try to remove the dross (oxide layer) more vigorously, but this often just churns the molten metal, exposing more of it to air and creating even more dross.

- Blaming Materials: You question the quality of your aluminum ingots or scrap, spending time and money sourcing new materials, only to get the same poor results.

- Adjusting Temperature: You tweak the settings on your gas or resistance furnace, but the controls are imprecise. You either overshoot the temperature, burning off valuable alloying elements, or undershoot it, resulting in a poor pour.

These "solutions" are merely a reaction to the symptoms. The real cost isn't just a single failed melt; it's the accumulation of these issues. These struggles lead to serious business consequences: soaring material waste, missed project deadlines, unpredictable product quality, and sky-high energy bills from inefficient furnaces running for hours on end. You're stuck in a reactive loop, constantly fighting fires instead of perfecting your process.

The Real Culprit: How Your Furnace Heats

Here’s the turning point: The problem isn’t your team, your process, or your materials. The problem is your furnace. Specifically, it’s how traditional fuel-fired or resistance furnaces heat the aluminum.

Indirect Heat: An Open Invitation for Oxides

Traditional furnaces work by heating the crucible or chamber from the outside. The heat then slowly and unevenly soaks into the metal. Think of it like trying to cook a thick steak on a pan that’s only hot in the center; some parts get burned while others remain raw. This process is:

- Inefficient: A huge amount of heat energy is lost to the furnace walls and surrounding air, just like trying to boil water in a pot without a lid. You pay for energy that never even reaches the metal.

- Imprecise: It’s nearly impossible to maintain a perfectly uniform temperature throughout the entire molten bath. Hot spots can burn away expensive alloys, while cold spots can lead to lumps and inconsistencies.

- Contaminating: Most importantly, fuel-fired furnaces rely on combustion, which floods the environment with oxygen. Aluminum has an intense affinity for oxygen—it will pull it from the air to form aluminum oxide (dross). A traditional furnace essentially creates the perfect environment for the very contamination you’re trying to avoid.

This is why your previous efforts failed. Skimming dross is a losing battle because your furnace is actively creating more. Adjusting temperature is ineffective because the heat source is too blunt and uncontrollable. You are fighting a fundamental principle of chemistry and physics.

Solving the Problem from the Inside Out: The Power of Induction

To truly solve this, you need to stop heating the metal from the outside in. You need a method that heats the aluminum directly, uniformly, and in a controlled environment, cutting off the oxygen that fuels contamination.

This is precisely what an induction furnace is designed to do. It isn't just a different kind of heater; it's a fundamentally smarter way to melt aluminum that addresses the root cause of your problems.

An induction furnace uses a powerful, alternating magnetic field. This field passes through the crucible and generates electrical currents—known as eddy currents—directly inside the aluminum itself. The metal’s own electrical resistance causes it to heat up rapidly and evenly from within.

This "inside-out" heating method delivers three critical advantages:

- Unmatched Precision and Speed: Because heat is generated within the metal, you get incredibly fast, responsive, and uniform temperature control. The entire bath reaches the target temperature at the same time, eliminating the hot and cold spots that plague traditional furnaces.

- Natural, Gentle Stirring: The same magnetic fields that create heat also cause the molten metal to gently and continuously stir. This ensures any alloying elements are mixed in perfectly, guaranteeing a homogenous, consistent final product every single time.

- A Clean, Controlled Environment: With no combustion, the primary source of oxygen is eliminated. Induction furnaces can easily be operated with an inert gas cover (like argon), creating a protective blanket over the melt. This starves the aluminum of the oxygen it needs to form dross, dramatically increasing your metal yield and purity.

KINTEK’s induction furnaces are engineered for labs and foundries that demand this level of control. They are not just equipment; they are the embodiment of a solution designed from a deep understanding of the physics and chemistry of melting aluminum.

Beyond Consistent Melts: Unlocking New Potential

When you stop fighting your furnace and solve the root problem of inconsistency and contamination, you don't just fix a nagging issue—you unlock entirely new capabilities.

With the clean, precise, and repeatable performance of an induction furnace, you can now:

- Develop High-Purity Alloys: Confidently create advanced aluminum alloys for demanding industries like aerospace, medical, and electronics, where even trace impurities are unacceptable.

- Guarantee Batch-to-Batch Consistency: Deliver the exact same quality to your clients every single time, building a reputation for unparalleled reliability.

- Drastically Reduce Material Waste: By minimizing dross formation, you can cut material losses by a significant margin, directly improving your bottom line.

- Accelerate R&D Cycles: Quickly and cleanly melt small, experimental batches to test new alloy formulations without the risk of cross-contamination between melts.

Ultimately, mastering your melt is about moving from a position of uncertainty to one of control. It’s about transforming your lab from a place of reactive problem-solving into a hub of proactive innovation.

Your challenges with aluminum are unique, from specific alloy requirements to production scale. Our team of experts can help you move past inconsistent results and achieve the purity and control your projects demand. To discuss how the right melting technology can transform your work, Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

Related Articles

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- Why Your High-Temperature Furnace Failed—And How to Prevent It From Happening Again

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures

- Beyond Heat: The Tube Furnace as a Controlled Micro-Environment