Your experiment has been running for 12 hours, holding steady at 1100°C. Weeks of preparation, sample synthesis, and careful setup all culminate in this final, critical heating stage. Then, you hear it—a sharp, sickening crack from the furnace. It’s the sound of catastrophic failure. The sound of your sample destroyed, your timeline shattered, and your data lost forever.

The Dragon in the Lab: Why Do Furnace Tubes Suddenly Fail?

For researchers in materials science, chemistry, and engineering, the tube furnace is a workhorse. Yet, it harbors a persistent and costly dragon: sudden tube failure. This isn't a random accident; it's a predictable outcome of intense physical and chemical stresses. A tube burst is the final cry of a component pushed beyond its limits.

The "dragon" of catastrophic failure has four primary forms of attack:

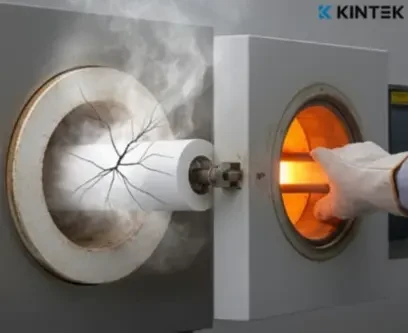

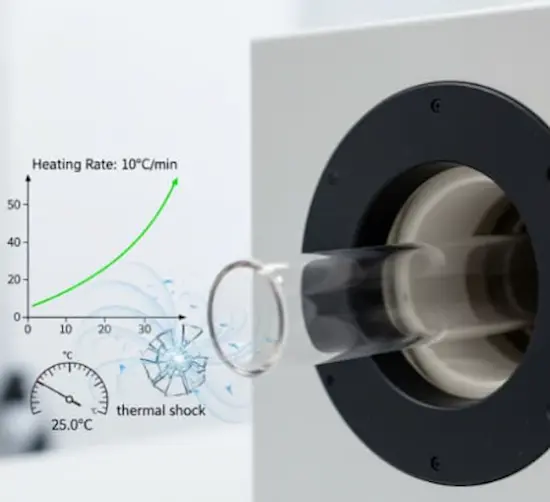

- Thermal Shock: This is the most common culprit, responsible for an estimated 80% of failures. Rapid heating or cooling—or worse, opening the furnace door at high temperatures—creates a massive temperature differential. The material cannot expand or contract uniformly, generating immense internal stress that results in cracking.

- Material Mismatch: A furnace tube is not just a pipe; it's a highly specific technical component. Using a quartz tube above its 1200°C limit or exposing it to strong alkaline substances is a recipe for disaster. Similarly, a corundum tube can lose its integrity if exposed to long-term moisture. Each material has a clear "no-go zone" of temperature and chemical compatibility.

- Mechanical Stress: A hidden flaw can become a fatal weakness under heat and pressure. This can be an invisible micro-crack from a slight knock during sample loading or uneven pressure from an over-tightened flange. These stress points become the epicenter of a failure.

- Chemical Corrosion: Corrosive gases like HCl or molten sample leakage can silently eat away at the tube's inner wall. This thinning process drastically reduces the tube's structural integrity until it can no longer withstand the operational pressure and heat.

The Hero's Breakthrough: A Proactive Strategy to Slay the Dragon

The breakthrough isn't a new discovery, but a fundamental shift in mindset: moving from reacting to failures to proactively preventing them. Successful scientists treat their furnace tube not as a disposable consumable, but as a critical piece of precision equipment. Their victory is built on a disciplined, three-part strategy.

Pillar 1: Choose Your Weapon Wisely

The battle is often won before the furnace is even turned on. The hero understands that matching the tube material to the specific application is non-negotiable. They meticulously check that the material (e.g., high-purity quartz, corundum, alumina) is rated for their target temperature, is inert to their specific samples and gases, and meets the purity requirements of their experiment.

Pillar 2: Master the Art of Thermal Control

The hero tames the beast of thermal shock through strict operational discipline.

- Heating: They implement controlled heating ramps (e.g., ≤10°C/min for quartz, ≤15°C/min for corundum), allowing the material to expand evenly. "One-click, full-power" heating is strictly forbidden.

- Cooling: They respect the critical natural cooling phase. The furnace door remains closed until the temperature falls well below 200°C. They know that forced cooling with a fan is a surefire way to shatter a tube and ruin a day's work.

Pillar 3: Practice Meticulous Handling and Maintenance

The hero knows that small details prevent big disasters.

- Installation: Flanges are tightened evenly in a diagonal pattern to distribute pressure, preventing localized stress points.

- Sample Loading: Long-handled tools are used to place samples gently, avoiding any contact that could create micro-cracks on the tube's surface.

- Inspection: Before every run, a quick visual inspection for scratches, cloudiness, or residual contamination is performed. They know that starting an experiment with a compromised tube is a false economy.

The Magic Sword: The Critical Tool That Makes This Strategy Possible

This shift from reactive repair to proactive victory is only possible when you have a tool you can trust. The entire strategy hinges on starting with a furnace tube that is flawlessly engineered and perfectly suited for the task. This is where the right component becomes the hero's magic sword.

A high-quality furnace tube from a reliable supplier like KINTEK isn't just a piece of quartz or ceramic; it's your first and best line of defense.

- Against Thermal Shock: Our tubes are manufactured from high-purity materials with superior thermal stability, providing a wider margin of safety against the temperature gradients that cause 80% of failures.

- Against Material Mismatch: Choosing the right material shouldn't be guesswork. We provide clear specifications and expert support to help you match the right tube to your specific chemistry and temperature profile, eliminating failure by incompatibility from the start.

- Against Mechanical Stress: A hidden crack is a ticking time bomb. Our furnace tubes undergo stringent quality control to ensure they are free from the microscopic defects, internal stresses, and dimensional inconsistencies that lead to catastrophic failure under heat and pressure.

The New World: Beyond Prevention to Accelerated Innovation

When you eliminate the threat of sudden tube failure, you do more than just save a single experiment. You create a more efficient, reliable, and innovative research environment.

With dependable furnace components, your lab gains predictable timelines, uncompromised data integrity, and the confidence to push the boundaries of your research. Instead of budgeting for constant replacements and downtime, you can invest in progress. You move from a state of hoping your equipment survives to knowing it will perform, allowing your team to focus on what truly matters: discovery.

Your materials, your temperatures, your gases—every experiment is unique. Don't leave the integrity of your research to chance by using a generic or substandard component in your most critical processes. Let's discuss the specific challenges of your project and equip you with the right tools for guaranteed success.

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

Related Articles

- Entropy and the Alumina Tube: The Art of Precision Maintenance

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Your Tube Furnace Is Not the Problem—Your Choice of It Is

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- The Silent Partner in Pyrolysis: Engineering the Perfect Thermal Boundary