Your synthesis experiment has been running for 12 hours. The materials are novel, the budget is tight, and this data is critical for your next publication. But when you open the furnace, you find the samples are completely oxidized—useless. Weeks of preparation and valuable materials are lost, all because of a single, fundamental misunderstanding: assuming any high-temperature furnace would do the job.

The Hidden Risk: When a 'Hot Box' Isn't Just a 'Hot Box'

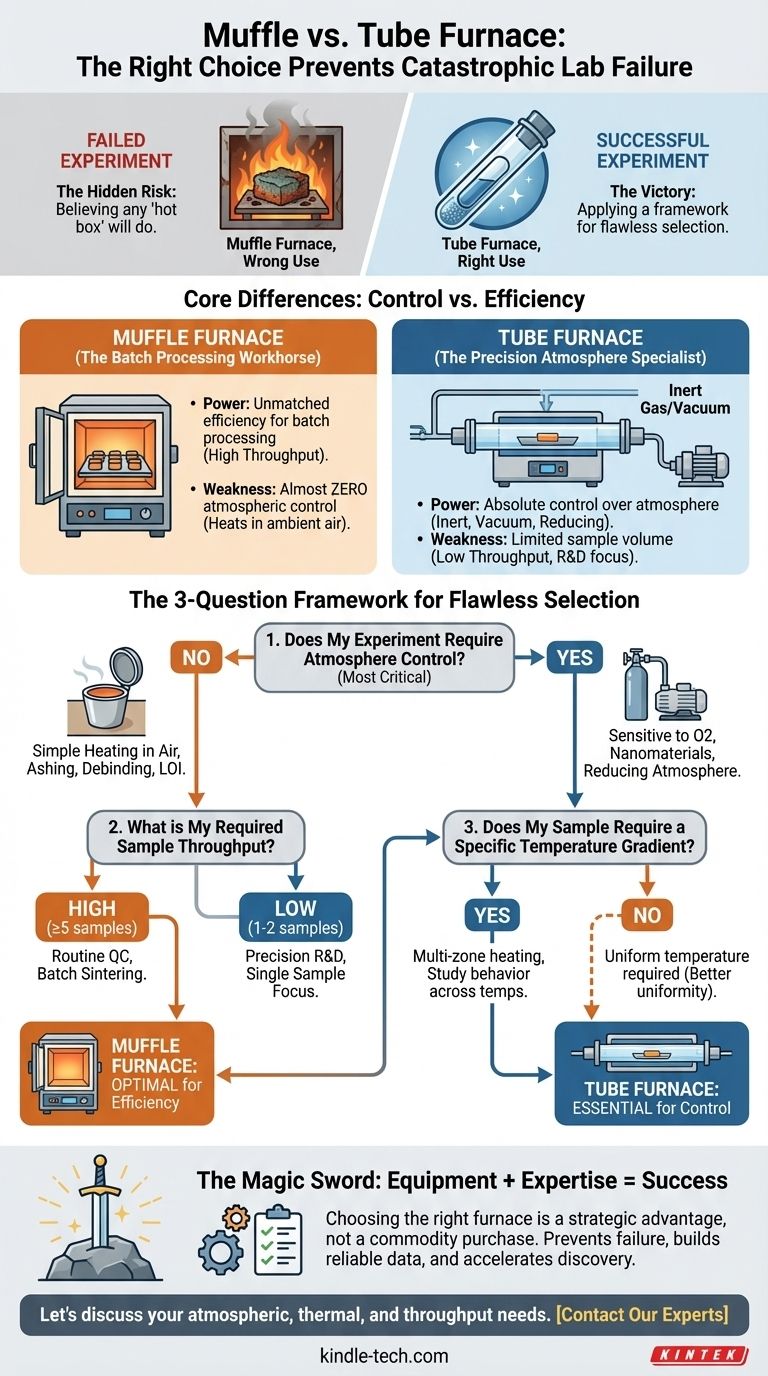

At first glance, muffle furnaces and tube furnaces seem to serve the same purpose: they get very hot. This oversimplification is a dangerous trap that leads to failed experiments, wasted resources, and compromised data. The "dragon" in the lab isn't a complex chemical reaction; it's the catastrophic failure that stems from choosing the wrong tool for a critical heating process.

The fundamental difference isn't about maximum temperature; it's about control over the experimental environment.

The Muffle Furnace: The Batch Processing Workhorse

Think of a muffle furnace (or box furnace) as a sophisticated high-temperature oven. Its core strength lies in its spacious, insulated chamber where heating elements work to create a uniform temperature field. You open the door, load multiple samples on a tray, and heat them all simultaneously in the ambient air.

- Its Power: Unmatched efficiency for batch processing.

- Its Weakness: Almost zero atmospheric control. What you put in is heated in the air that's already there.

The Tube Furnace: The Precision Atmosphere Specialist

A tube furnace operates on a completely different principle. The sample is placed inside a narrow ceramic or quartz tube, which is then heated from the outside. The ends of the tube can be sealed and connected to vacuum pumps and gas lines. This design transforms it from a simple heater into a highly controlled micro-environment.

- Its Power: Absolute control over the atmosphere (inert gas, vacuum, reducing gases).

- Its Weakness: Limited sample volume, typically processing one small crucible or boat at a time.

The Breakthrough Moment: A 3-Question Framework for Flawless Selection

The hero of this story is the researcher who avoids experimental failure by making an informed choice. The victory comes not from a complex new discovery, but from applying a simple, powerful decision-making framework. Before you select your next furnace, ask these three critical questions.

1. Does My Experiment Require Atmosphere Control?

This is the most important question. If the answer is yes, the choice is made for you.

- YES: You are performing a reaction that is sensitive to oxygen, such as synthesizing nanomaterials, annealing reactive metal alloys (like titanium or magnesium), or conducting experiments in a reducing atmosphere (using hydrogen gas). You absolutely need a Tube Furnace. Using a muffle furnace will result in immediate oxidation and complete failure.

- NO: Your goal is simple heating in air, like determining the ash content of a food sample (ashing), removing binders from a ceramic part (debinding), or performing a loss-on-ignition (LOI) test on soil. A Muffle Furnace is the more efficient and cost-effective choice.

2. What is My Required Sample Throughput?

This question is about balancing precision with efficiency.

- High Throughput (≥5 samples at once): You are running routine quality control tests or preparing multiple material samples for sintering that are not air-sensitive. The large chamber of a Muffle Furnace is designed for this kind of batch work.

- Low Throughput (1-2 samples at a time): Your experiment is focused on research and development, where precise control over a single sample is more important than volume. A Tube Furnace is the right tool.

3. Does My Sample Require a Specific Temperature Gradient?

Sometimes, it's not just about a single temperature, but how temperature changes across the sample.

- YES: You need to study how a material behaves across a range of temperatures simultaneously (e.g., chemical vapor deposition). A multi-zone Tube Furnace is specifically designed to create and hold precise temperature gradients along the length of the tube.

- NO: You simply need your entire sample to be held at one uniform temperature. A Muffle Furnace provides excellent thermal uniformity throughout its entire chamber.

The Magic Sword: The Right Equipment, Guided by Expertise

This framework reveals a critical truth: a furnace is not a commodity. It is a strategic instrument, and choosing the right one is the "magic sword" that enables experimental success. A muffle furnace is the perfect tool for high-volume ashing, but it's a guaranteed failure for synthesizing carbon nanotubes. A tube furnace is essential for vacuum annealing, but it's an inefficient bottleneck for routine material sintering.

At KINTEK, we don't just supply lab equipment; we provide the expertise to ensure the instrument you acquire is precisely aligned with your scientific mission. We've seen firsthand how applying this simple, logical framework prevents costly errors and accelerates research. Our role is to help you translate your experimental needs—atmosphere, throughput, and thermal profile—into the most effective and reliable heating solution.

From Choosing a Furnace to Accelerating Discovery

Making the right choice between a muffle and tube furnace does more than just prevent one failed experiment. It builds a foundation of reliable, repeatable data. It saves countless hours of wasted work, protects your budget from unnecessary material loss, and ultimately shortens the path from hypothesis to discovery. By moving beyond a simple "spec sheet" comparison and focusing on the core requirements of your application, you transform a simple equipment purchase into a strategic advantage for your entire lab.

The framework above is a powerful starting point, but every research project has unique challenges. If your work involves complex thermal profiles, reactive materials, or specific throughput goals, a deeper conversation is often the key to unlocking the best possible outcome. Let's discuss the specific atmospheric, thermal, and throughput requirements of your next project. Contact Our Experts

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Entropy and the Alumina Tube: The Art of Precision Maintenance

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- Why Your Furnace Components Keep Failing—And the Material Science Fix

- Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters