The Illusion of 'Just Heating'

In many fields, applying heat is a crude act. You turn a dial, things get hot, a change occurs.

But in material science, this is a dangerous oversimplification. For the researcher synthesizing a novel semiconductor or annealing a delicate crystal, heat is not a blunt instrument; it is a parameter of exquisite sensitivity. The real goal is not merely to heat a sample, but to eliminate every other variable that could corrupt the outcome.

Uncontrolled atmosphere is a variable. Temperature gradients are variables. Contaminants are variables.

This is the psychological core of advanced thermal processing: the relentless pursuit of control. A tube furnace is not just a heating device; it is a tool for creating a predictable, isolated universe for a sample.

An Elegant Geometry for Unwavering Control

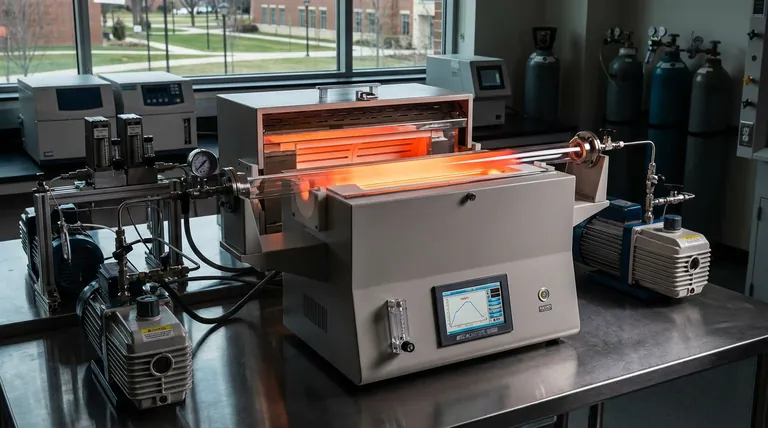

The power of a tube furnace stems from its simple, elegant design. Its cylindrical form is a direct answer to the fundamental challenges of thermal and atmospheric precision.

The Certainty of 360-Degree Heat

Imagine trying to grow a perfect single crystal. A temperature fluctuation of just a few degrees across its surface—a "hot spot"—can introduce a defect, a subtle flaw in the crystal lattice that cascades into total failure of its electronic properties.

A box furnace, with elements on its walls, inevitably creates gradients. A tube furnace, by arranging its heating elements circumferentially around the process tube, provides 360-degree heating.

This isn't a minor feature; it is an insurance policy against thermal imperfection. It ensures the sample experiences the same temperature from all sides, creating a zone of thermal uniformity that is the bedrock of repeatable, high-quality results.

Mastering the Invisible: Atmosphere as a Reagent

Now imagine you're synthesizing a material that cannot tolerate oxygen. In a standard furnace, every oxygen molecule in the ambient air is not an inert bystander; it is a reactive contaminant poised to ruin your multi-day experiment.

The tube furnace solves this by being a fundamentally sealed system. By fitting flanges to the ends of the tube, you can first pull a vacuum to evacuate unwanted air and moisture. Then, you can introduce a specific, high-purity gas like argon or nitrogen.

Suddenly, the atmosphere is no longer a source of contamination. It has become a precisely controlled reagent in your process, enabling the creation of materials that would be impossible to form in the open air.

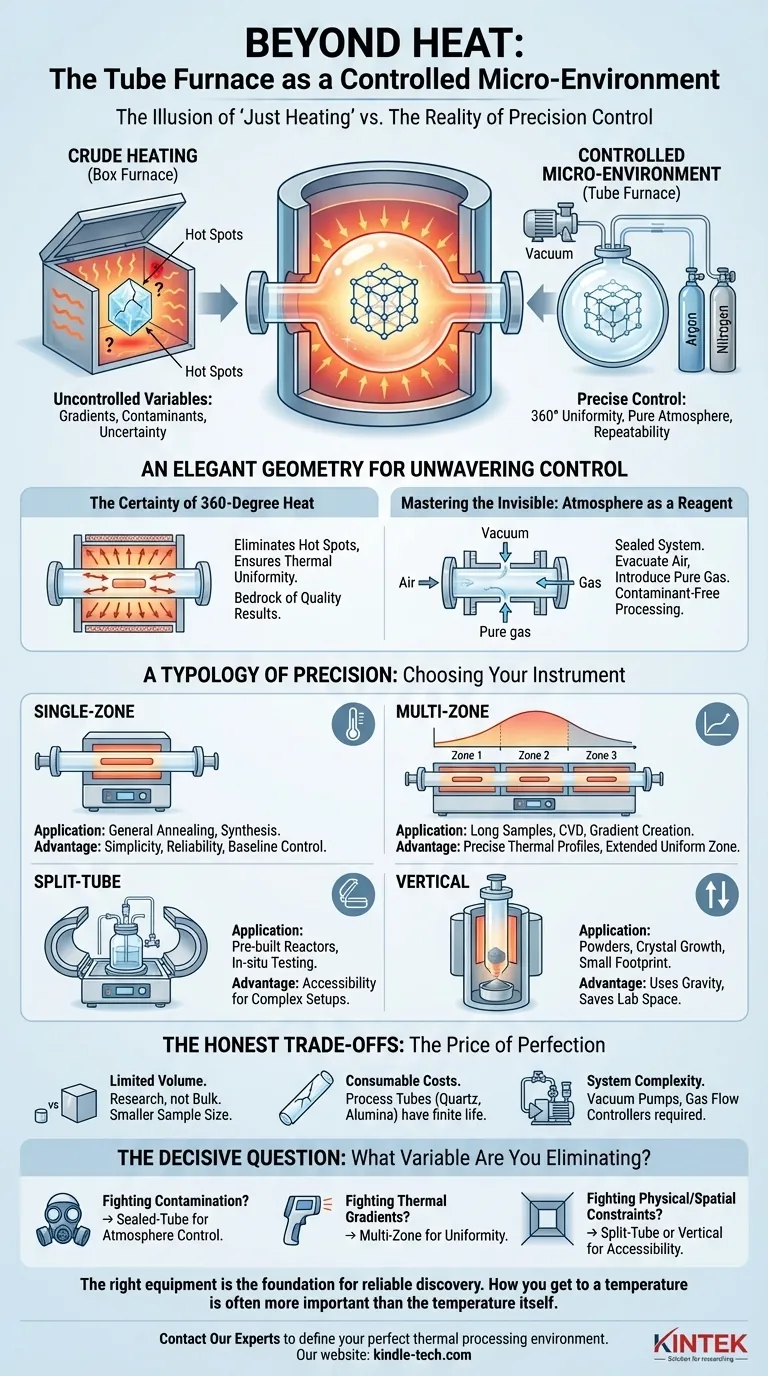

Choosing Your Instrument: A Typology of Precision

Just as a surgeon has different scalpels for different procedures, the material scientist has different tube furnaces tailored to specific tasks. The choice is a reflection of the experimental goal.

| Furnace Type | Primary Application | Key Advantage |

|---|---|---|

| Single-Zone | General purpose annealing, synthesis | Simplicity and reliability for uniform heating. |

| Multi-Zone | Long samples, gradient creation (CVD) | Extends the uniform hot zone or creates a specific thermal profile. |

| Split-Tube | Using pre-built reactors, in-situ testing | Hinged design allows placing the furnace around an existing setup. |

| Vertical | Processing powders, crystal growth, small footprint | Uses gravity to its advantage and saves valuable lab space. |

The decision moves from the general to the specific. A single-zone furnace from a trusted supplier like KINTEK provides the baseline of control for most standard applications.

But for more complex work, like chemical vapor deposition where you need reactants to decompose at specific points along the tube, a multi-zone furnace becomes a sculptor's tool, allowing you to create precise temperature gradients.

When the challenge is logistical—like heating a complex, sealed quartz reactor that cannot be slid into a tube—the brilliantly pragmatic split-tube furnace opens up to accommodate it. And in a crowded lab, the small footprint and ergonomic loading of a vertical furnace is an elegant solution.

The Honest Trade-Offs: The Price of Perfection

There is no free lunch in engineering, and the precision of a tube furnace comes with inherent trade-offs. To choose this tool is to accept its costs in pursuit of a higher goal.

-

Limited Volume: The price of uniformity is a smaller sample size. The internal diameter of the process tube inherently limits throughput. This is a tool for research and development, not bulk production.

-

Consumable Costs: The process tubes, whether quartz or high-purity alumina, are the heart of the system but also consumables. They are susceptible to thermal shock and have a finite lifespan, representing a necessary operational cost.

-

System Complexity: Achieving true atmospheric control requires more than the furnace. It requires a system: vacuum pumps, gas flow controllers, and secure flange assemblies. This complexity is the price of eliminating atmospheric uncertainty.

The Decisive Question: What Variable Are You Eliminating?

Ultimately, selecting the right furnace comes down to a single question: What variable represents the greatest threat to your experiment's success?

- Are you fighting contamination? Your non-negotiable need is the sealed-tube design for atmosphere control.

- Are you fighting thermal gradients? Your priority is a multi-zone furnace for the highest degree of temperature uniformity.

- Are you fighting physical or spatial constraints? Your answer lies in the accessibility of a split-tube or the efficiency of a vertical furnace.

The tube furnace is a testament to an engineering truth: in the quiet pursuit of new materials, how you get to a temperature is often more important than the temperature itself. The right equipment isn't an expense; it's the foundation upon which reliable discovery is built.

If your research demands the elimination of uncertainty for repeatable, high-fidelity results, our team can help you define the perfect thermal processing environment. Contact Our Experts

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- Why Your High-Temperature Furnace Failed—And How to Prevent It From Happening Again

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- Installation of Tube Furnace Fitting Tee

- Your Tube Furnace Is Not the Problem—Your Choice of It Is