Does this sound familiar? A batch of meticulously machined metal components, perfect down to the last micron, goes into the heat treatment furnace. Hours later, it comes out a collection of expensive disappointments. The surface is dull and scaled. Critical dimensions have shifted. The parts that were once perfect are now out of tolerance, destined for the scrap bin or a costly rework process.

You’ve invested heavily in state-of-the-art CNC machines and skilled operators, yet this final, crucial step feels like a game of chance.

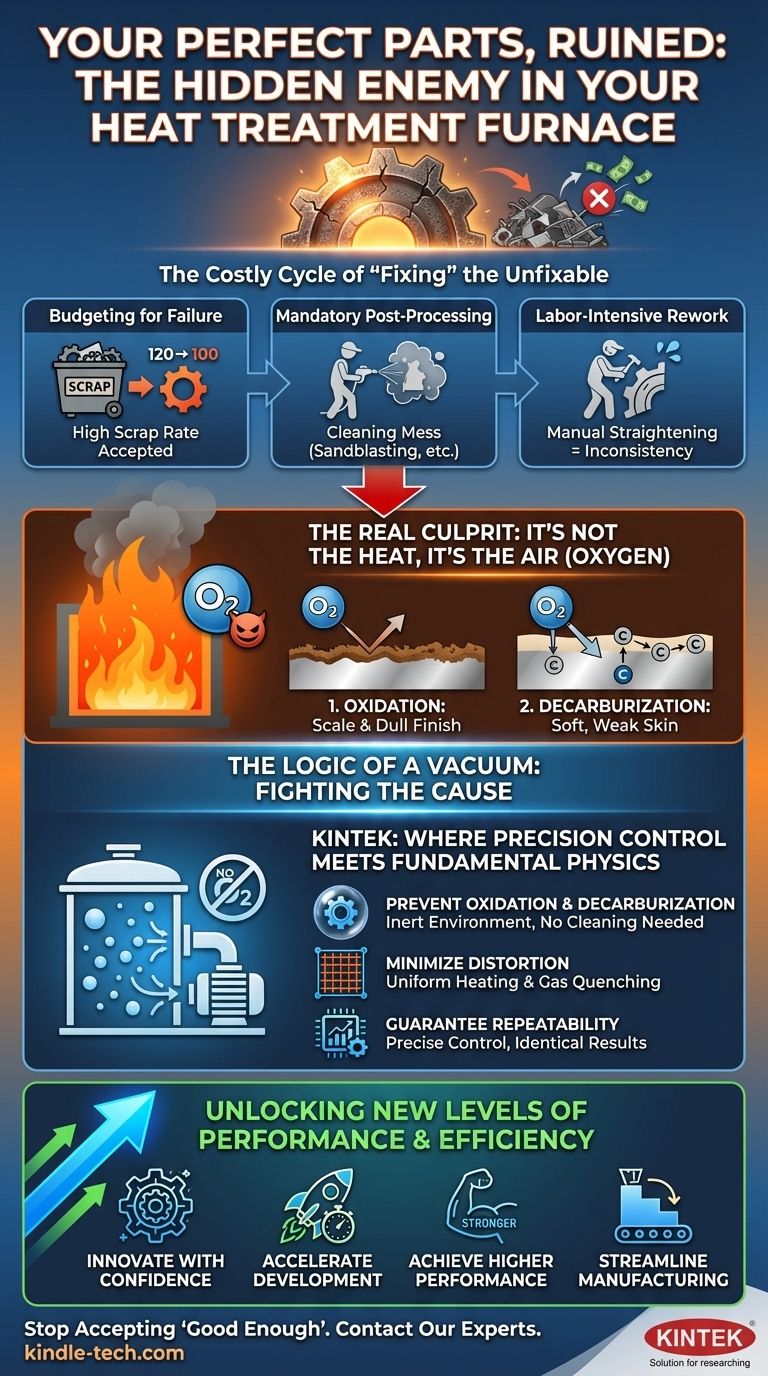

The Costly Cycle of "Fixing" the Unfixable

For many high-precision industries, this scenario isn't an occasional accident; it's a chronic headache accepted as a "cost of doing business." To compensate, teams fall into a predictable and expensive routine:

- Budgeting for Failure: Manufacturing plans intentionally include a high scrap rate. You might produce 120 parts just to get 100 that pass quality control.

- Mandatory Post-Processing: Secondary operations like sandblasting, grinding, or acid pickling are built into the workflow, not as an option, but as a necessity to clean up the mess left by the furnace.

- Labor-Intensive Rework: Technicians spend countless hours attempting to straighten warped components, a manual process that introduces its own inconsistencies.

These are not solutions. They are workarounds that mask a deeper problem, and they have severe business consequences. Project timelines stretch, production costs inflate, and most critically, the final product's reliability is compromised. You can't be certain if a component is truly optimal or just one that was "rescued" from failure.

The Real Culprit: It’s Not the Heat, It’s the Air

Here is the turning point. What if these issues—the scaling, the warping, the inconsistency—are not inevitable side effects of heat? What if they are all symptoms of a single, identifiable cause?

The fundamental problem isn't the high temperature. It's the oxygen in the furnace atmosphere.

At hardening temperatures, steel is highly reactive. When exposed to a standard atmosphere, two destructive chemical reactions occur:

- Oxidation: The iron in the alloy reacts with oxygen to form a brittle layer of scale on the surface. This is what ruins the clean, bright finish of your machined part and requires aggressive cleaning.

- Decarburization: The carbon—the very element that gives steel its hardness—is literally pulled from the surface layer as it reacts with oxygen. This creates a soft, weak "skin" on the component, compromising its strength and wear resistance.

The common solutions fail because they only deal with the aftermath. Grinding removes the scale but doesn't restore the lost carbon. Straightening a warped part doesn't fix the internal stresses that caused the warp in the first place. You are treating the symptoms, while the disease runs rampant every time you heat a new batch.

Fighting the Cause, Not the Symptom: The Logic of a Vacuum

If the presence of oxygen is the root cause, the only true solution is to remove it from the equation entirely.

This is the simple but profound principle behind vacuum hardening. By performing the heat treatment process in a chamber pumped down to a near-perfect vacuum, you eliminate the oxygen required for those destructive reactions to happen.

This isn't just a minor improvement; it's a fundamental shift in the process. To achieve this, you need more than just a hot box. You need an instrument engineered for absolute environmental control.

KINTEK: Where Precision Control Meets Fundamental Physics

This is where a tool designed with a deep understanding of the problem becomes essential. KINTEK's advanced vacuum furnaces are not merely ovens; they are precision instruments engineered to solve the core challenges of heat treatment.

- To Prevent Oxidation and Decarburization: Our high-performance vacuum systems create a chemically inert environment. Parts emerge from the furnace as clean and bright as when they went in, with their surface chemistry perfectly preserved. This completely eliminates the need for post-process cleaning.

- To Minimize Distortion: Traditional furnaces heat unevenly, creating hot and cold spots that cause internal stresses and lead to warping. KINTEK furnaces are designed for exceptional temperature uniformity, ensuring the entire part heats and cools at the same controlled rate. This, combined with high-pressure gas quenching, minimizes distortion and keeps your parts within their specified tolerances.

- To Guarantee Repeatability: The entire vacuum hardening cycle—from pump-down and heating ramp to soak and quench—is managed by precise computer control. This locks in the process, delivering identical metallurgical results batch after batch, year after year.

Our equipment is the embodiment of the solution: it directly targets and eliminates the root cause of failure, transforming an unpredictable art into a reliable science.

Beyond a Simple Fix: Unlocking New Levels of Performance and Efficiency

When you stop fighting the symptoms of poor heat treatment, you don't just save money on scrap and rework. You unlock entirely new possibilities for your business.

With a reliable, predictable hardening process, you can:

- Innovate with Confidence: Engineers can design more complex, thin-walled, or intricate components without fearing they will be distorted in the furnace.

- Accelerate Product Development: R&D labs can get reliable material property data on the first try, dramatically shortening testing and validation cycles.

- Achieve Higher Performance: By ensuring a refined grain structure and uniform hardness, you can build products that are stronger, tougher, and more fatigue-resistant—critical for aerospace, medical, and other mission-critical applications.

- Streamline Manufacturing: By removing entire steps from your production line (like sandblasting or straightening), you can significantly shorten your total lead time and deliver products to market faster.

Solving this old, nagging problem doesn't just bring you back to zero; it propels you forward. It transforms a manufacturing bottleneck into a competitive advantage.

It’s time to stop accepting "good enough" from your heat treatment process. If your work demands precision before the furnace, it deserves predictability after. Let's discuss how to move beyond fixing problems and start building new possibilities for your projects. Contact Our Experts.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

Related Articles

- Ultimate Guide to High Pressure Tube Furnaces: Applications, Types, and Benefits

- Materials Science with the Lab Vacuum Furnace

- Introducing the Lab Vacuum Tube Furnaces

- The Versatility of Tube Furnaces: A Guide to Their Applications and Benefits

- High Pressure Tube Furnace: Applications, Safety, and Maintenance