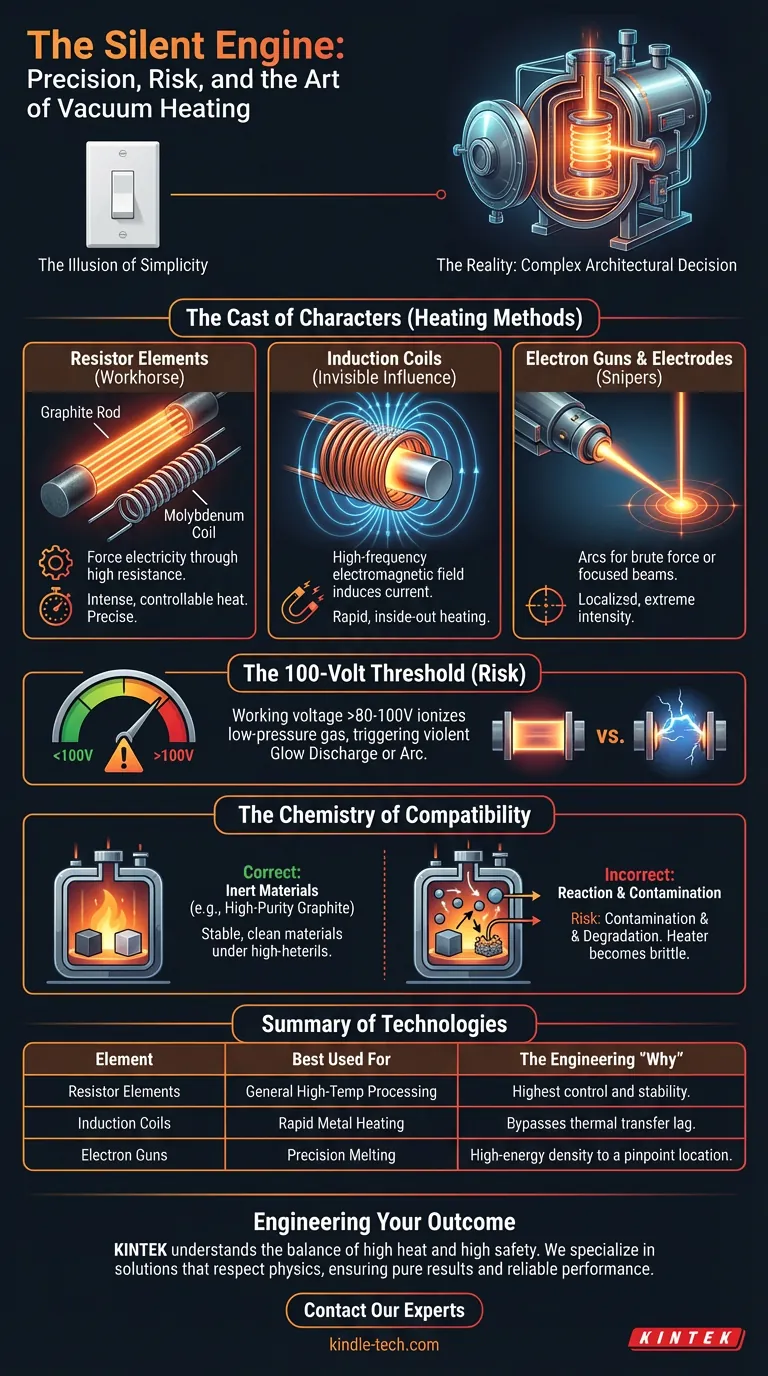

The Illusion of Simplicity

In laboratory engineering, we often mistake the generation of heat for a simple input. You flip a switch, energy flows, and temperature rises.

But in the unforgiving environment of a vacuum furnace, heat is not just an input. It is a complex architectural decision.

The heating element is the heart of the system. It dictates not only how hot the furnace gets, but the purity of the environment, the uniformity of the process, and the safety of the operator.

It is a classic trade-off between physics and material science. If you choose the wrong element, you don't just get poor results; you risk catastrophic system failure.

The Cast of Characters

To manipulate materials at the molecular level, we rely on three primary methods of energy transfer. Each has a specific "personality" and utility.

1. Resistor Elements

This is the workhorse of the industry. We force electricity through materials with high resistance—typically graphite or molybdenum.

The material resists the flow, creating friction at an atomic level, which manifests as intense, controllable heat. It is a method defined by struggle, yet it yields incredible precision.

2. Induction Coils

This is the method of "invisible influence."

Here, a coil generates a high-frequency electromagnetic field. It induces a current directly inside the conductive workpiece. The material heats from the inside out. It is rapid, efficient, and elegant, ideal for metals that need to reach temperature quickly.

3. Electrodes and Electron Guns

These are the snipers of the heating world.

Electrodes create arcs for brute-force melting. Electron guns fire focused beams of high-energy electrons at specific targets. They are used when the application demands localized, extreme intensity rather than a warm embrace.

The 100-Volt Threshold

There is a fascinating constraint in vacuum furnace design that often surprises non-engineers: The Voltage Limit.

You might assume that more power requires higher voltage. But inside a vacuum, physics plays by different rules.

If the working voltage exceeds 80 to 100 volts, the low-pressure gas remaining in the chamber can ionize.

This triggers a glow discharge or arc.

Instead of heating your sample, the electricity jumps the gap, attacking the insulation and the furnace walls. It is a violent, uncontrolled event.

Good engineering is about respecting this limit. It is about designing elements that deliver massive power without ever crossing that voltage threshold where the atmosphere turns against you.

The Chemistry of Compatibility

Heat accelerates chemistry. In a vacuum, this acceleration is magnified.

The most common failure mode isn't mechanical breakage; it is chemical incompatibility.

If your heating element reacts with your workpiece, two things happen:

- Contamination: Your sample is ruined by atoms migrating from the heater.

- Degradation: The heater itself becomes brittle and fails prematurely.

Process purity requires selecting materials—like high-purity graphite or refractory metals—that remain chemically inert, even when the rest of the world is melting.

Summary of Technologies

Selecting the right engine for your furnace is about matching the tool to the task.

| Heating Element Type | Best Used For | The Engineering "Why" |

|---|---|---|

| Resistor Elements | General High-Temp Processing | Offers the highest control and stability via resistance. |

| Induction Coils | Rapid Metal Heating | Bypasses thermal transfer lag by heating the material directly. |

| Electron Guns | Precision Melting | Delivers high-energy density to a pinpoint location. |

Engineering Your Outcome

The difference between a failed experiment and a breakthrough often lies in the invisible components we take for granted.

You are not just buying a furnace; you are buying a thermal environment.

At KINTEK, we understand the romance of engineering—the balance between high heat and high safety. We specialize in lab equipment that respects the strict laws of physics, ensuring your resistors don't arc and your samples remain pure.

Whether you need rapid induction speed or the steady hand of graphite resistors, our solutions are built to withstand the pressure of your most demanding research.

Don't let an unseen variable compromise your data.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.