Oxygen is a paradox. Biologically, we cannot survive without it. Materially, it is often a destroyer.

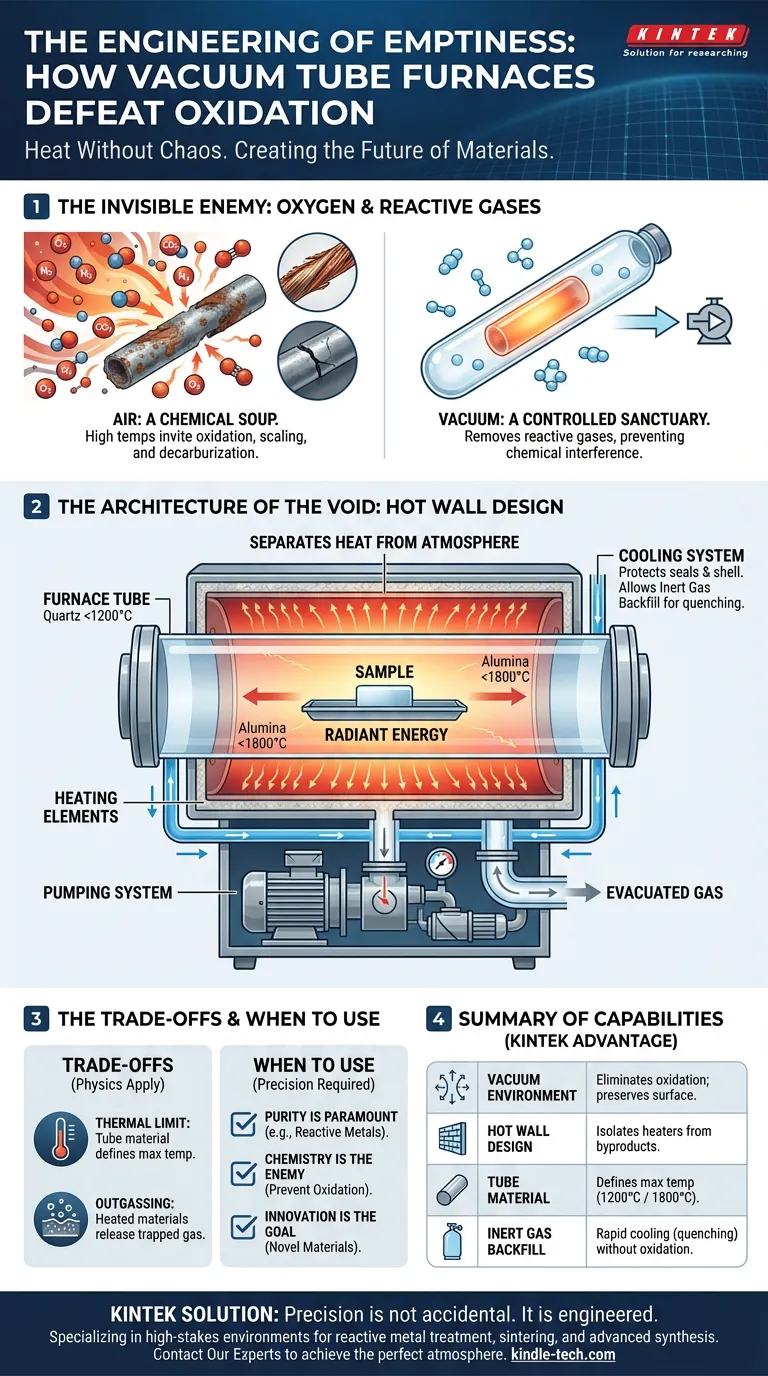

In the world of materials science, air is not a neutral medium; it is a chemical soup. When you heat metal or ceramics in the open air, you invite chaos. Oxygen reacts. Surfaces tarnish. Carbon escapes steel like a ghost leaving a body.

To create the future—whether that means stronger alloys, purer semiconductors, or novel ceramics—we need heat without the chaos.

We need to burn things in nothingness.

Enter the vacuum tube furnace. It is a machine designed to do one specific, difficult thing: separate the thermal energy we need from the atmosphere we don't.

The Architecture of the Void

A vacuum tube furnace is not just an oven; it is a vessel of exclusion.

Its primary function is to heat materials within a sealed tube while maintaining a low-pressure, oxygen-free environment.

The design philosophy is distinct. Unlike other furnaces where heaters might sit directly next to the sample, this uses a "hot wall" design. The heating elements sit outside the tube. They radiate energy through the tube walls to the sample hidden within.

This separation is brilliant in its simplicity. It protects the heating elements from the vacuum process, and it protects the sample from the elements.

The Invisible Enemy: Why We Remove the Air

Why go to the trouble of building a complex vacuum system?

Because at high temperatures, the 21% of our atmosphere that is oxygen becomes incredibly aggressive.

Oxidation

When metals heat up, they want to bond with oxygen. This creates rust, scaling, and tarnishing. If you are annealing a copper wire or brazing a reactive metal, even a trace of oxygen ruins the conductivity and strength.

Decarburization

For steel, the enemy is subtle. Oxygen pulls carbon atoms out of the metal's surface structure. The result is a softer, weaker skin on a hard part—a catastrophic failure waiting to happen in high-stress applications.

By engaging the vacuum pumping system, the furnace evacuates these reactive gases. It creates a sanctuary where heat can do its work without chemical interference.

The Anatomy of Control

While the concept is abstract, the machine is physically robust. A vacuum tube furnace relies on four critical subsystems working in concert.

1. The Furnace Tube

This is the heart of the operation. The sample sits here. The tube must be transparent to heat but impervious to gas.

The material of the tube dictates the limits of the furnace:

- Quartz: Inexpensive and clear, but limited to roughly 1200°C.

- Alumina (Ceramic): Can withstand up to 1800°C, but is brittle and expensive.

2. The Heating System

Surrounding the tube are the resistance wires or graphite heaters. They push electrical current until they glow, transferring energy through the "hot wall" of the tube.

3. The Pumping System

This is the lungs of the machine. One or more pumps work to physically drag gas molecules out of the sealed chamber, lowering the pressure to the desired level.

4. The Cooling System

Heat is hard to contain. To prevent the rubber O-ring seals from melting and the outer shell from warping, a water cooling system often circulates through the furnace jacket.

For the sample itself, operators might backfill the chamber with inert gas (like Argon) to rapidly quench the material, locking in specific microstructures.

The Trade-offs

Engineering is the art of compromise. The vacuum tube furnace is powerful, but it obeys the laws of physics.

The Thermal Limit Because of the "hot wall" design, the tube gets as hot as the sample. You cannot process a material at 2000°C if your tube melts at 1800°C. For extreme temperatures, you would need a "cold wall" furnace (where heaters are inside the vacuum), which is a different beast entirely.

Outgassing Materials are not always solid. When heated, they release trapped gases—a process called outgassing. If not managed by the pumps, these "burps" of gas can ruin the vacuum level and contaminate the batch.

Is This the Right Tool for You?

Not every process requires the complexity of a vacuum. You don't use a scalpel to chop wood.

Consider a vacuum tube furnace if:

- Purity is paramount: You are brazing reactive metals or annealing sensitive parts.

- Chemistry is the enemy: You must prevent oxidation or surface scaling.

- Innovation is the goal: You are synthesizing novel materials that cannot exist in standard air.

If you are simply hardening robust steel where surface finish doesn't matter, a standard atmospheric furnace is faster and cheaper.

Summary of Capabilities

| Feature | Description | The Engineering Benefit |

|---|---|---|

| Vacuum Environment | Evacuated sealed tube. | Eliminates oxidation; preserves surface chemistry. |

| Hot Wall Design | Heaters outside the tube. | Isolates heating elements from process byproducts. |

| Tube Material | Quartz or Alumina. | Defines the maximum temperature (1200°C vs 1800°C). |

| Inert Gas Backfill | Argon/Nitrogen injection. | Allows for rapid cooling (quenching) without oxidation. |

The KINTEK Solution

Precision is not accidental. It is engineered.

When your research or production line demands materials that are chemically pure and structurally perfect, the equipment you choose acts as the gatekeeper.

KINTEK specializes in these high-stakes environments. Our vacuum tube furnaces are designed to handle the rigorous demands of reactive metal treatment, sintering, and advanced material synthesis. We understand that in your lab, "nothingness" (the vacuum) is actually the most important ingredient.

Contact Our Experts to discuss how KINTEK can help you achieve the perfect atmosphere for your next breakthrough.

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- The Architecture of Heat: Why Precision is the Only Variable That Matters

- The Silent Partner in Pyrolysis: Engineering the Perfect Thermal Boundary

- Introducing the Lab Vacuum Tube Furnaces

- Advanced Laboratory Furnaces: Box, Muffle, and Tube Options for High-Temperature Applications

- Ultimate Guide to High Pressure Tube Furnaces: Applications, Types, and Benefits