The Hidden Variable in Heat Treatment

In engineering, we often obsess over what we add to a system. We calculate the temperature, the duration, and the alloy composition.

But often, the most critical factor is what we take away.

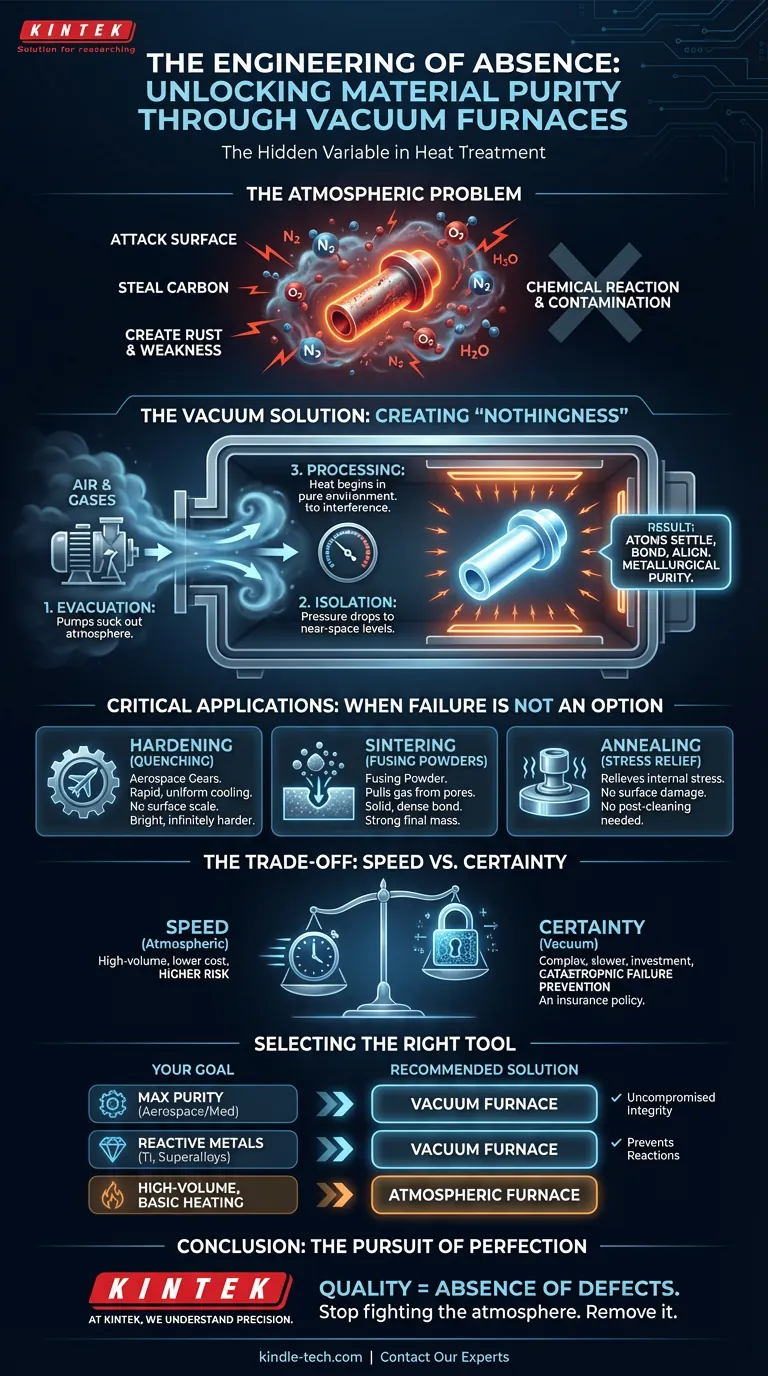

When you heat a metal in the open air, you are not just heating the metal. You are inviting a chemical reaction with the atmosphere. Nitrogen, oxygen, and water vapor—the invisible soup we breathe—become aggressive contaminants at high temperatures.

They attack the surface. They steal carbon. They create rust (oxidation) and weakness.

The vacuum furnace is the engineer’s answer to this chaos. It is a machine designed to create nothingness. By removing the air before the heat rises, it ensures that the only thing changing is the material's structure, not its chemistry.

The Science of the "Void"

To understand the value of a vacuum furnace, you have to look at the microscopic violence that happens in a standard furnace.

In a conventional environment, heat acts as a catalyst. It accelerates oxidation and decarburization. A steel part might enter the furnace strong and exit with a compromised surface layer—a "skin" of weakness that acts as a crack initiation site.

The vacuum furnace solves this by mechanical brute force and elegant physics:

- Evacuation: Powerful pumps suck the atmosphere out of a sealed chamber.

- Isolation: The pressure drops to near-space levels.

- Processing: Only then does the heating begin.

The result is an environment where atoms can settle, bond, and align without interference. It is the closest we get to metallurgical purity.

Critical Applications: When Failure is Not an Option

We do not use vacuum furnaces for everything. They are too slow and too expensive for making garden fences.

We use them when the margin for error is zero. We use them when the "unseen" quality of a material dictates safety.

1. Hardening (Quenching)

In high-stress components like aerospace gears, surface integrity is everything. Vacuum quenching cools the part rapidly and uniformly. Because there is no air, there is no surface scale. The part emerges as bright as it went in, but infinitely harder.

2. Sintering (Fusing Powders)

Sintering involves taking metal powder and fusing it into a solid mass. If air gets trapped between those powder particles, the part is weak. A vacuum pulls the gas out from the pores, ensuring the final bond is solid and dense.

3. Annealing (Stress Relief)

After machining, metals carry internal stress. Annealing relaxes them. Doing this in a vacuum prevents surface damage, meaning you don't have to sandblast or acid-clean the part afterward. It saves a step by preventing a mess.

The Cost of Certainty

There is a psychological trade-off in manufacturing: Speed vs. Certainty.

Vacuum furnaces sit on the extreme end of certainty.

- They are complex: Maintaining a vacuum seal requires meticulous engineering.

- They are slower: Pumping down a chamber takes time that high-volume lines often cannot spare.

- They are an investment: The equipment costs more than standard atmospheric ovens.

But the cost of not using one—in industries like medical devices or jet propulsion—is catastrophic failure. A vacuum furnace is an insurance policy built into the manufacturing process.

Selecting the Right Tool

How do you know if your process requires this level of control? It usually comes down to the reactivity of your material and the criticality of the surface.

| Your Goal | Recommended Solution |

|---|---|

| Maximum Purity (Aerospace/Medical) | Vacuum Furnace |

| Reactive Metals (Titanium, Superalloys) | Vacuum Furnace |

| High-Volume, Basic Heating | Atmospheric Furnace |

| Surface Chemical Changes (Nitriding) | Controlled Atmosphere Furnace |

Conclusion: The Pursuit of Perfection

Quality in materials science is often defined by the absence of defects.

A vacuum furnace is not just a tool for getting things hot. It is a tool for keeping things pure. It represents a commitment to the idea that the environment matters just as much as the temperature.

At KINTEK, we understand this engineer's romance with precision. We specialize in the lab equipment that allows you to control the variables that others ignore. Whether you are sintering advanced ceramics or heat-treating superalloys, our systems are designed to deliver uncompromised integrity.

Stop fighting the atmosphere. Remove it.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

Related Articles

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum