There is a dangerous illusion in electrochemistry.

The illusion is that the experiment begins when you turn on the potentiostat. We believe the science happens in the software, in the voltage ramp, and in the resulting graph.

But the truth is more mechanical. The quality of your data is determined long before the current flows. It is determined in the quiet moments of preparation.

A super-sealed electrolytic cell is not just a container; it is a hermetic universe. Your job is to be the architect of that universe. If the architecture is flawed, the physics will be wrong.

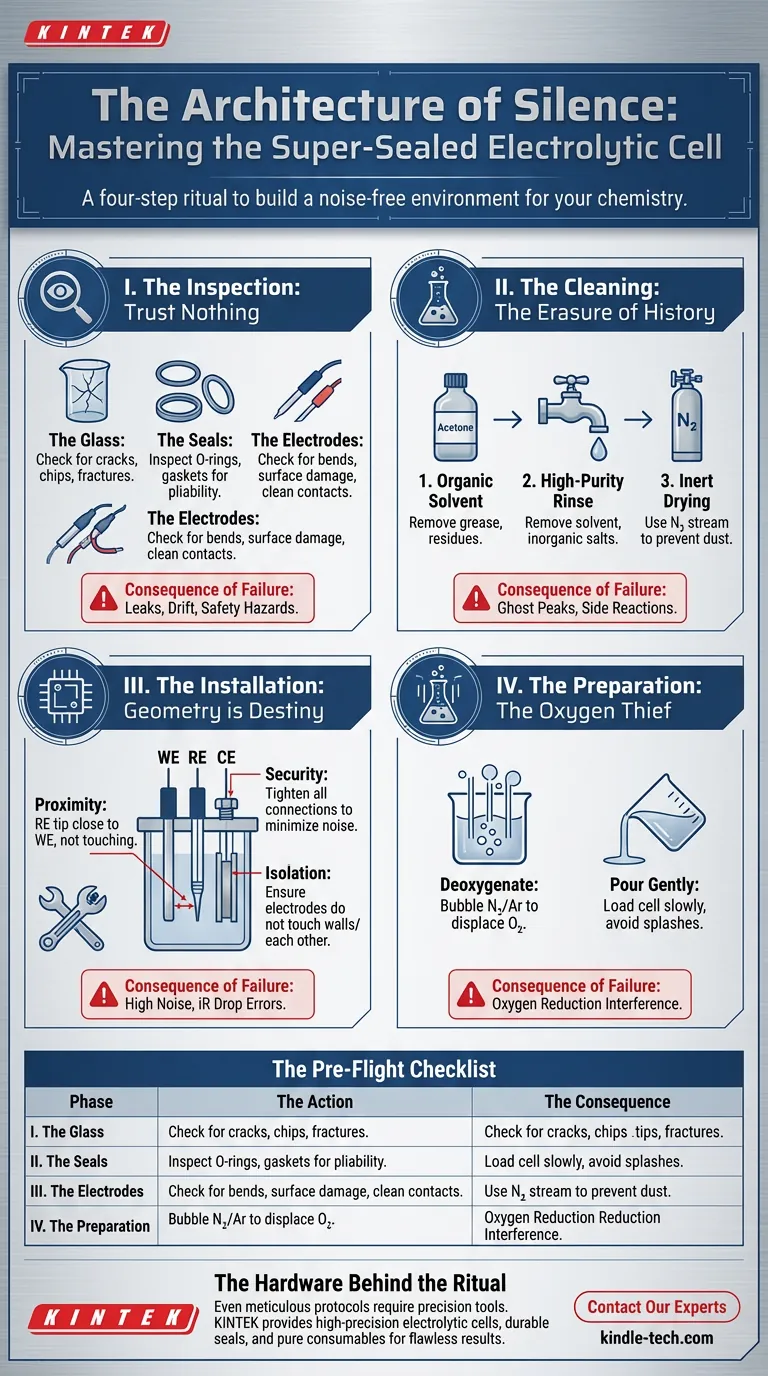

Here is the four-step ritual required to build a noise-free environment for your chemistry.

I. The Inspection: Trust Nothing

In aviation, pilots walk around the plane before every flight. They are looking for the tiny hairline fracture that could turn into a catastrophe at 30,000 feet.

You must do the same with your cell.

A super-sealed system relies on pressure and vacuum. Physical integrity is not a luxury; it is a requirement.

- The Glass: Look for cracks, chips, or fractures. Glass is unforgiving. A micro-fracture is a leak waiting to happen.

- The Seals: Inspect the O-rings and gaskets. Are they pliable? Are they brittle? A hard seal is no seal at all.

- The Electrodes: Check for bends or surface damage. An oxidized clip creates resistance. Resistance creates heat and noise.

If the vessel cannot hold the world out, the experiment is already over.

II. The Cleaning: The Erasure of History

"Clean" is a relative term. To a chef, a plate is clean if it has no food on it. To an electrochemist, a surface is only clean if it has nothing on it.

A fingerprint is a mountain range of oils and salts. A trace of leftover solvent is a competing reactant.

You are not just washing the cell; you are erasing its history. The process must be absolute:

- Organic Solvent: Use ethanol or acetone to strip away grease and organic residues.

- High-Purity Rinse: Follow with deionized water to remove the solvent and inorganic salts.

- Inert Drying: Dry the cell with a stream of nitrogen. Air drying invites dust.

If you skip this, you aren't measuring your analyte. You are measuring your cleaning habits.

III. The Installation: Geometry is Destiny

In a three-electrode system, geometry dictates accuracy.

The electrons need a clear path. If your physical setup is sloppy, your data will be full of "ghosts"—uncompensated resistance (iR drop) and electrical noise.

- Proximity: The reference electrode tip must be close to the working electrode, but never touching. This minimizes voltage drop.

- Security: A loose wire acts like an antenna, picking up background noise from the room. Tighten every connection.

- Isolation: Ensure electrodes do not touch the walls or each other. A short circuit is the end of the line.

Think of this step as tuning an instrument. If the strings are loose, the music will be off-key, no matter how well you play.

IV. The Preparation: The Oxygen Thief

The final step is the most subtle. You must prepare the medium itself.

Oxygen is the great interferer. It is electrochemically active and loves to be reduced. If dissolved oxygen remains in your electrolyte, it will obscure the delicate reactions you are trying to study.

- Filter: Remove particulate impurities.

- Deoxygenate: Bubble inert gas (Nitrogen or Argon) through the solution. You are displacing the atmosphere.

- Pour Gently: Load the cell slowly to avoid splashing. Bubbles clinging to an electrode surface block active sites.

You are creating a blank canvas. Only then can you paint with electrons.

Summary: The Pre-Flight Checklist

| Phase | The Action | The Consequence of Failure |

|---|---|---|

| 1. Inspection | Check glass, seals, and clips. | Leaks, drift, and safety hazards. |

| 2. Cleaning | Solvent, pure water, inert dry. | Ghost peaks and side reactions. |

| 3. Installation | Secure geometry and wiring. | High noise and iR drop errors. |

| 4. Preparation | Deoxygenate and pour. | Oxygen reduction interference. |

The Hardware Behind the Ritual

There is a romance to doing things the hard way, but there is no glory in using bad tools.

Even the most meticulous cleaning protocol cannot fix a poorly manufactured seal or low-grade glass. The integrity of your "hermetic universe" depends on the quality of the materials you build it with.

At KINTEK, we understand that lab equipment is the foundation of truth in science. We provide the high-precision electrolytic cells, durable sealing components, and pure consumables that allow your preparation ritual to yield flawless results.

Don't let equipment failure be the variable you didn't account for.

Visual Guide

Related Products

- Super Sealed Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

Related Articles

- The Glass Heart of the Experiment: Precision Through Systematic Care

- The Architecture of Control: Mastering the Super-Sealed Electrolytic Cell

- The Architecture of Precision: Mastering the Five-Port Water Bath Electrolytic Cell

- The Anchor of Truth: Why Physical Stability Defines Electrochemical Success

- The Vessel of Truth: Why the Container Matters More Than the Chemistry